My new pressure sensor system is giving unexpected readings. How can I determine if the problem is with the voltage output pressure sensor or my data acquisition (DAQ) system?

A systematic troubleshooting approach is the most effective way to isolate the source of error in an instrumentation loop. By separating the sensor from the rest of the system, you can determine if the fault lies with the measurement device or the signal processing hardware. Here is a step-by-step diagnostic guide based on industry best practices.

Featured voltage output pressure sensor products

0-10 Volts Output Pressure Transducers - 0 to 10 volts output pressure transducers with amplified signal conditioning electronics and 3 or 4 wire configuration for generating a 0-10Vdc analog signal which corresponds to a specified pressure range.

0-10 Volts Output Pressure Transducers - 0 to 10 volts output pressure transducers with amplified signal conditioning electronics and 3 or 4 wire configuration for generating a 0-10Vdc analog signal which corresponds to a specified pressure range.  Irrigation water pressure transducer for pressures up to 60 bar - Voltage output pressure transducer with a 0 - 5V dc signal out for measuring irrigation piping water pressure form 0-60bar.

Irrigation water pressure transducer for pressures up to 60 bar - Voltage output pressure transducer with a 0 - 5V dc signal out for measuring irrigation piping water pressure form 0-60bar.

Verify System Basics:

- Power Supply: Ensure the voltage supplied to the sensor is within its specified operating range.

- Wiring: Double-check that the electrical connections are correct.

Isolate and Test the Sensor:

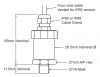

- Disconnect the sensor’s signal wire from your DAQ, PLC, or display.

- Using a calibrated digital voltmeter (DVM), measure the voltage directly across the sensor’s signal output. This provides a direct, unfiltered reading of the sensor’s output.

Perform a Bench Test with a Calibrated Source:

- Connect the sensor to a known, stable pressure source, such as a pressure calibrator or deadweight tester. This allows you to apply precise pressures and validate the sensor’s response.

- Create a data table, recording the sensor’s direct voltage output (from your DVM) at several pressure points across the measurement range (e.g., 0%, 25%, 50%, 75%, and 100% of full scale).

Featured pressure calibration products

Air Pressure Calibrators - Ensure the accuracy of your pneumatic pressure instruments with our range of pressure calibrators, hand pumps, and test gauges.

Air Pressure Calibrators - Ensure the accuracy of your pneumatic pressure instruments with our range of pressure calibrators, hand pumps, and test gauges. ADT681 Digital Pressure Gauge - The ADT681 digital pressure gauge family covers a wide range of pressures from as low as 1 inH20 differential to as high as 36,000 psi gauge.

ADT681 Digital Pressure Gauge - The ADT681 digital pressure gauge family covers a wide range of pressures from as low as 1 inH20 differential to as high as 36,000 psi gauge.

Compare Measured Data to Specifications:

- Calculate the ideal output for each pressure point.

- Factor in the sensor’s allowable tolerances. This includes the accuracy, and the specified zero & span offset range.

- If your DVM readings fall within the calculated range of ideal output plus/minus the combined tolerances, the sensor is performing correctly.

Investigate the Data Acquisition System:

- If the bench test confirms the sensor is healthy, the problem lies downstream in your signal processing chain.

- Input Range: Confirm your DAQ card or PLC analogue input is configured for the correct voltage range.

- Software Scaling: Check the scaling factors used in your software or PLC logic to convert the voltage reading back into a pressure value (e.g., bar, psi). Incorrect scaling is a very common source of error.

By following this process, you can confidently determine whether the issue originates from the voltage output pressure sensor or the instrumentation used to read it.

Featured voltage output pressure sensor products

SSPT Subsea Wet-Mateable Electrical Connector Pressure Sensor - This stainless steel ceramic sensing diaphragm based subsea connector pressure sensor provides a unamplified ratiometric millivolt output or an amplified analogue output signal corresponding to ranges from 0…1 bar (14.50 psi) up to 400 bar ( 5800 psi).

SSPT Subsea Wet-Mateable Electrical Connector Pressure Sensor - This stainless steel ceramic sensing diaphragm based subsea connector pressure sensor provides a unamplified ratiometric millivolt output or an amplified analogue output signal corresponding to ranges from 0…1 bar (14.50 psi) up to 400 bar ( 5800 psi). DMP331 Precision Pressure Transmitter - Stainless steel pressure transmitter with ranges from 100mbar up to 40 bar gauge or absolute. Special options for ATEX , SIL2 and compound ranges.

DMP331 Precision Pressure Transmitter - Stainless steel pressure transmitter with ranges from 100mbar up to 40 bar gauge or absolute. Special options for ATEX , SIL2 and compound ranges.

Related Help Guides

- Choosing calibrator for pressure transmitters

- How to create a list of specification parameters for a pressure sensor

- Checking the LHR error of a 0-5 Vdc output pressure transducer

- Digital sensor for high precision pressure calibration

- What is the difference between a pressure transducer and a transmitter

- Reduce calibration costs of analogue pressure gauges

- How does the accuracy of pressure measurement devices change over time

- Calibration Hand Pump performance depends on test volume

Related Technical Terms

- 4 Wire

- Cardinal Points

- Isolation Diaphragm

- Primary Pressure Reference Standard

- Secondary Pressure Standard

- Stainless Steel Pressure Sensors

Related Online Tools

- Pressure Transmitter 4-20mA Current Output Calculator

- Pressure Sensor Calculator

- DP Flow Transmitter Output Calculator

- Pressure Transducer Millivolt (mV) Output Calculator

- Pressure Transducer 0-10V Voltage Output Calculator

- Pressure Transducer 0-5V Voltage Output Calculator

- Pressure Transducer 1-5V Voltage Output Calculator

- Pressure Transducer 0.5-4.5V Voltage Output Calculator

- Pressure Sensing Errors Calculator

- Pressure Transmitter 0-20mA Current Output Calculator

Related Product and Application Guides

Related Application Questions and Answers

- 20 bar absolute steam pressure transducer

- 5 bar water irrigation pressure transducer with 0 to 5 volt output

- 180 degC pressure sensor for saturated steam up to 10 bar

- 300 foot sea depth waterproof pressure sensor with 0-5V signal

- Using 25 mbar DP sensor on vacuum below 0.2 bar absolute

- Data acquisition module 0-10Vdc output pressure gauge

- Zero & Span calibration adjustable signal output pressure transducers

- Leak testing at 0.5 bar to detect 200 Pascal pressure drop

- Low delta P sensor with 200mmH2O range and response time < 5ms

- Pneumatic air cylinder pressure transducer monitoring up to 150 psi with Arduino

- 200 bar pressure sensor to interface with Arduino board

Contact us about this Diagnosing incorrect readings from a pressure measurement system page to request more information, or to discuss your application requirements.