Learn how a differential pressure sensor (dp sensor) can be used to measure a partial vacuum as a negative pressure relative to local surrounding air pressure.

- The vacuum range covers any pressure lower than the current atmospheric pressure.

- In industry, vacuums are typically measured by how much lower they are than normal atmospheric pressure.

- Gauge pressure sensors are normally used to measure the difference between vacuum pressure and the surrounding air pressure.

- The output signal of these sensors can be set up in two ways – increasing as the vacuum gets stronger or decreasing as the vacuum gets weaker.

- Differential pressure sensors can be used to measure vacuums by connecting normal air pressure to the positive side and vacuum to the negative side.

- Many differential pressure sensors allow you to configure the output signal in the reverse direction so you can measure vacuum as an increasing or decreasing quantity.

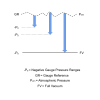

The vacuum range is any pressure that is lower than the current atmospheric pressure. If no atmospheric pressure is specified then an average at sea level is used, which is typically 1 standard atmosphere (101,325 pascals absolute), or 1 bar absolute (100,000 pascals absolute) for convenience, since both values are approximately the same.

In the industrial world where partial vacuums are commonly used as part of the manufacturing process, and they are typically specified as the amount of pressure below atmospheric pressure. Since the reference point is atmospheric pressure, a gauge reference pressure sensor, which is open to atmospheric pressure on the reverse side of the sensing diaphragm, is normally what is used to compare pressures in the vacuum range to the surrounding air pressure.

The output signal can be setup in two different ways with a zero output reading at ambient air pressure, and the full range output set at the highest operational vacuum, or vice versa reversing the output, so it is measuring in the direction of increased pressure rather than vacuum. In both cases it is measuring the vacuum pressure relative to surrounding ambient air pressure.

A differential pressure sensor is designed for pressure to be applied on both sides, and the mechanical design and fittings are designed to be used over a wide range of pressures including the vacuum range. It is therefore possible to leave the positive side of a dp sensor open to surrounding air pressure, to create a gauge reference, and then apply the vacuum to be measured to the negative side.

The vacuum pressure applied to the negative side connection of the dp sensor, will now be measured relative to local air pressure, in the same way as a negative gauge pressure sensor measures over the vacuum range. Therefore the output of the dp sensor will increase as the vacuum increases.

In some applications it is required to reverse the output signal, so that full scale output is measured when the pressure returns to atmospheric pressure, and zero output when the highest vacuum pressure is achieved. Since many types of differential pressure sensor include the ability to re-range the output signal, it is possible to reverse the signal so that it increases as the pressure is increased instead.

Here are the steps on how to measure vacuum as a gauge pressure using a differential pressure sensor:

- Choose a Suitable DP Sensor: Select a differential pressure sensor capable of measuring the expected vacuum pressure range.

- Establish a Gauge Reference: Connect the negative side of the DP sensor to atmospheric pressure. This will become your reference point against which the vacuum will be measured.

- Apply the Vacuum: Connect the vacuum source you want to measure to the positive side of the DP sensor.

- Interpret the Output: The output of the DP sensor will now indicate the difference between atmospheric pressure (gauge reference) and the pressure of the vacuum being measured. Since your reference is atmospheric pressure, the dp sensors output will directly represent the gauge pressure of the vacuum.

Additional Notes:

- Some DP sensors may have the ability to invert their output. If so you will be able to change the output so that it increases as the vacuum decreases, and gets closer to atmospheric pressure.

Related Help Guides

- How do you measure flow rate with a dp cell

- Measuring liquid level in a tank using a dp sensor

- Can you have a minus 20 psi gauge vacuum measurement range

- Measuring density of a liquid using a dp sensor

- Measuring the difference in air pressure between rooms

- Measuring vacuum with negative gauge or absolute ranges

- What is the difference between gauge and absolute pressure measurement

- What is the difference between vacuum and absolute pressure

- Can you measure vacuum using a gauge pressure range

- What does negative and positive gauge pressure mean

- Measuring negative pressure using a positive differential pressure range

- What can a DP sensor be used to measure beyond differential pressure?

Related Technical Terms

- Dry/Dry

- Gauge Reference Pressure

- Negative Gauge Pressure

- Reference Pressure

- SG – Sealed Gauge

- Static Line Pressure

- Vented Cable

- Vented Gauge

- Wet/Dry

- Wet/Wet

Related Online Tools

- High and Low Side Pressure to Differential Pressure Calculator

- Gauge + Barometric to Absolute Pressure Calculator

- Suction Pressure to Vacuum Calculator

- DP Flow Transmitter Output Calculator