Determining whether you need gauge or absolute reference pressure is a very important to selecting the right pressure range for a pressure instrumentation. If you get it wrong your measurements are going to be out by approximately 1 bar, which will be a significant error if you require low range device.

If you have taken delivery of a pressure measuring device with the wrong pressure reference, this will normally mean that it will have to be sent back to the manufacturer to modify or build a replacement because a change to the pressure reference will often often require a different sensing element which is a core component of pressure measurement devices.

What is gauge pressure?

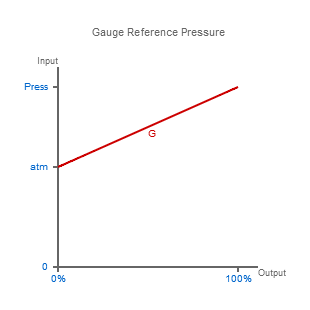

The most common pressure reference is gauge pressure which is signified by a ‘g’ after the pressure unit e.g. 30 psi g, this indicates that the pressure measured is the total pressure minus atmospheric pressure. There are two types of gauge reference pressure: vented gauge (vg) and sealed gauge (sg),

The most common pressure reference is gauge pressure which is signified by a ‘g’ after the pressure unit e.g. 30 psi g, this indicates that the pressure measured is the total pressure minus atmospheric pressure. There are two types of gauge reference pressure: vented gauge (vg) and sealed gauge (sg),

A vented gauge pressure transmitter for example allows the outside air pressure to be exposed to the negative side of the pressure sensing diaphragm via a vented cable or a hole on the side of the device, so that it always measures with reference to the changing ambient barometric pressure. Thus a vented gauge reference pressure sensor reads zero pressure when the process pressure connection is held open to atmospheric air.

A sealed gauge reference is very similar except that atmospheric pressure is sealed on the negative side of the diaphragm. This is usually adopted on high pressure applications such as measuring hydraulic pressures where atmospheric pressure changes will have negligible effect on the accuracy of the sensor so venting is not necessary. This also allows manufacturers to provide secondary pressure containment for extra protection if the burst pressure of the sensing diaphragm is exceeded.

There is another way of creating a sealed gauge reference and this is to seal a high vacuum on the reverse side of the sensing diaphragm. Then by adjusting the electronics, the output signal is offset by 1 bar so the pressure sensor reads close to zero when measuring atmospheric pressure.

A sealed gauge reference pressure transducer will never read exactly zero when left open to atmospheric air, because atmospheric pressure is always changing and the reference in this case is fixed at a nominal 1 bar.

What is absolute pressure?

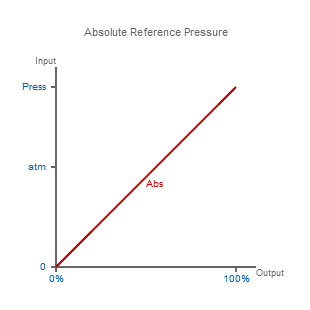

An absolute pressure measurement is one that is referred to a perfect vacuum. The best example of an absolute referenced pressure is the measurement of barometric pressure.

An absolute pressure measurement is one that is referred to a perfect vacuum. The best example of an absolute referenced pressure is the measurement of barometric pressure.

In order to produce an absolute pressure sensor, one method is for a manufacturer to seal a high vacuum behind the sensing diaphragm. Therefore if you vent the process pressure connection of an absolute pressure transmitter to ambient air pressure, it will read the local barometric pressure.

When to measure absolute and gauge pressure?

This is not always straightforward but generally if you want to measure or control a pressure that is influenced by changes in atmospheric pressure, e.g. the level of liquid in an open tank or the output pressure of an air compressor; you would use a vented gauge pressure instrument since you are interested in the pressure reading minus the atmospheric pressure component.

If you want to measure pressures that are not influenced by changes in atmospheric pressure, e.g. leak testing a completely sealed non-flexible container, you would use an absolute pressure sensor. If a gauge pressure sensor was used instead to measure the container pressure, and the barometric pressure changed, then the sensor’s reading would change, despite the fact that the pressure in the container remains the same.

Gauge & Absolute Pressure Help

Identifying gauge or absolute device

How can you quickly tell if you have a gauge or absolute device?

When you vent the pressure connection of the device to ambient air pressure, it will read close to zero if it is gauge reference device, and around 1 bar or equivalent, if it is an absolute reference device.

Applications for gage and absolute pressure

What are the applications for measuring absolute pressure and gage pressure, where do you use absolute pressure and where do you use gage pressure when measuring pressure. Please can you explain with an example?

The majority of applications use a gage reference pressure sensing device, which means the measurement of pressure relative to atmospheric pressure. The reason why this is such a common reference for measuring pressure is because any type of chamber or pipe will equalise with atmospheric pressure when vented. This is therefore the natural starting point to measure pressure for the majority of processes and test procedures, because it saves the user from having to subtract atmospheric pressure from every reading to determine the change in pressure.

For absolute pressure the applications tend to be more specialised, such as gas analysis, ocean depth, altimeters, interferometers, engine air intake performance and moisture measurement to name a few.

Sealed Gauge vs Absolute pressure range

What’s the difference between a sealed gauge pressure range and an absolute pressure range?

The difference between the two is 1 bar, sealed gauge ranges are measured in relation to 1 bar above perfect vacuum (approximately atmospheric pressure), and absolute ranges are measured in relation to a perfect vacuum.

For example:

1000 bar sealed gauge = 1001 bar absolute

Converting 30 psi g to an absolute pressure

If the gauge pressure is 30psi what is the corresponding absolute pressure?

A gauge pressure can be converted into an absolute pressure by adding it on to the current reading of atmospheric pressure. For example if the atmospheric pressure is 14.7psi absolute, 30 psi gauge would translate to 44.7 psi absolute.

Related Help Guides

- How do you choose the correct pressure range for a pressure sensor

- Can you have a minus 20 psi gauge vacuum measurement range

- Measuring vacuum with negative gauge or absolute ranges

- Can you measure vacuum using a gauge pressure range

- What does negative and positive gauge pressure mean

- Measuring negative pressure using a positive differential pressure range

- Pressure device not reading zero? Get troubleshooting tips

- What is the difference between sealed gauge and vented gauge reference?

- Simulating 8000 foot altitude with a pressure gauge

- What does the suffix a, abs, d, dp and diff, g, rel and sg mean after the pressure units in a pressure range?

- Using an Absolute Sensor to Measure Gauge Reference Pressure

- Converting non-vented depth readings & barometric pressure to true depth

- Using Sealed Gauge Reference Pressure Sensing Devices

- Output signal orientation for a negative gauge pressure range