A guide to differential pressure measurement including explanations, applications and choice of products for measuring pressure with an differential pressure.

A guide to differential pressure measurement including explanations, applications and choice of products for measuring pressure with an differential pressure.

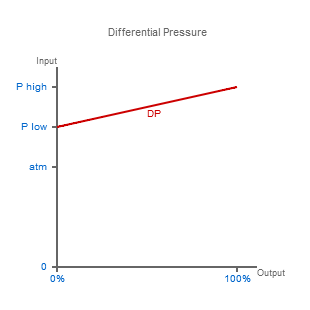

Differential pressure is the difference in pressure between two separate points.

A differential pressure can be measured between two points on independent systems or between two different points on the same system.

Differential Pressure Transmitters - Differential pressure transmitters for measuring the DP of fluids and gases across particle filters and along a length of pipe to monitor flow.

Differential Pressure Transmitters - Differential pressure transmitters for measuring the DP of fluids and gases across particle filters and along a length of pipe to monitor flow. Low Differential Pressure Transmitters - Low differential pressure transmitters for measuring small pressure differences between two measurement points on across ventilation fans, air filters or clean room walls.

Low Differential Pressure Transmitters - Low differential pressure transmitters for measuring small pressure differences between two measurement points on across ventilation fans, air filters or clean room walls. Wet / Wet Differential Pressure Sensors - Wet/Wet differential pressure transducers and transmitters which are compatible with liquids on both positive and negative side process connections.

Wet / Wet Differential Pressure Sensors - Wet/Wet differential pressure transducers and transmitters which are compatible with liquids on both positive and negative side process connections. Differential Pressure Voltage Output Transducers - Differential pressure transducers with amplified volts output for measuring the dp of liquids and gases.

Differential Pressure Voltage Output Transducers - Differential pressure transducers with amplified volts output for measuring the dp of liquids and gases.

Applications

The main use for a differential pressure sensor is to measure the difference in fluid or gas pressure across a restriction in a pipe. The flow can then be determined by converting the differential pressure reading with bernoulli’s equation. Since flow is proportional to the square root of the differential pressure in a closed pipe it is sometimes preferred to use a square root output signal from the differential pressure sensor to simplify the conversion to a flow measurement.

Other applications for measuring differential pressure are as follows:

Hydrostatic level measurement of a tank’s content, where the gas at the top of the tank is not vented. The difference in pressure between the bottom and the top is measured to determine the true hydrostatic pressure.

Leakage monitoring by measuring the difference in pressure between a controlled reference pressure and the component under test pressurised to the same pressure.

Airspeed using a Pitot tube which provides two air channels, one for measuring the total air pressure facing the airflow and the other for the static pressure measured perpendicular to the air-flow. The difference between the two channels provides the air velocity pressure. This method is used on aircraft to measure air speed and in wind tunnels to simulate air velocity for testing the aerodynamics of an object.

Questions & Answers

Differential vs Gauge

When do you need to measure differential pressure instead of gauge pressure?

You would you use a differential when you need to measure pressure between 2 connection points, and when the reference pressure (negative side) is not the same as atmospheric pressure.

Which side of DP transmitter to connect to vacuum

Which side of the impulse line connections for a dp transmitter is the blower vacuum or suction side?

If the output of the dp transmitter is scaled for a positive pressure range, e.g. 0 to +1 bar = 4 to 20 mA, then you can measure 0 to -1 bar suction but connecting the vacuum to the negative side, and leaving the positive side vented to atmosphere.

Related Help Guides

- Measuring vacuum as a negative gauge pressure using a dp sensor

- How do you measure flow rate with a dp cell

- Measuring liquid level in a tank using a dp sensor

- Measuring density of a liquid using a dp sensor

- Measuring the difference in air pressure between rooms

- Measuring negative pressure using a positive differential pressure range

- What can a DP sensor be used to measure beyond differential pressure?

- Measuring flow rate of a liquid or gas using a dp sensor

- Measuring gauge pressure using a dp sensor

- Measuring absolute pressure using a dp sensor

- Measuring barometric pressure using a dp sensor

- Measuring vacuum as an absolute range using a dp sensor

- Measuring liquid level in a sealed tank with a hydrostatic pressure sensor

- What does the suffix a, abs, d, dp and diff, g, rel and sg mean after the pressure units in a pressure range?