A guide on what to consider when choosing pressure calibration equipment for calibrating pressure transmitters.

A guide on what to consider when choosing pressure calibration equipment for calibrating pressure transmitters.

Required accuracy

First you must determine the highest overall accuracy you will need to achieve for the pressure transmitters you will be calibrating. This does not necessarily have to be the manufacturer’s specification since very often the pressure transmitter accuracy is much better than the required system accuracy.

Since the required accuracy is not a parameter that is usually compromised, eliminating portable pressure calibrators without the required accuracy has to be the first step in narrowing the choices.

Ideally a 10 to 1 ratio is recommended for the difference in accuracy between the pressure transmitter and the pressure calibrator, so that no significant extra uncertainty is introduced into the measurements by the pressure calibrator.

However this is not always practical especially when calibrating high accuracy smart pressure transmitters and it is not unusual for a pressure calibrator with a much closer ratio to be used instead. In these cases the uncertainty of the pressure calibration equipment should also be considered in the overall system uncertainty budget.

Connecting device under test

To connect the pressure calibrator you will need to isolate the pressure transmitter under test from the system so that only a small volume will need to be pressurised. Typically a 2 way or a 3 way valve is included in the pressure transmitter installation so that it can be isolated and removed for test or connected to a pressure calibrator in-situ.

Generating test pressures

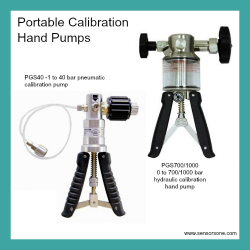

The next consideration is how you are going to generate pressures. It is possible to source pneumatic calibration hand pumps which generate pressures up to 40 bar, however if the volume is too great you may struggle to achieve the manufacturer’s maximum pressure rating.

A hydraulic pump will be needed to achieve calibration pressures above 40 bar.

A hydraulic pump will be needed to achieve calibration pressures above 40 bar.

In order to precisely set pressures it is important that a volume adjuster is incorporated into the calibration hand pump. This will enable each calibration set-point to be applied in one direction without over-shoot so that no pressure hysteresis is introduced into the calibration results.

To save on the number of pieces of test equipment which are carried around, some pressure calibrators include integral hand pumps and volume adjusters. These pressure calibrators are very convenient for portable use but when it comes to sending them away for servicing or switching pressure ranges there is no way to separate the pump from the pressure calibrator.

Measuring 4-20mA output

To measure the output signal of a pressure transmitter you can either break into the system current loop to measure the 4 to 20mA signal using a current meter or you can disconnect the pressure transmitter entirely and use a current meter that also has a loop supply to provide power to the pressure transmitter.

To measure the output signal of a pressure transmitter you can either break into the system current loop to measure the 4 to 20mA signal using a current meter or you can disconnect the pressure transmitter entirely and use a current meter that also has a loop supply to provide power to the pressure transmitter.

Again you can cut down on the number of test equipment by selecting a pressure calibrator that has an integral current meter with a loop power supply. This is particularly useful if the pressure calibrator includes a data logging function, because the calibration results can be stored in the memory for processing and producing a calibration certificate without the need to write down the calibration results.

Overall calibration accuracy

It is often overlooked but the overall accuracy of pressure calibration should also include the accuracy of the current meter. Another calibration error which should be investigated is the temperature error associated with both the pressure calibrator and the current meter. Some manufacturers will quote an overall accuracy for their pressure calibrator over a typical ambient temperature range, while others will quote the temperature errors separately. It is therefore important to examine a little more closely what makes up the accuracy statement on the data sheet when comparing one pressure calibrator with another.

Calibrator accuracy stability

Lastly it is important to point out that no portable pressure calibrator is perfectly stable and most manufacturers will include a stability statement which is either quoted separately or combined with the overall accuracy statement to provide a 3, 6 or 12 month figure. From this combined accuracy and stability figure you will be able to determine the re-calibration period for the portable pressure calibrator. Since the performance of individual instruments can vary, the re-calibration period can be widened if before and after calibration data shows that the pressure calibrator is holding its accuracy over time and this will save on re-calibration costs.

Related Help Guides

- Reduce calibration costs of analogue pressure gauges

- How does the accuracy of pressure measurement devices change over time

- Calibration Hand Pump performance depends on test volume

- Checking the LHR error of a 0-5 Vdc output pressure transducer

Related Technical Terms

Related Online Tools

- Pressure Transducer Millivolt (mV) Output Calculator

- Pressure Transmitter 4-20mA Current Output Calculator

- DP Flow Transmitter Output Calculator

- Pressure Transducer 0-10V Voltage Output Calculator

- Pressure Transducer 0-5V Voltage Output Calculator

- Pressure Transducer 1-5V Voltage Output Calculator

- Pressure Transducer 0.5-4.5V Voltage Output Calculator

- Pressure Sensor Calculator

- Pressure Sensing Errors Calculator

- Pressure Transmitter 0-20mA Current Output Calculator