Rangeable DP Cell current loop process transmitter for monitoring differential pressures in a heavy duty process plant environment.

Product Parameters

- Pressure Ranges: from 0-75mbar up to 0-20bar differential with 10:1 turndown ratio

- Static Line Pressures: 130 bar, including one side only protection

- Accuracy: 0.1% full scale (IEC60770)

- Output Signal: 4-20mA with HART coms, 2 wire loop, linear or sqrt extraction

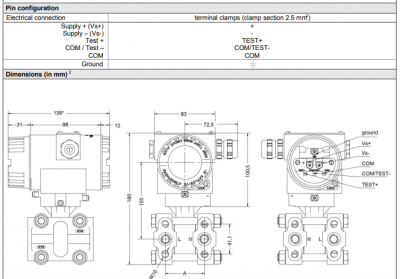

- Electrical Connections: Terminal clamps with M20 x 1.5 cable gland

- Pressure Connnection: 1/4-18 NPT female

- Special Features: HART communications compatible, mechanical stops for overpressure protection, 10 to 1 range turn-down, ATEX approved intrinsic safety or flame proof, linear or square root extraction signal

- Special Options: Integrated local readout display

- Media Compatibility: Stainless steel 316L pressure port and diaphragm with FKM or EPDM seals

- Dimensions: 125 x 82 x 198 mm including electronics housing

- Weight: min 3.5kg

Product Description

The XMD has a standard process configuration with kidney flange mounting arrangement and large accessible electronic housing.

Other features include ATEX intrinsic safety or flameproof, linear or square root extraction 4-20mA output, HART communications, 10 to 1 turndown ranging, LCD readout and 130 bar overpressure protection on one side.

The XMD process DP cell is designed for use in control and monitoring applications on process sites such as oil refineries, pharmaceutical plant, chemical manufacture, power stations, food processing and paper mills.

HART communications is enable as standard allowing the operator to access device information such as type, range and serial number and carry out re-ranging or re-calibration procedures via a HART compatible programming handset.

For convenient stocking of spares and rapid configuration across a number of different applications the 4-20mA output of the transmitter can be rescaled down to 1/10 of the nominal pressure range.

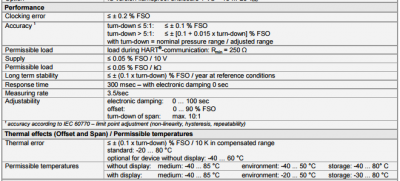

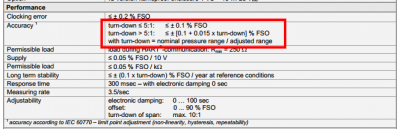

A 0.1% of full scale is maintained down to 1/5 of the range beyond which the accuracy will gradually decrease to a maximum of 0.25% at 1/10 of the nominal range.

The XMD HART pressure transmitter is adaptable to many different purposes on a process site.

The output can be switched to a square root extraction for use as a flow measurement device.

The negative port can be left vented to create a gauge reference process transmitter, it can be installed with an IS barrier for use in a area where an explosion caused by gas or dust is a potential hazard.

Product Applications

Natural gas filter monitoring

Monitoring the pressure drop across a filter where the media is natural gas at 2.5 bar line pressure. If the filter is clean the pressure drop across the filter will not to exceed 10mbar (4″WC). If the filter is blocked the maximum pressure drop allowed is 20mbar (8″WC).

- SKU ID: s1-xmd-0001

- Part No: 340-0750-AN-I-1-AK0-N56-1-1-000

- Upper Pressure Range Limit: 0 to 75 mbar differential

- Factory Set Pressure Range: 0 to 30 mbar

- ATEX Approval Type: Intrinsic safety

- Output Signal: 4 to 20 mA, 2 wire with HART communications

- Accuracy: 0.1% full scale

- Diaphragm Material: Stainless steel 316L

- Media Exposed Seals: FKM

- Process Connection Material: Stainless steel 316L

- Process Connection: 1/4-18 NPT female

Product Help

Wiring connections & IP rating

How do you connect electrical wires to this sensor and what is the IP rating?

The wiring connections are accessed by removing the screw on cap to reveal the terminal clamps. The cable is fed through the M20x1.5 cable gland where the individual wires can then be connected to the terminal clamps. The enclosure has a IP67 ingress protection rating.

Jet A-1 kerosene fumes

I’m looking for a flameproof approved pressure transmitter to measure air and Jet A-1 kerosene fumes up to 40 mb pressure?

The XMD is available as a flameproof approved version, certified to II 2G Ex d IIC T5 Gb, and the standard 75 mbar range can be re-ranged to 0 to 40 mbar for measuring the kerosene fumes & air mixture.

- SKU ID: s1-xmd-0008

- Part No: 340-0750-A0-G-1-AK0-N56-1-1-000

- Upper Pressure Range Limit: 0 to 75 mbar differential

- Factory Set Pressure Range: 0 to 40 mbar

- ATEX Approval Type: Flameproof

- Output Signal: 4 to 20 mA, 2 wire with HART communications

- Accuracy: 0.1% full scale

- Diaphragm Material: Stainless steel 316L

- Media Exposed Seals: FKM

- Process Connection Material: Stainless steel 316L

- Process Connection: 1/4-18 NPT female

- Optional Extras: Integrated LCD display

10 mbar dp with 20 bar system pressure

Do you have a differential pressure transmitter that can measure very low dp of 0.5 – 10 mbar, at a system pressure of up to 20 bar?

A 70 mbar range XMD can be down-ranged to 10 mbar, and will withstand system pressure up to 130 bar.

- SKU ID: s1-xmd-0007

- Part No: 340-0750-A0-I-1-AK0-N56-1-1-000

- Upper Pressure Range Limit: 0 to 75 mbar differential

- Factory Set Pressure Range: 0 to 10 mbar

- ATEX Approval Type: Intrinsic safety

- Output Signal: 4 to 20 mA, 2 wire with HART communications

- Accuracy: 0.1% full scale

- Diaphragm Material: Stainless steel 316L

- Media Exposed Seals: FKM

- Process Connection Material: Stainless steel 316L

- Process Connection: 1/4-18 NPT female

- Optional Extras: Integrated LCD display

15 mbar dp with 1.4 bar line pressure

I’m looking for a wet wet differential pressure sensor with a range from 0-15 mbar, which can withstand a line pressure up to 1.4 bar and vacuum up to 0.75 bar?

A 75 mbar standard range XMD can be re-ranged to measure over 0 to 15 mbar. The line pressure rating is 130 bar max.

- SKU ID: s1-xmd-0006

- Part No: 340-0750-AN-I-1-AK0-N56-1-1-000

- Upper Pressure Range Limit: 0 to 75 mbar differential

- Factory Set Pressure Range: 0 to 15 mbar

- ATEX Approval Type: Intrinsic safety

- Output Signal: 4 to 20 mA, 2 wire with HART communications

- Accuracy: 0.1% full scale

- Diaphragm Material: Stainless steel 316L

- Media Exposed Seals: FKM

- Process Connection Material: Stainless steel 316L

- Process Connection: 1/4-18 NPT female

10:1 turndown ratio explanation

Please can you explain what a 10 : 1 turndown ratio means and how this affect the accuracy?

Turndown refers to how much you can rescale the output, so the 4-20mA output of a 0-75 mbar base range could be re-scaled to 0-7.5mbar. You can either use a third party HART communicator or the LCD display push buttons to re-scale the output.

The accuracy statement for room temperature accuracy is included below, but bear in mind that you are still using the same sensing diaphragm, so the sensor thermal errors, stability, repeatability & hysteresis will all degrade with turndown.

Biogas blower vacuum 0-10 mbar

I’m looking for a vacuum pressure transmitter to use on biogas to help control a blower between 0-10mbar?

We would suggest the XMD differential pressure transmitter with a 75 mbar pressure range which can be turned down to measure over 0-10 mbar, and has all stainless steel 316L wetted parts. You can use the XMD to measure negative pressure simply by the lowest pressure side to the negative port.

- SKU ID: s1-xmd-0005

- Part No: 340-0750-A0-I-1-AK0-N56-1-1-000

- Upper Pressure Range Limit: 0 to 75 mbar differential

- Factory Set Pressure Range: 0 to 10 mbar

- ATEX Approval Type: Intrinsic safety

- Output Signal: 4 to 20 mA, 2 wire with HART communications

- Accuracy: 0.1% full scale

- Diaphragm Material: Stainless steel 316L

- Media Exposed Seals: FKM

- Process Connection Material: Stainless steel 316L

- Process Connection: 1/4-18 NPT female

- Optional Extras: Integrated LCD display

Turndown Accuracy

What would be the accuracy of the XMD if the pressure range is re-scaled?

The accuracy is 0.1% of any range up to a 5:1 turndown, and beyond that it will 0.1 + (0.015 x Turndown) %FS, so 10:1 turndown would be 0.25% of scaled range.

Sealing material used in wetted parts

What type of FKM seal is used to seal the DP cell to the bolted process connection flanges on the XMD process pressure transmitter?

The XMD O ring seal is made from Viton 70 GLT.

Purpose of FKM seal material

I plan to connect the XMD DP transmitter to two pressure taps on a pipe carrying liquids which could be water or oil. I am not sure what seal gasket material to select, perhaps you could explain what this is and what type of material I should choose?

The process mounting assembly and differential pressure sensing cell of the XMD pressure transmitter are bolted together. The gasket is used to provide a pressure seal on the media side of the components which are clamped together. The standard selection is FKM which is a Fluoroelastomer material. FKM has good compatibility with hydrocarbons and solvents and therefore it will be fine if used with water or oil. However, some hydraulic oils can be highly corrosive so we would suggest verifying material compatibility if you intend to use on hydraulic oil.

Exhaust fan blower

We are looking for transducers to signal the pressure differential of ducts between upstream and downstream fan blowers. The blow and suck system pressure differential signal will be sent to a motor control unit on the suck (downstream) side to speed-up or slow-down the blower in order to balance the flow of moisture laden exhaust at approximately 180F. What could measure this differential pressure?

The XMD has an all welded stainless steel wet/wet design and is compatible with most common liquids on both the positive and negative side.

The exhaust temperature is close to the upper limit process temperature, however, since you will need to run pipe work to each pressure port, the gas will cool down to a temperature close to ambient, so the exhaust temperature should not be an issue.

Exhaust duct negative pressure to -10inH2O

I’m looking for a process transmitter with a digital pressure gauge to measure duct pressure. I want to measure negative pressure down to minus 10 inH2O in an exhaust duct referenced to atmosphere. Also it is a corrosive environment being sensed inside the duct, but it is not corrosive around the outside of the sensor, only the wetted parts. Ideally I am looking for Hastelloy wetted parts.

We would suggest using the XMD with a low pressure range, plus the optional LCD display & Hastelloy C276 diaphragm. if the exhaust is connected to the negative port and the positive port is left open to atmosphere, it will read the negative pressure:

- SKU ID: s1-xmd-0002

- Part No: 340-0750-A0-I-1-AK0-N56-H-1-000

- Upper Pressure Range Limit: 0 to 75 mbar differential

- Factory Set Pressure Range: 0 to 10 inH2O

- ATEX Approval Type: Intrinsic safety

- Output Signal: 4 to 20 mA, 2 wire with HART communications

- Accuracy: 0.1% full scale

- Diaphragm Material: Hastelloy C276

- Media Exposed Seals: FKM

- Process Connection Material: Stainless steel 316L

- Process Connection: 1/4-18 NPT female

- Optional Extras: Integrated LCD display

Anaerobic digester gas manifold pressure

I’m looking for a transmitter for anaerobic digester gas manifold pressure monitoring with a pressure range of 0 to 12 inches of water column.

The XMD lowest range of 75 mbar can be turned down to 0 to 12 inH2O which is equivalent to ~30 mbar so within the 10:1 allowed turndown ratio.

- SKU ID: s1-xmd-0003

- Part No: 340-0750-A0-I-1-AK0-N56-1-1-000

- Upper Pressure Range Limit: 0 to 75 mbar differential

- Factory Set Pressure Range: 0 to 12 inH2O

- ATEX Approval Type: Intrinsic safety

- Output Signal: 4 to 20 mA, 2 wire with HART communications

- Accuracy: 0.1% full scale

- Diaphragm Material: Stainless steel 316L

- Media Exposed Seals: FKM

- Process Connection Material: Stainless steel 316L

- Process Connection: 1/4-18 NPT female

- Optional Extras: Integrated LCD display

Ashdown Control BDXD0FHS860AEN/WDP replacement

I have an old Ashdown Control BDX DP transmitter with part number BDXD0FHS860AEN/WDP would I be able to replace it with the XMD?

Yes you can because it is a very similar kind of differential pressure transmitter with high overload protection on either pressure ports. The main differences between the two DP transmitters is as follows:

- Internal FKM seals instead of Buna N

- No optional mounting bracket, although there are mounting holes on the flanges

- 1/4 NPT female instead of 1/4 BSP P female process connections

We would suggest the following XMD spec to replace your BDX part number:

- SKU ID: s1-xmd-0004

- Part No: 340-4000-A0-I-1-AK0-N56-1-1-000

- Upper Pressure Range Limit: 0 to 400 mbar differential

- Factory Set Pressure Range: 0 to 400 mbar

- ATEX Approval Type: Intrinsic safety

- Output Signal: 4 to 20 mA, 2 wire with HART communications

- Accuracy: 0.1% full scale

- Diaphragm Material: Stainless steel 316L

- Media Exposed Seals: FKM

- Process Connection Material: Stainless steel 316L

- Process Connection: 1/4-18 NPT female

- Optional Extras: Integrated LCD display

FSO accuracy meaning

I presume FSO means Full Scale Output, but for a 75 mbar range, does this mean that for a turndown to 5:1, the error is 0.1% of 75mbar, or does it mean that FSO refers to the new full scale, e.g. new maximum set point of 15 mbar?

FSO refers to the 4-20mA, or the turn down span, so 0.1% of the new span up to 5:1 limit. Beyond this the error will degrade as the maximum turndown is reached, ultimately the worst % error being 0.25% of 7.5mbar at 10:1 turndown.

Supply voltage variation effect on accuracy

Can you also explain the line describing the performance for the supply voltage of 0.05% FSO / 10V?

This relates to the direct effect on the output signal for a change in the supply voltage. Typically this will be very small if using a regulated supply which has a small variation of say +/-1% , which on a 24Vdc power supply would result in an error no worse than 0.0012% FSO.

Calibration supply voltage

What supply voltage is used when calibrating the XMD in the factory?

All calibration is performed with a supply voltage of 24 volts dc.

Related Documents

Specification data sheet

Request Product Price

Please select the options you require for the XMD Process Plant DP Cell Differential Pressure Transmitter in your application and request a quote.

"*" indicates required fields