An Isolation diaphragm is a thin membrane which is used to isolate the media on one side of a diaphragm from media on the other side, whilst allowing the transmission of pressure with minimal loss.

An Isolation diaphragm is a thin membrane which is used to isolate the media on one side of a diaphragm from media on the other side, whilst allowing the transmission of pressure with minimal loss.

Isolation diaphragms are also known as diaphragm seals or isolating diaphragm seals.

Isolation diaphragms are incorporated into some core pressure sensor technologies to protect the various components used in the design from exposure to a corrosive pressure media and to provide compatibility with a broader range of liquid and gas types.

Typically the space behind the isolation diaphragm will be filled with a silicone oil which is a good electrical insulator with a low freezing point and vapour pressure.

Where are isolation diaphragms used?

Solid state sensor technology

In terms of modern pressure transducer design, the sensing elements have been developed into much smaller packages with more sophisticated performance. This is particularly true for semiconductor strain gauge sensing diaphragms which include several materials and microscopic electrical contacts in the construction. For most applications that involve humidity or corrosive liquids and gases, the semiconductor sensing element would not last long if exposed to these conditions. However if the semiconductor sensing element is placed inside a capsule with a thin isolation membrane which is filled with a dielectric oil it will be protected from corrosion and electrical damage whilst retaining its high level of performance.

High temperature media

Another use of isolation diaphragms is for adapting a pressure sensing device to an application it was not intended for. The most common applications requiring this modification is use on high temperature media.

If the media is at a higher temperature than what the pressure transducer is rated for, an isolation diaphragm and oil filled seal fitted to the process connection will allow the heat to dissipate thus lowering it to within the pressure transducer specification.

Corrosive media

Add-on isolation diaphragm assemblies are also used to separate highly corrosive media from instrumentation which would otherwise deteriorate or fail when exposed.

Food & drink processing

If the media is food or drink it is not acceptable to use a device filled with a substance that would contaminate the product if the diaphragm failed, and since many oil filled sensors contain a fluid that is a potential contaminant, it is necessary to add-on an isolation diaphragm seal containing a food grade oil.

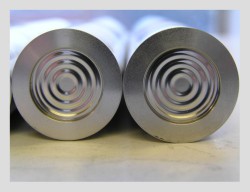

Materials used to make isolation diaphragms

Isolation diaphragms are often made from materials with different corrosion properties such as Stainless Steel 316L, Hastelloy C276, Duplex, Titanium, Tantalum or Monel, expanding the media compatibility of a product.

Glossary of Pressure Sensor technical terms

- Ceramic Pressure Sensors

- Digital Compensation

- Dry Cell

- Dry/Dry

- HART®

- LVDT – Linear Variable Differential Transformer

- Pressure Sensors

- SOI – Silicon on Insulator

- Stainless Steel Pressure Sensors

- Static Line Pressure

- Wet/Dry

- Wet/Wet

Help from Pressure Sensor resources

- Pressure Sensor Accuracy Specifications

- Supply voltage and load resistance considerations for pressure transmitters

- How to Connect a 4-20mA Current Loop Pressure Transmitter

- What is difference between working, burst and over pressure

- What can a DP sensor be used to measure beyond differential pressure?