How do you calculate maximum gauge error in pressure measurement with a bourdon gauge instrument?

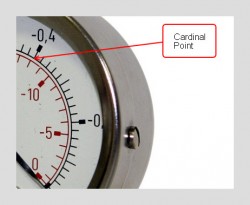

The cardinal point or division markings on the dial face of a Bourdon tube pressure gauge can be separated by a large amount making it difficult to read the pressure precisely and therefore it is not possible to read the error directly when applying an exact calibration pressure setpoint.

The cardinal point or division markings on the dial face of a Bourdon tube pressure gauge can be separated by a large amount making it difficult to read the pressure precisely and therefore it is not possible to read the error directly when applying an exact calibration pressure setpoint.

When calibrating Bourdon tube type or any other type of analogue dial pressure gauge you should adjust the pressure calibrator so that the applied pressure is set to the cardinal point on the pressure gauge. The error can then be read to a much higher precision from the calibrator.

For example a 30 bar gauge with 1 bar incremental marks is calibrated using a 30 bar calibrator with 0.1 bar incremental marks or resolution. To calibrate at the mid point of 15 bar, apply pressure to the gauge until the dial needle is lined up exactly with the 15 bar cardinal point.

Next, note down the pressure on the calibrator, which for this example let’s say is 15.3 bar. If the calibration was performed the other way around you would have to approximate the 0.3 bar error since there is no markers between 14, 15 and 16 bar.

Once you have collected your bourdon tube pressure gauge calibration readings go to the online calculator below to determine the errors in pressure units or as a percentage of full scale.

Related Help Guides

- Simulating 8000 foot altitude with a pressure gauge

- Reduce calibration costs of analogue pressure gauges

- Determine range of pressure gauge needed to measure force generated by hydraulic press