Level sensors for submerging permanently in liquid to determine the level or depth of fluid by measuring the hydrostatic pressure.

Choose a submersible hydrostatic level sensor for use with a liquid such as drinking water, freshwater, seawater, wastewater, chlorinated water, leachate, acids, alkalines.

Hydrostatic liquid level sensors for lowering into a tank, bore hole, river or reservoir.

Select a IP68 waterproof sensor for installing in a underground storage tank, groundwater borehole or in a ships ballast tank.

Products

LMK458 Marine Approved Hydrostatic Level Transmitter - Marine approved level transmitter with 4-20mA output for measuring level of contents inside ship ballast, fuel, liquid cargo or wastewater tanks

LMK458 Marine Approved Hydrostatic Level Transmitter - Marine approved level transmitter with 4-20mA output for measuring level of contents inside ship ballast, fuel, liquid cargo or wastewater tanks LMP307 Submersible Level Transmitter - Submersible level transmitter for measuring liquid level with a 4-20mA current loop or a 0-10V voltage output plus optional ATEX approval for intrinsically safe use in hazardous areas in ranges from 1mH2O up to 250mH2O. The LMP307 is suitable for use on potable water with no leaching, and can be supplied with a drinking water certificate according to DVGW and KTW.

LMP307 Submersible Level Transmitter - Submersible level transmitter for measuring liquid level with a 4-20mA current loop or a 0-10V voltage output plus optional ATEX approval for intrinsically safe use in hazardous areas in ranges from 1mH2O up to 250mH2O. The LMP307 is suitable for use on potable water with no leaching, and can be supplied with a drinking water certificate according to DVGW and KTW.

LMK307 Submersible Waste Water Level Sensor

LMK307 Submersible Waste Water Level Sensor 18.605 G Low Cost Submersible Diesel Fuel and Water Tank Level Sensor

18.605 G Low Cost Submersible Diesel Fuel and Water Tank Level Sensor LMP305 Borehole Level Transmitter

LMP305 Borehole Level Transmitter LMK 858 Plastic Submersible Liquid Level Sensor with Removable Cable

LMK 858 Plastic Submersible Liquid Level Sensor with Removable Cable

Applications

Borewell water level sensor for 100m water height - Low cost solution to measuring the water level in a borewell with a water height of as much as 100 metres above the submerged sensor

Borewell water level sensor for 100m water height - Low cost solution to measuring the water level in a borewell with a water height of as much as 100 metres above the submerged sensor 200m deep well pump water level sensor, switch & display - We need to measure the water level in a well down to 200 meters to protect a well pump by ensuring that it always stays under water

200m deep well pump water level sensor, switch & display - We need to measure the water level in a well down to 200 meters to protect a well pump by ensuring that it always stays under water Contaminated groundwater submersible plastic body 5 psi pressure transducer & display - This submersible pressure transducer and display can be used by landfill site pump techs to read leachate water level above the transducer at the well head.

Contaminated groundwater submersible plastic body 5 psi pressure transducer & display - This submersible pressure transducer and display can be used by landfill site pump techs to read leachate water level above the transducer at the well head. -5…+50degC temperature and 10m range level dual 4-20mA submersible borehole transmitter - A submersible water temperature and level measurement transmitter for submerging in a borehole and measuring temperature over -5 to +50C, and depth down to 10m, from the nose cone, and sending each measurement with a separate 4-20mA signal through the submersible cable electrical connection.

-5…+50degC temperature and 10m range level dual 4-20mA submersible borehole transmitter - A submersible water temperature and level measurement transmitter for submerging in a borehole and measuring temperature over -5 to +50C, and depth down to 10m, from the nose cone, and sending each measurement with a separate 4-20mA signal through the submersible cable electrical connection.

Potable water underground 10ft dia storage tank temperature and level sensor

Potable water underground 10ft dia storage tank temperature and level sensor Lightning protected submersible level sensor for hydroelectric intakes and rivers

Lightning protected submersible level sensor for hydroelectric intakes and rivers 2m range 0.6% conc. chlorine liquid level sensor

2m range 0.6% conc. chlorine liquid level sensor Hot leachate level transmitter for 20m deep well monitoring on landfill sites

Hot leachate level transmitter for 20m deep well monitoring on landfill sites 50m seawater depth and temperature sensor with SDI-12

50m seawater depth and temperature sensor with SDI-12 2 metre deep diesel tank level sensor for submersion

2 metre deep diesel tank level sensor for submersion Submersible oil pressure sensor alternative to Ashdown CNS

Submersible oil pressure sensor alternative to Ashdown CNS 2 meters of freshwater depth, submersible pressure transmitter

2 meters of freshwater depth, submersible pressure transmitter

- Diesel exhaust fluid tank level sensor for fleet storage

- Cement plant process water basin level sensor

- Stilling well 3ft range SDI-12 interface lake water level sensor

- Fleet management system submersible 3000mm height petrol tank level ATEX rated pressure sensor

- Floating dry dock ballast tank 14ft range 4-20mA output submersible seawater level sensor

- Irrigation water channel and storage dam 10m range SDI-12 submersible level sensor

- Filtered rainwater cistern 13ft range 4-20mA submersible drinking and cooking water level sensor

- 120in range 0-5Vdc output submersible river depth sensor

- Drinking water approved 5ft range 4-20mA output submersible reservoir level sensor

- Desalination plant seawater feed tanks 5m range 4-20mA output submersible level sensor

- 10ft range 4-20mA output submersible sea tide depth sensor

- 40m RS485 Modbus RTU submersible borehole pump drawdown depth sensor

Product Help

Securing inside a tank

What is the best way to secure the submersible hydrostatic level sensor inside a tank?

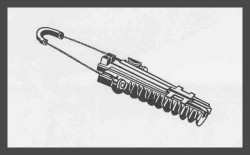

The sensor is often simply dangled into a tank from the top. If the contents of the tank are in motion it is then best to use a perforated stilling tube or a C Clip in the tank to prevent the sensor moving around.

Orientation effects

What is the best orientation for the submersible hydrostatic level sensor?

Most are designed and calibrated to be installed with the end of the probe pointing down, although it is okay to use them in any orientation, as long as you are aware of the effects on calibration. In particular very low pressure ranges are more susceptible to changes in orientation where a thinner diaphragm will move slightly due to its own weight. Also low pressure range devices which are susceptible to trapping air, such as the volume inside a threaded pressure sensor port, will exhibit calibration shifts at different orientations as the quantity of trapped air changes.

Acceptable offset

What is an acceptable offset for submersible level sensors?

The zero & span offset can vary between products of the same type, but they should all fall within an acceptable limit, which is sometimes indicated on the product data sheet, as a +/- small output signal value e.g. +/-0.2mA or a percentage of full scale e.g. < 1% FS.

Some times submersible level sensors can be configured with reverse outputs or large offsets to suit the application, e.g. measuring over a narrow range of level with a large base head of water, or to measure high signal when a well is empty rather than full.

Mounting sensor to measure river or canal depth

What way would you suggest to mount the sensor to be able to measure the depth of a river or a canal?

The sensor can be installed by lowering it slowly into a stilling well. A plastic tube open at both ends and mount to a bridge, jetty or pier is often used to protect the sensor and stop it moving around, whilst still allowing the water to rise and fall with the tides, with an opening at the bottom to ensure the level in the tube equalises with the surrounding water level.

The sensor can be installed by lowering it slowly into a stilling well. A plastic tube open at both ends and mount to a bridge, jetty or pier is often used to protect the sensor and stop it moving around, whilst still allowing the water to rise and fall with the tides, with an opening at the bottom to ensure the level in the tube equalises with the surrounding water level.

The sensor signal cable should be fixed at the top of the tube using a clamp or junction box, so that the sensor position is fixed and cannot move.

Typically the cable will contain a vent tube at the end that is used to allow the sensor reference to vent to atmospheric pressure, which is very important for accurate level measurement.

Typically the cable will contain a vent tube at the end that is used to allow the sensor reference to vent to atmospheric pressure, which is very important for accurate level measurement.

To ensure no moisture does not enters the vent tube it is often fitted with a filter, but it is also important to terminate the cable in a ‘dry’ but vented enclosure such as a purpose built junction box with a built-in air moisture trap or breather filter.

Specifying submersible hydrostatic level sensor and probe requirements

To avoid fitting an unsuitable submersible IP68 pressure sensor for measuring the depth of a liquid, it pays to consider all the factors that will influence the final specification you choose.

If you follow the tips described below you will ensure improved level measurement performance, and a longer service life for the submersible pressure sensor you eventually install.

Liquid type

What type of liquid is to be measured?

This will help select a device with the most compatible construction materials. Submersible pressure sensors are comprised of a sensing module, body, cable and seals, all of which must be compatible with the substance in which the sensor will be immersed.

Density of liquid

What is the specific gravity or density of the liquid compared to freshwater?

The hydrostatic pressure generated by a fixed height of liquid is proportional to the specific gravity. 10 metres of water is a very close approximation to a 1 bar hydrostatic pressure, but if the specific gravity is say 0.9 of water (fresh water has a specific gravity of 1.0) a 10 metre head of this liquid would generate a 0.9 bar hydrostatic pressure instead. The output of some submersible pressure sensors can be scaled to correct for specific gravity without the need for the installer to compensate for it within the signal conditioning instrumentation.

Viscosity of liquid

How viscous is the liquid media?

This will help in determining whether a flush profile is required for the sensing element. High viscosity liquids can choke the protective caps and pressure ports that are fitted to the end of the sensor.

Max/Min level

What is the maximum and minimum level of liquid that will be measured from the intended transducer location?

The total depth of liquid is not necessarily the required hydrostatic range. To improve accuracy of measurement the sensor range should be specified for the change in level. For example a 30 metre deep reservoir may only vary in level by 5 metres throughout the year, so only a 5 metre range is necessary if it is possible to suspend the sensor 5 metres below the maximum water level.

Vented or pressurised liquid

Is the air above the liquid surface open to atmosphere or sealed to a fixed or varying gas pressure?

On occasions it is necessary to cap the top of a well or tank to control the pressure or type of gas present directly above the liquid. In these applications the liquid level reading should be compensated by using an additional pressure sensor to monitor the gas pressure on top of the liquid so it can be subtracted from the level reading to obtain the true reading.

Output signal

What signal output is required by the monitoring instrumentation?

4 to 20mA current loop is the most robust signal and can be used over long distances without degradation from wire losses. O to 10 or 5 volts dc is convenient for use with data acquisition cards and low millivolt signals are best for remote sites with limited battery power. SDI and Modbus are standard digital protocols used mostly by hydrologists for high precision data collection.

Cable length

What is the length of cable required from the deepest transducer position to the termination point?

This may seem like an obvious question, but it is not always possible to terminate the sensor cable at the point where the sensor is suspended from and instead it may need to be connected some distance away from the drop point. When extending a submersible cable it is important to ensure the vented reference is kept dry and open to ambient air pressure. The cable will need to be long enough to reach a dry vented enclosure such as a termination junction box.

Temperature range

What will be the highest and lowest temperature of the liquid?

All submersible sensors have an operating temperature range which should cover the variation on temperatures for most applications. In more extreme environmental conditions or where there are high process generated temperatures, the operating limits of the sensor maybe exceeded. The electronics housing and cable are completely immersed in the liquid and since they tend to be the lowest rated components for temperature, they should be checked for a compatible temperature rating. Although it is less likely to occur there may also be situations where the temperature is too low for the sensor, which may cause damage to the electronics or cable due to thermal contraction or brittleness brought on by the low temperatures.

Diameter limitation

Is there any restriction on the diameter of the transducer that can be used?

For some installations such as hydrological surveys a small diameter borehole is drilled which precludes the use of many submersible pressure sensor probes which are typically more than 1 inch (25.4mm) in diameter. Also since many submersible sensors are relatively long compared to the diameter they can become snagged in the hole if there is not sufficient room to allow free movement when installing the probe. Where the liquid level is very dynamic the sensor can also restrict the rise and fall time of liquid in the borehole if the probe has only a slight clearance tolerance with the borehole.

Hazardous area

Will the transducer be located in an area classed as a hazardous zone?

In Europe many sites such as refineries, waste water treatment plants and landfill sites are required by health and safety authorities to ensure that installations are ATEX approved to reduce risks of explosions from flammable gases.

Lightning protection

Is the region where the installation is going to be located prone to lightning strikes?

Installations outdoors will always be at risk at some time or another from lightning strikes, but some regions are at more risk than others due to regional geography and weather characteristics. In these areas where strikes on instrumentation are numerous, some form of lightning protection maybe necessary to reduce the risk of failures. Although nothing is likely to withstand a direct lightning strike, many failures are caused by voltage surges from local strikes rather than direct hits, so high voltage surge protection circuitry can reduce the likelihood of failure significantly.

Checklist for submersible hydrostatic level sensor and probe requirements

Define your submersible hydrostatic level sensor and probe requirements using this checklist:

- Liquid type?

- Density of liquid?

- Viscosity of liquid?

- Max/Min level?

- Vented or pressurised liquid?

- Output signal?

- Cable length?

- Temperature range?

- Diameter limitation?

- Hazardous area?

- Lightning protection?