A guide to flush diaphragm pressure & level measurement instrumentation, including explanations, applications and a choice of products with flush process fittings.

A guide to flush diaphragm pressure & level measurement instrumentation, including explanations, applications and a choice of products with flush process fittings.

A flush diaphragm is a type of diaphragm which is completely open and exposed to the pressure media and level or slightly recessed to the surrounding surfaces when installed.

A pressure sensing device with a flush diaphragm is installed by either clamping to a flange ring around the outer diameter of the diaphragm or using a thread which has a large enough diameter to incorporate the diaphragm at the tip of the thread.

DS200P Sanitary Low Range Pressure Gauge, Switch and Sensor

DS200P Sanitary Low Range Pressure Gauge, Switch and Sensor LMK307 Submersible Waste Water Level Sensor

LMK307 Submersible Waste Water Level Sensor DMP331P Hygienic Flush Pressure Transmitter

DMP331P Hygienic Flush Pressure Transmitter LMK807 Plastic Submersible Level Transmitter

LMK807 Plastic Submersible Level Transmitter LMK382 Low Range IP68 Waste Water Level Transmitter

LMK382 Low Range IP68 Waste Water Level Transmitter DCL 571 RS485 Modbus RTU Submersible 22mm dia Groundwater & Wastewater Level Probe

DCL 571 RS485 Modbus RTU Submersible 22mm dia Groundwater & Wastewater Level Probe DCL 551 RS485 Modbus RTU Submersible Low Range Fuel, Oil & Wastewater Level Probe

DCL 551 RS485 Modbus RTU Submersible Low Range Fuel, Oil & Wastewater Level Probe LMK387 Cleanable Sewage and Sludge Pressure/Level Sensor

LMK387 Cleanable Sewage and Sludge Pressure/Level Sensor LMK 487 Submersible Ballast Tank and Draught Level Pressure Transmitter

LMK 487 Submersible Ballast Tank and Draught Level Pressure Transmitter DMK331P Flush Diaphragm Pressure Sensor

DMK331P Flush Diaphragm Pressure Sensor LMK809 Plastic Submersible Low Level Transmitter

LMK809 Plastic Submersible Low Level Transmitter LMK351 High Overpressure Flush Level Transmitter

LMK351 High Overpressure Flush Level Transmitter LMK331 Screw-In Ceramic Level Transmitter

LMK331 Screw-In Ceramic Level Transmitter DCT531P RS485 Modbus RTU Flush Pressure Sensor

DCT531P RS485 Modbus RTU Flush Pressure Sensor x|act i Rangeable Flush Pressure Transmitter with LCD Readout

x|act i Rangeable Flush Pressure Transmitter with LCD Readout XMPi Process Plant Gauge and Absolute Pressure Transmitter

XMPi Process Plant Gauge and Absolute Pressure Transmitter Baroli 02P Low Range Flush Diaphragm Digital Pressure Gauge

Baroli 02P Low Range Flush Diaphragm Digital Pressure Gauge TPF Flush Diaphragm Strain Gauge Pressure Sensor

TPF Flush Diaphragm Strain Gauge Pressure Sensor TPFADA Flush Diaphragm Pressure Transmitter

TPFADA Flush Diaphragm Pressure Transmitter 35X Flush Diaphragm Digital Output Pressure Sensor

35X Flush Diaphragm Digital Output Pressure Sensor Baroli 05P High Range Flush Diaphragm Digital Pressure Gauge

Baroli 05P High Range Flush Diaphragm Digital Pressure Gauge DS201P High Range Flush Pressure Gauge, Switch and Sensor

DS201P High Range Flush Pressure Gauge, Switch and Sensor 35X HTC High Temperature Digital Pressure Sensor (< 300 degC)

35X HTC High Temperature Digital Pressure Sensor (< 300 degC) 35X HTT High Temperature Compensated Pressure Sensor

35X HTT High Temperature Compensated Pressure Sensor

Diaphragm Materials & Design

The materials used in the manufacture of flush diaphragms vary with the type of sensor technology and the intended liquid media to be measured. Dry cell sensing elements have typically have thicker and more robust diaphragms which can be used with more abrasive media such as concrete and slurries. Oil-filled sensing elements with thin stainless steel isolation diaphragms can be used in hygienic conditions and on high temperature media.

There are certain media which cannot be used with conventional pressure sensors due to it being either too viscous or requiring a high level of cleanliness.

In some test and research applications a sensor that changes the volume or shape of the vessel / pipe will lead to additional measurement uncertainties.

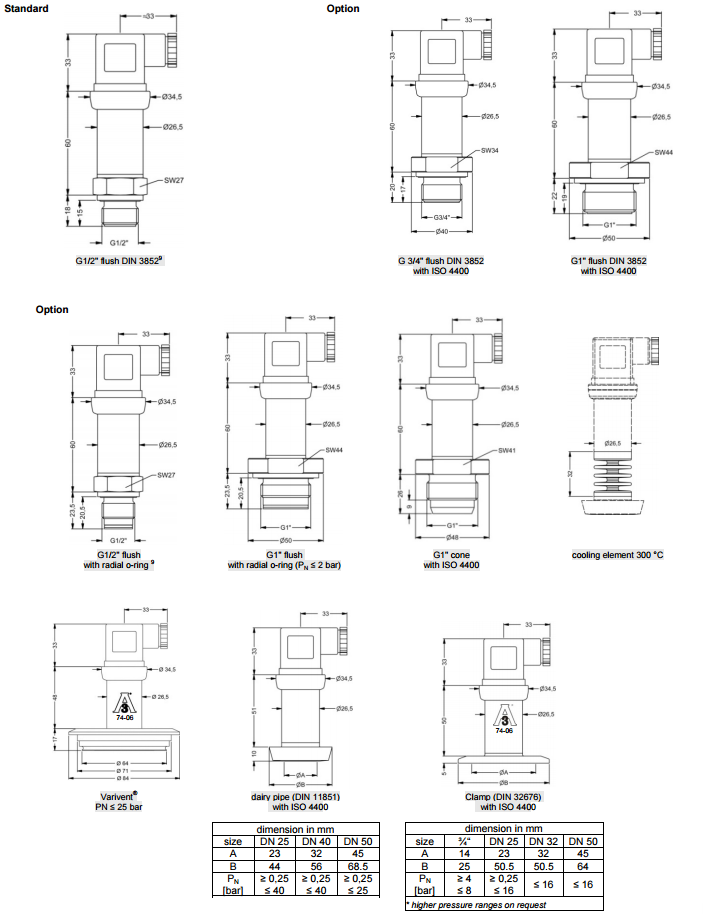

Threaded Style Process Connections

The most common form of flush face pressure sensor has a threaded connection with a completely open diaphragm on the end. Since the pressure connector must accommodate the surface area. of the diaphragm this leads to larger diameter threads such as 1/2 or 1 inch BSP being used in the mechanical design.

Clamped Style Process Connections

The main advantage of the clamped pressure seal over the threaded type is that there is no gap between the thread which would otherwise allow the build up of residues and bacteria. This makes it ideal for food and pharmaceutical production where very high levels of cleanliness are required.

Applications

Flush diaphragms are used in specialised applications where the media is likely to clog enclosed process connections, an increase in volume will interfere with process performance or a high level of hygiene is required. The types of liquid media which require the use of flush diaphragms include sewage, paper pulp, adhesives, paint, food, drinks, pharmaceuticals, medicines, concrete, bitumen and slurries.

High Viscosity Liquids

Substances such as paint, oil, wax, pastes, tar, plastic melt or slurries can potentially block up the process connection of a pressure sensor. The media maybe too stiff to adequately fill the internal void of a pressure connector or the substance might wax once a process has cooled down. For these types of substances it is necessary to specify a flush fitting where the diaphragm is completely open. Where there are concerns about mechanical damage to the diaphragm there are options for recessed flush diaphragms on some pressure sensors.

Pharmaceutical, Food, Beverage & Biotech

For these applications the concern is not necessarily high viscosity but more to do with cleanliness. A flush surface which is fully welded stainless steel 316 and free from crevices is the preferred sensor construction to prevent the build up of process residue, facilitate cleaning and protect against chemical corrosion. For oil filled pressure sensors it is also a requirement to use a fill that is food compatible so that if the diaphragm was to fail without being detected it would not leak any fluid into the process that would be harmful to the consumer.

Waste Water

Exposure to a waste liquid containing solids, sludge and a mixture of chemicals will lead to a highly contaminated pressure sensor. To avoid problems with corrosion and blockage of the sensor, a robust open diaphragm which can withstand the knocks from solid waste and the corrosive effects of chemical interactions is essential. The sensor must also be easy to clean and able to withstand an intensive wash down at regular intervals.

Negligible Volume

In some test and research installations there is the requirement to keep the internal volume or the effect on flow to a minimum. A conventional pressure sensor has an internal volume which may contribute a significant change in the system / test volume. If flow characteristics of a chamber / pipe are critical to measurements, a conventional pressure sensor may interfere with the measurement by changing the flow performance of the apparatus. A flush face device mounted so that the diaphragm is level with the wall of the apparatus will not add any extra volume to the system or interrupt the flow characteristics.