Low cost OEM diesel fuel or water level sensor for installing inside or outside a storage tank. Measure fuel or water level with ranges 0 to 1 metre (3.28 feet) up to 10 metres (32.8 feet). Stainless steel, FKM and PVC construction for compatibility with diesel fuel. Choose between 4-20mA, 0-10Vdc and ratiometric 0.5-4.5Vdc output signals.

Product Parameters

- Hydrostatic Range: 0-1mWC (3.28ftWC) up to 0 – 10mWC (32.8ftWC)

- Output Signals:4-20mA 2 wire or 0-10Vdc 3 wire, 0.5-4.5Vdc ratiometric

- Accuracy: 0.5% full scale

- Electrical Connections: Submersible IP68 sealed gland with PVC coated cable

- Process Connections: G1/4 male with optional nose cone

- Media Compatibility: 304 stainless steel body and process port, 316L stainless steel diaphragm and FKM seal gasket

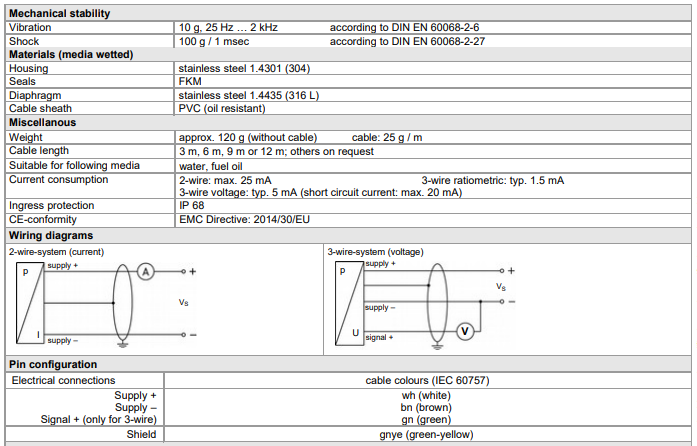

- Dimensions: 24mm diameter

- Weight: 120g approx. plus 25g per metre of cable

Product Description

The 18.605 G is designed specifically for use in water and diesel fuel tank applications to measure the level of liquid and determine the quantity of tank contents. This sensor can be connected to tank gauging instrumentation to provide a local indication of tank level or remote telemetry data of diesel fuel or water usage.

This tank level sensor can be installed by lowering into the inside of a tank or by screwing onto the outside of the tank at the bottom via the G1/4 male (1/4 BSP P male) thread. The electrical connection to the tank level sensor is IP68 rated for continuous submersion in diesel fuel or water.

This tank level sensor can be installed by lowering into the inside of a tank or by screwing onto the outside of the tank at the bottom via the G1/4 male (1/4 BSP P male) thread. The electrical connection to the tank level sensor is IP68 rated for continuous submersion in diesel fuel or water.

There are five standard level ranges available, starting with a 0 to 0.1 bar (1.5 psi) range for small tanks 1 metre (3.28 feet high), 0.25 bar (3.63 psi), 0.4 bar (5.8 psi), 0.6 bar (8.7 psi), and 1 bar (15 psi) range for 10 metre (33 feet) high tanks.

Depending on connected tank content management instrumentation the sensor can be supplied with a low supply voltage which outputs a 10…90% of supply voltage, a 4-20mA current loop which is convenient for connecting most process instrumentation interfaces, and 0-10Vdc output which is commonly used for the analogue input in building management systems.

The housing of the sensor is made from stainless steel 304, the diaphragm is stainless steel 316L, FMK seals are used to provide te IP68 watertight seal at the cable exit, and the cable is jacket is made from PVC which is chemical resistant and compatible with most fuel types.

Product Applications

Diesel main tank level

Use this sensor as part of a remote diesel fuel tank level measurement system with a 4-20mA loop panel display in an outdoor installation where the sensor is lowered into a pipe at the top of the tank using a cord seal.

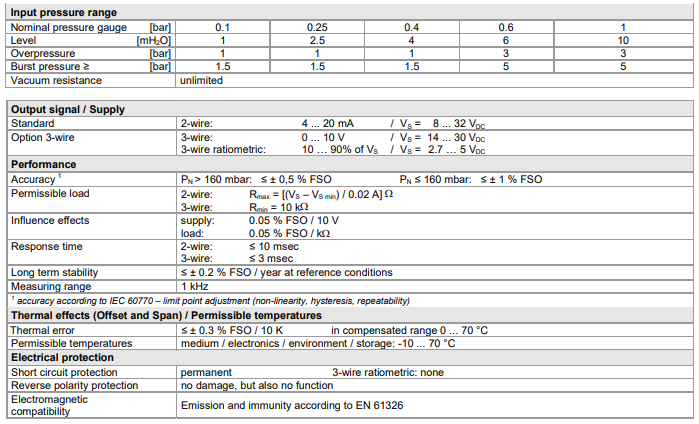

Product Specification

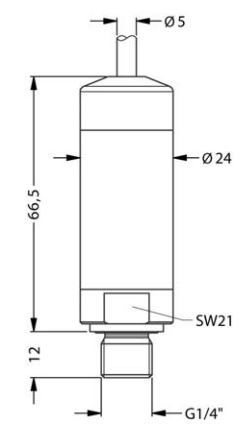

Product Dimensions

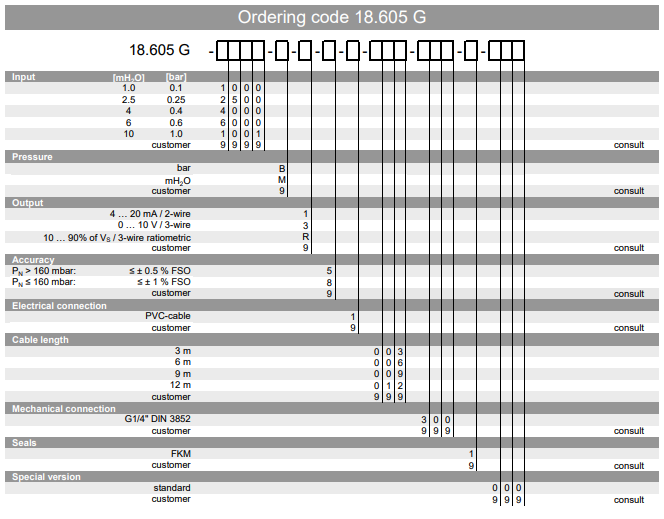

Part Number Configuration

Product Help

Nose cone usage

When would I need to use the nose cone?

Submersible probes are often fitted with a nose cone to protect the sensitive components at the base of the probe. On this device the sensitive component is already protected by the external thread, so it’s not considered to be an essential accessory in that regard, but it will help prevent sediment from collecting inside the threaded port, and reduce the chance of the thread snagging on any obstructions in the bottom of the tank.

Tank sloshing effects on sensor reading

When using this sensor to measure the level of diesel fuel on a train, does the fuel sloshing while a vehicle is in motion affect the sensor’s reading?

It measures pressure of the liquid above the sensor position, so if the liquid is shifting from side to side this will affect the force acting on the bottom of the tank and what the sensor measures. The instrumentation you are connecting to the sensor may include the ability to average the reading over a rolling time period, which can be used to eliminate effects such as sloshing and provide a stable noiseless reading.

Installing vertically or horizontally on tank floor

Does the sensor need to stand vertically or can it be left to rest horizontally on the tank’s floor?

The sensor can measure the level in any orientation, since it is measuring hydrostatic pressure which will be the same in any direction at a particular level in the tank. For very low ranges you may notice a slight change in output depending on orientation, which is due to the g effect on the sensor diaphragm, so if that is the case it is best to calibrate the sensor in the intended orientation it will be installed.

Protecting the sensor port when submerging in tank

The sensor comes with a screw thread and a yellow cover on the sensing end of the device. I see from the instructions that it come with this for screwing into various housings depending upon the application. I was just going to hang the sensor in the tank a few centimetres from the bottom to read the level, do I need to put anything over the threaded opening of the sensor before I put it in the tank?

The yellow cap is a dust cap to prevent any foreign objects entering the pressure port prior to installation, so this should be removed before lowering into the tank.

It will be fine to lower the sensor as you explained, but just to be on the safe side, lower it gently through the surface of the liquid to avoid any pressure shocks, which could damage the diaphragm. Any sudden shocks such as a water hammer or dropping on the floor can damage the sensor because the shock will generate movement in the diaphragm that exceeds it’s pressure rating.

Installing sensor in a vehicle tank

If the tank being measured is on a vehicle, is it adequate to insert it through a top orifice in the tank without having physical access inside to anchor it?

Yes if the sensor is lying on the bottom this can help prevent it moving around, but otherwise you could use a stilling tube of a slightly larger diameter, mounted at the top of the tank, in which you can lower the sensor inside, so that it is protected from movement.

Related Documents

Specification data sheet

Request Product Price

Please select the options you require for the 18.605 G Low Cost Submersible Diesel Fuel and Water Tank Level Sensor in your application and request a quote.