Analog output signal pressure gauges for local indication of pressure and for providing a analog signal input for a PLC or other process control instrumentation.

These pressure gauges combine a LED or LCD digital pressure reading display with a analog output such as 4 to 20mA current loop signal or 0 to 10Vdc voltage signal.

Products

DS200P Sanitary Low Range Pressure Gauge, Switch and Sensor - All in one electronic switch, gauge and sensor designed specifically for use in the food, drink and biomedical industry for measuring process pressures.

DS200P Sanitary Low Range Pressure Gauge, Switch and Sensor - All in one electronic switch, gauge and sensor designed specifically for use in the food, drink and biomedical industry for measuring process pressures. DS210 Combined Low Pressure Switch, Indicator and Sensor - Low range three in one pressure switch, pressure indicator and pressure sensor for use on pneumatics and HVAC applications.

DS210 Combined Low Pressure Switch, Indicator and Sensor - Low range three in one pressure switch, pressure indicator and pressure sensor for use on pneumatics and HVAC applications.

DS200 Combined Pressure Switch, Gauge and Sensor

DS200 Combined Pressure Switch, Gauge and Sensor DS201 Combined Pressure Sensor, Display and Switch

DS201 Combined Pressure Sensor, Display and Switch LEO3 Current or Digital Output Pressure Gauge

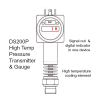

LEO3 Current or Digital Output Pressure Gauge DS201P High Range Flush Pressure Gauge, Switch and Sensor

DS201P High Range Flush Pressure Gauge, Switch and Sensor

Applications

Injection moulding machine 22000 psig 4-20mA output synthetic hydraulic oil pressure sensor - A digital display and high pressure sensor for injection moulding machine use to measure pressure of synthetic hydraulic oil over a range of 0 to 22,000 psi g from the 9/16 UNF female process connection, and sending the corresponding 4-20mA signal through the M12 connector electrical connection.

Injection moulding machine 22000 psig 4-20mA output synthetic hydraulic oil pressure sensor - A digital display and high pressure sensor for injection moulding machine use to measure pressure of synthetic hydraulic oil over a range of 0 to 22,000 psi g from the 9/16 UNF female process connection, and sending the corresponding 4-20mA signal through the M12 connector electrical connection. 0 to 9 pascals range pressure gauge - Low Pascal range pressure gauge for measuring from 0 to 9 pascals and provide a digital readout of the pressure readings?

0 to 9 pascals range pressure gauge - Low Pascal range pressure gauge for measuring from 0 to 9 pascals and provide a digital readout of the pressure readings? 250psig hi-temp hydraulic oil digital pressure gauge and 4-20mA output - Digital pressure gauge with 4 to 20 mA output for pipe mounted use in synthetic hydraulic oil measurement applications, capable of measuring 0 to 250 psi g pressure with 1% accuracy and connected using a G1/2 male fitting.

250psig hi-temp hydraulic oil digital pressure gauge and 4-20mA output - Digital pressure gauge with 4 to 20 mA output for pipe mounted use in synthetic hydraulic oil measurement applications, capable of measuring 0 to 250 psi g pressure with 1% accuracy and connected using a G1/2 male fitting. 600 barg freshwater booster pump pressure switch, gauge and transmitter - Digital display pressure switch, gauge and transmitter for pipe mounted use in freshwater booster pump measurement applications, capable of measuring 0 to 600 bar g pressure with 0.35% accuracy and connected using a 1/4 BSP P male fitting.

600 barg freshwater booster pump pressure switch, gauge and transmitter - Digital display pressure switch, gauge and transmitter for pipe mounted use in freshwater booster pump measurement applications, capable of measuring 0 to 600 bar g pressure with 0.35% accuracy and connected using a 1/4 BSP P male fitting.

20 MPa g range 4-20mA output high pressure sensor and plug-on display for hydraulic control use

20 MPa g range 4-20mA output high pressure sensor and plug-on display for hydraulic control use -15psig 0-10V out negative pressure transducer and display for air extraction use

-15psig 0-10V out negative pressure transducer and display for air extraction use 10 barg food and beverage pressure gauge with 4-20mA output

10 barg food and beverage pressure gauge with 4-20mA output -0.1 to +0.1 inH2O g range 4-20mA signal air pressure sensor and display for pharmaceutical manufacturing use

-0.1 to +0.1 inH2O g range 4-20mA signal air pressure sensor and display for pharmaceutical manufacturing use 1 inH2O dp range wall mounted HEPA air filter pressure gauge with 4-20mA output

1 inH2O dp range wall mounted HEPA air filter pressure gauge with 4-20mA output 3000 psig range 0-10Vdc output digital display pressure transducer for hydraulic control use

3000 psig range 0-10Vdc output digital display pressure transducer for hydraulic control use 100 psig range landfill leachate pressure gauge with 4-20mA output for SCADA sytem

100 psig range landfill leachate pressure gauge with 4-20mA output for SCADA sytem 5psig 0-10V out freshwater pressure transducer and built-in display for water purifier use

5psig 0-10V out freshwater pressure transducer and built-in display for water purifier use

- 250psig air regulator pressure gauge with 4-20mA output and 1/4 NPT male fitting

- 60psig range pharmaceutical pressure gauge and 0-10Vdc transducer with triclamp fitting

- 20 mbarg digital display air pressure indicator and transmitter with 1/4 NPT male fitting

- 3inH2O differential 4-20mA nitrogen pressure sensor and display for annealing furnace flow control use

- 500psig 4-20mA freshwater display, switch and pressure sensor for building management use

- 20 kPa negative differential range air pressure gauge and sensor with tubing fitting

- Refrigerant coolant 500mbarg pressure gauge with all welded G1/2 male fitting and 4-20mA output

- 50 psig range hydrocarbon gases pressure gauge with 1/2 NPT male fitting

- Low vacuum leak detection 4-20mA current loop sensor & gauge

- 16 bar, 200°C steam pressure transmitter and gauge

- Hastelloy diaphragm -100 to 50 kPa g range manometer

- Autoclave pressure sensor and display with 10 bar range

Product Types

Pressure Indicator Transmitters - Pressure indicator transmitters have a digital indicator for providing a local pressure reading, and a 4-20mA pressure transmitter.

Pressure Indicator Transmitters - Pressure indicator transmitters have a digital indicator for providing a local pressure reading, and a 4-20mA pressure transmitter.