Pressure indicator transmitters have a digital indicator for providing a local indication of pressure reading, and a 4-20 milliamp output pressure transmitter for sending an analogue signal to control & monitoring instrumentation.

The built-in digital indicators can be scaled via push buttons or adjustment pots to any pressure unit or a 0-100% full scaling.

No additional external supply is required, since the digital indicator is powered by the 4-20mA current loop from the pressure transmitter.

Products

DS200P Sanitary Low Range Pressure Gauge, Switch and Sensor - All in one electronic switch, gauge and sensor designed specifically for use in the food, drink and biomedical industry for measuring process pressures.

DS200P Sanitary Low Range Pressure Gauge, Switch and Sensor - All in one electronic switch, gauge and sensor designed specifically for use in the food, drink and biomedical industry for measuring process pressures. DS210 Combined Low Pressure Switch, Indicator and Sensor - Low range three in one pressure switch, pressure indicator and pressure sensor for use on pneumatics and HVAC applications.

DS210 Combined Low Pressure Switch, Indicator and Sensor - Low range three in one pressure switch, pressure indicator and pressure sensor for use on pneumatics and HVAC applications.

DS200 Combined Pressure Switch, Gauge and Sensor

DS200 Combined Pressure Switch, Gauge and Sensor DS201 Combined Pressure Sensor, Display and Switch

DS201 Combined Pressure Sensor, Display and Switch LEO3 Current or Digital Output Pressure Gauge

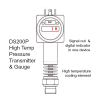

LEO3 Current or Digital Output Pressure Gauge DS201P High Range Flush Pressure Gauge, Switch and Sensor

DS201P High Range Flush Pressure Gauge, Switch and Sensor

Applications

Injection moulding machine 22000 psig 4-20mA output synthetic hydraulic oil pressure sensor - A digital display and high pressure sensor for injection moulding machine use to measure pressure of synthetic hydraulic oil over a range of 0 to 22,000 psi g from the 9/16 UNF female process connection, and sending the corresponding 4-20mA signal through the M12 connector electrical connection.

Injection moulding machine 22000 psig 4-20mA output synthetic hydraulic oil pressure sensor - A digital display and high pressure sensor for injection moulding machine use to measure pressure of synthetic hydraulic oil over a range of 0 to 22,000 psi g from the 9/16 UNF female process connection, and sending the corresponding 4-20mA signal through the M12 connector electrical connection. 600 barg freshwater booster pump pressure switch, gauge and transmitter - Digital display pressure switch, gauge and transmitter for pipe mounted use in freshwater booster pump measurement applications, capable of measuring 0 to 600 bar g pressure with 0.35% accuracy and connected using a 1/4 BSP P male fitting.

600 barg freshwater booster pump pressure switch, gauge and transmitter - Digital display pressure switch, gauge and transmitter for pipe mounted use in freshwater booster pump measurement applications, capable of measuring 0 to 600 bar g pressure with 0.35% accuracy and connected using a 1/4 BSP P male fitting. 20 MPa g range 4-20mA output high pressure sensor and plug-on display for hydraulic control use - A high pressure sensor and plug-on display for hydraulic control use to measure pressure of mineral hydraulic oil over a range of 0 to 20 MPa g from the G1/8 male process connection, and sending the corresponding 4-20mA current loop signal through the DIN plug connector electrical connection.

20 MPa g range 4-20mA output high pressure sensor and plug-on display for hydraulic control use - A high pressure sensor and plug-on display for hydraulic control use to measure pressure of mineral hydraulic oil over a range of 0 to 20 MPa g from the G1/8 male process connection, and sending the corresponding 4-20mA current loop signal through the DIN plug connector electrical connection. -15psig 0-10V out negative pressure transducer and display for air extraction use - A digital display pressure transducer for air extraction use to measure negative pressure difference of air inlet over a range of 0 to -15 psi g from a 1/4 NPT male process connection, and sending the corresponding 0-10Vdc signal through the DIN plug electrical connection.

-15psig 0-10V out negative pressure transducer and display for air extraction use - A digital display pressure transducer for air extraction use to measure negative pressure difference of air inlet over a range of 0 to -15 psi g from a 1/4 NPT male process connection, and sending the corresponding 0-10Vdc signal through the DIN plug electrical connection.

-0.1 to +0.1 inH2O g range 4-20mA signal air pressure sensor and display for pharmaceutical manufacturing use

-0.1 to +0.1 inH2O g range 4-20mA signal air pressure sensor and display for pharmaceutical manufacturing use 250psig air regulator pressure gauge with 4-20mA output and 1/4 NPT male fitting

250psig air regulator pressure gauge with 4-20mA output and 1/4 NPT male fitting 20 mbarg digital display air pressure indicator and transmitter with 1/4 NPT male fitting

20 mbarg digital display air pressure indicator and transmitter with 1/4 NPT male fitting 3inH2O differential 4-20mA nitrogen pressure sensor and display for annealing furnace flow control use

3inH2O differential 4-20mA nitrogen pressure sensor and display for annealing furnace flow control use 500psig 4-20mA freshwater display, switch and pressure sensor for building management use

500psig 4-20mA freshwater display, switch and pressure sensor for building management use Low vacuum leak detection 4-20mA current loop sensor & gauge

Low vacuum leak detection 4-20mA current loop sensor & gauge 16 bar, 200°C steam pressure transmitter and gauge

16 bar, 200°C steam pressure transmitter and gauge Hastelloy diaphragm -100 to 50 kPa g range manometer

Hastelloy diaphragm -100 to 50 kPa g range manometer

- Autoclave pressure sensor and display with 10 bar range

- 10 bar g steam pressure transmitter and indicator

- 10 metre high cylindrical oil tank level gauge and transmitter

- Combined readout and transmitter for measuring up to 250 bar Methane gas

- Hot oil pressure transmitter & display to read up to 5 bar at 300degC max

- 3in1 ATEX 10bar pump pressure transducer, gauge & switch

- Truck loading monitoring using air cushion pressure

- Read, transmit and trip Methane gas pressure between 0-160mb g in one device

Product Help

Specifying pressure indicator transmitter features

Indicator type

A pressure indicator transmitter includes a built-in pressure gauge for reading in-situ.

Do you require LCD, backlit LCD, or an LED display?

A display can be configured to display the pressure reading in different pressure units, or as a % full scale, the 4-20mA output, alarm levels, and calibration values.

Output signal

Typically a pressure transmitter with a built-in display indicator will have a 4-20mA 2 wire current loop signal. This 4-20mA signal may include intrinsically safe or flameproof certification for hazardous areas, and HART communications for use in a process plant with other HART enabled devices.

Alarm switch

Since there is a built-in display it is possible to add alarm contact switches on some pressure indicator transmitters which are easily configurable via the display and menu keys.

The contact switches are normally a solid state type such as PNP or NPN, which keeps the size and wiring to a minimum.

Re-calibration

Depending on the product type it is possible to re-calibrate the 4-20mA output signal and the display reading by adjusting the zero and span setting via the display panel menu buttons.

Turn-down ratio

Turn-down the output signal to re-scale the measured range. The turndown ratio defines how low the range can be reduced. A ratio of 3:1 or 4:1 is possible with simpler lower cost transmitters, and increases to 10:1 or 100:1 with more expensive intelligent transmitters.

Will the pressure indicating transmitter need to be moved or re-purposed to measure over a different range?

Checklist for pressure indicator transmitter requirements

Define your pressure indicator transmitter requirements using this checklist:

- Indicator type?

- Output signal?

- Alarm switch?

- Re-calibration?

- Turn-down ratio?

- Pressure range?

- Electrical connection?

- Process connection?