How do you calculate maximum gauge error in pressure measurement with a bourdon gauge instrument?

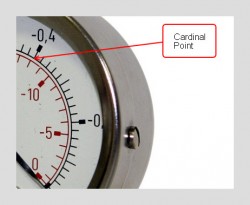

The cardinal point or division markings on the dial face of a Bourdon tube pressure gauge can be separated by a large amount making it difficult to read the pressure precisely and therefore it is not possible to read the error directly when applying an exact calibration pressure setpoint.

When calibrating Bourdon tube type or any other type of analogue dial pressure gauge you should adjust the pressure calibrator so that the applied pressure is set to the cardinal point on the pressure gauge. The error can then be read to a much higher precision from the calibrator.

Featured pressure gauge products

16 bar, 200°C steam pressure transmitter and gauge - Combined pressure transmitter and indicator in one package with the option for use with high temperature media such as steam at 200°C

16 bar, 200°C steam pressure transmitter and gauge - Combined pressure transmitter and indicator in one package with the option for use with high temperature media such as steam at 200°C Pressure Indicator Transmitters - Pressure indicator transmitters have a digital indicator for providing a local pressure reading, and a 4-20mA pressure transmitter.

Pressure Indicator Transmitters - Pressure indicator transmitters have a digital indicator for providing a local pressure reading, and a 4-20mA pressure transmitter.

For example a 30 bar gauge with 1 bar incremental marks is calibrated using a 30 bar calibrator with 0.1 bar incremental marks or resolution. To calibrate at the mid point of 15 bar, apply pressure to the gauge until the dial needle is lined up exactly with the 15 bar cardinal point.

Next, note down the pressure on the calibrator, which for this example let’s say is 15.3 bar. If the calibration was performed the other way around you would have to approximate the 0.3 bar error since there is no markers between 14, 15 and 16 bar.

Once you have collected your bourdon tube pressure gauge calibration readings go to the online calculator below to determine the errors in pressure units or as a percentage of full scale.

Featured pressure gauge products

DS200P Sanitary Low Range Pressure Gauge, Switch and Sensor - All in one electronic switch, gauge and sensor designed specifically for use in the food, drink and biomedical industry for measuring process pressures.

DS200P Sanitary Low Range Pressure Gauge, Switch and Sensor - All in one electronic switch, gauge and sensor designed specifically for use in the food, drink and biomedical industry for measuring process pressures. Clean room monitoring system to measure pressure, humidity & temperature in 4 individual rooms - A complete clean room measurement system for 4 separate rooms, each with its own room pressure, humidity and air temperature indicator, and a central monitoring unit for clean room corridor or control room.

Clean room monitoring system to measure pressure, humidity & temperature in 4 individual rooms - A complete clean room measurement system for 4 separate rooms, each with its own room pressure, humidity and air temperature indicator, and a central monitoring unit for clean room corridor or control room.

Related Help Guides

- Determine range of pressure gauge needed to measure force generated by hydraulic press

- Simulating 8000 foot altitude with a pressure gauge

- Reduce calibration costs of analogue pressure gauges

Related Technical Terms

Related Product and Application Guides

Related Application Questions and Answers

- 16 bar, 200°C steam pressure transmitter and gauge

- 60000 psi pressure indicator with RS232 interface

- Calibrate air pressure gauges ranging to 60psi with NPT fittings

- Pressure gauge for recording pressure 0-6 bar on PC/Laptop

- 1MPa, 10bar, 4000inH2O, 150psi, 1000kPa range pressure gauge

- Data acquisition module 0-10Vdc output pressure gauge

- Salt water pump pressure sensor & gauge with 250 psi range

- Above ground level potable water tank pressure level indicator

- Burst pressure chamber gauge with 10 barg range and saved maximum reading

- Rupture disc maximum pressure test gauge

- 270 degC gas pressure indicator

- Measuring force of a hydraulic press using a pressure gauge

Contact us about this Determining calibration error of Bourdon tube pressure gauge page to request more information, or to discuss your application requirements.