High temperature pressure transmitters with a 4-20mA output, tolerant to high temperature applications such as steam, food processing & engine monitoring.

High temperature pressure transmitters are used in applications where the media temperature exceeds the temperature limits of standard pressure transmitters or where it is not possible to fit a stand off pipe, pigtail or other cooling device to reduce the media temperature.

Products

DS200P Sanitary Low Range Pressure Gauge, Switch and Sensor - All in one electronic switch, gauge and sensor designed specifically for use in the food, drink and biomedical industry for measuring process pressures.

DS200P Sanitary Low Range Pressure Gauge, Switch and Sensor - All in one electronic switch, gauge and sensor designed specifically for use in the food, drink and biomedical industry for measuring process pressures. IMPLR Low Range All Stainless Steel OEM Pressure Sensor - Low cost sensor for measuring small pressure ranges from 0-50 mbar (10 inH2O) to 0-1000 mbar (15 psi) of liquids or gases.

IMPLR Low Range All Stainless Steel OEM Pressure Sensor - Low cost sensor for measuring small pressure ranges from 0-50 mbar (10 inH2O) to 0-1000 mbar (15 psi) of liquids or gases.

DMP331P Hygienic Flush Pressure Transmitter

DMP331P Hygienic Flush Pressure Transmitter ATM/T Pressure and Temperature Dual Output Transmitter

ATM/T Pressure and Temperature Dual Output Transmitter IMP Low Cost Pressure Sensor

IMP Low Cost Pressure Sensor DMK331P Flush Diaphragm Pressure Sensor

DMK331P Flush Diaphragm Pressure Sensor

Applications

300 F protected 100 psi pressure transmitter - The IMP is a low cost pressure transmitter which has the option for a built-in process connector extender designed to reduce the temperature.

300 F protected 100 psi pressure transmitter - The IMP is a low cost pressure transmitter which has the option for a built-in process connector extender designed to reduce the temperature. Diaphragm sealed high temperature pressure transmitter for -1 to 25 kg/cm² - Diaphragm sealed pressure transmitter for measuring over -1 to 25 kg/cm² on liquid with a flush type diaphragm up to a temperature of 190°C.

Diaphragm sealed high temperature pressure transmitter for -1 to 25 kg/cm² - Diaphragm sealed pressure transmitter for measuring over -1 to 25 kg/cm² on liquid with a flush type diaphragm up to a temperature of 190°C. Alternative 200 bar melt pressure transmitter with T/C - The current installed sensor has a 200bar pressure, 20mA full scale output, 1/2" 20UNF-2A thread

Alternative 200 bar melt pressure transmitter with T/C - The current installed sensor has a 200bar pressure, 20mA full scale output, 1/2" 20UNF-2A thread Minus 30 inHg 4-20mA air pressure sensor for measuring vacuum in a sealed tank heated to 350F - A hi-temp media 200°C/392°F max gauge pressure sensor for measuring vacuum in a sealed tank heated to 350 degrees F over a range of 0 to -30 inHg g from the G1/2 male process connection, and sending the corresponding 4-20mA signal through the field housing electrical connection.

Minus 30 inHg 4-20mA air pressure sensor for measuring vacuum in a sealed tank heated to 350F - A hi-temp media 200°C/392°F max gauge pressure sensor for measuring vacuum in a sealed tank heated to 350 degrees F over a range of 0 to -30 inHg g from the G1/2 male process connection, and sending the corresponding 4-20mA signal through the field housing electrical connection.

20 barg 4-20mA output 200degC steam pressure sensor for process control use

20 barg 4-20mA output 200degC steam pressure sensor for process control use 5 barg 4-20mA output pressure sensor for steam sterilization up to 150C/300F

5 barg 4-20mA output pressure sensor for steam sterilization up to 150C/300F 10psig 4-20mA oily wastewater pressure sensor with hi-temp protection for tank level gauging use

10psig 4-20mA oily wastewater pressure sensor with hi-temp protection for tank level gauging use High temperature 4.0 bar absolute range 4-20mA output steam pressure sensor for sterilizing use

High temperature 4.0 bar absolute range 4-20mA output steam pressure sensor for sterilizing use 150psig range 4-20mA high temperature pressure sensor for steam generator system use

150psig range 4-20mA high temperature pressure sensor for steam generator system use 10 bar absolute 4-20mA natural gas pressure sensor for high temperature research use

10 bar absolute 4-20mA natural gas pressure sensor for high temperature research use 800mbar absolute range 4-20mA output high temperature protected OEM pressure sensor

800mbar absolute range 4-20mA output high temperature protected OEM pressure sensor 6 bar absolute range 4-20mA output high temperature epoxy resin pressure sensor for research use

6 bar absolute range 4-20mA output high temperature epoxy resin pressure sensor for research use

- 10 barg range 4-20mA output steam pressure sensor for food processing use

- 20 barg range 4-20mA output 300degC hi-temp air pressure sensor for aerospace testing use

- 10 bar g steam pressure transmitter

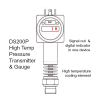

- 16 bar, 200°C steam pressure transmitter and gauge

- 300°C max temperature, 0 to 300 bar, high range pressure sensor

- Measuring steam pressure up to 10bar with analog/digital output

- 300 degC tolerant pressure transmitter for pressures up to 100 kPa g

- Autoclave pressure sensor and display with 10 bar range

- 320 degF steam temperature, 100 psi pressure transmitter

- 25 kg/cm2 high temperature steam pressure transmitter

- 180°C UHT milk compatible pressure transmitter

- Saturated steam pressure transmitter for 185psi max pressure & 392F max temp

Product Help

Specifying pressure transmitters for high temperature use

Process temperature

What will be the maximum process temperature reached in your application?

The sensor technology utilised in pressure transmitter has an operating temperature range which is adequate for most applications, but there are some which will require additional components to protect the sensor from heat damage.

Cooling mechanism

Typically the design approach is to reduce the temperature in the vicinity of the pressure transmitter by incorporating a mechanical cooling assembly to dissipate the heat.

The cooling assembly maybe filled with oil and separated from the process media by an isolation diaphragm.

Alternatively the cooling assembly can include hollow tubing shaped to increase heat transfer, which causes the process media allowed through, to reduce to a much lower temperature.

The choices of cooling mechanism fall into the following categories:

Add-on cooling adaptor

Add-on compact process media filled cooling adaptor with coiled capillary, hollow discs or fins for increasing surface area to act as heat sink for medium temperature protection.

Integral cooling element

Integral oil-filled isolation diaphragm seal shaped to increase surface area between sensor and isolation diaphragm to increase efficiency of cooling and provide for high temperature protection.

Capillary tube cooling

Integral oil, mercury or other fluid filled capillary with a long length and small diameter for extra cooling in very high temperature processes.

Ambient temperature

What will be the range of temperatures surrounding the pressure transmitter where it is installed?

This is an important consideration when dealing with high temperature processes or surrounding environments.

In applications where the process temperature is high, it is possible to use a pressure transmitter with a built-in cooling mechanism. This cooling mechanism often relies on the conduction and dissipation of heat to the surrounding air around the pressure transmitter. Therefore it is essential the ambient air temperature is lower than the process temperature. Also since the rest of the pressure transmitter connected to the cooling component is not protected from high temperatures, the ambient temperature should be lower than the device operating temperature range. This will ensure an efficient heat sink and protect the electronic components from thermal damage.

When it is not possible to install the pressure transmitter in a lower temperature environment, it is then necessary to use one that is completely protected from high ambient or process temperatures. These types of high temperature pressure transmitters do not need any cooling mechanism, and all components including the sensing technology, conditioning electronics, solder, adhesives, connectors and cables are rated to the maximum operating temperature.

Checklist for high temperature pressure transmitter requirements

Define your high temperature pressure transmitter requirements using this checklist:

- Process temperature?

- Cooling mechanism?

- Ambient temperature?

- Pressure range?

- Output signal? 4-20mA

- Electrical connection?

- Process connection?

- Process media type?