Versatile low price pressure transducer with a wide selection of electrical and mechanical options to enable the customisation of the sensor to suit most industrial, automation and OEM design installations.

Product Parameters

- Pressure Ranges: 1000 mbar (15psi) up to 700 bar (10,000psi) gauge or absolute plus suction and compound ranges

- Accuracy: 0.25% or 0.1% FS BSL

- Output Signals: 4-20mA, 0/1-5Vdc, 0/1-10Vdc, 0/1-6Vdc, 0.5-4.5Vdc, 2mV/V or 10mV/V (amplified ratiometric) sensitivity

- Electrical Connections: IP66 Integral cable gland, DIN plug, Military Amphenol,Binder and M12 connectors

- Pressure Connections: 1/8, 1/4, 1/2 BSP, 1/8, 1/4, 1/2 NPT, 7/16, 9/16 UNF and M20 threads male and female

- Special Options: 150 DegC cooling element, 0.1% FS accuracy

- Media Compatibility: 303 stainless steel, Ceramic Al2O3 diaphragm and Viton/NBR/EPDM seal gasket

- Dimensions: 27mm diameter

- Weight: 100g

Product Description

The IMP pressure sensor has a 303 stainless steel body housing and pressure connector as standard. For more corrosive applications it is possible to supply with a 316 or a Duplex stainless steel pressure connector. For large quantity OEM applications a plastic construction is also an option for non-metal compatible media.

A dry cell ceramic strain gauge sensing diaphragm provides a high corrosion resistance to many types of harsh chemical media commonly found in automated industrial processes and machinery monitoring applications.

Any factory set pressure scaling between -1 and 700 bar is possible with the IMP digital signal conditioning electronics, just specify what you require in the comments below before submitting the form. Depending on the quantity required, it is also possible to consider custom electrical and process connectors to suit your application.

Applications

Marine hydraulic reel

Sensing the load on a hydraulic reel in marine applications.

- SKU ID: s1-imp-0014

- Part No: IMP-GP1K5-6A4-BAV-00-000

- Pressure Range: 0-1500

- Units: psi

- Range Type: Positive Gauge (atm to +P)

- Output Signal: 0 – 5V, 3-wire (6)

- Non-Linearity and Hysteresis: 0.25% FS (standard) (A)

- Thermal Zero Shift: 0.04% FS per °C (standard) (4)

- Electrical Connection: Large DIN plug (standard) (B)

- Process Connection: G1/4 male DIN 3852 (A)

- Media Exposed Seals: Viton (standard)(V)

- Special Requirements: Standard (000)

Oxygen tank

Monitor the pressure of Oxygen gas in pressurised tank using the Oxygen clean version of the IMP pressure sensor.

- SKU ID: s1-imp-0013

- Part No: IMP-G2003-9A4-BAV-00-006

- Pressure Range: 0 to 200

- Units: bar

- Range Type: Positive Gauge (atm to +P)

- Output Signal: 0.5 – 4.5V, 3-wire ratiometric (9)

- Non-Linearity and Hysteresis: 0.25% FS (standard) (A)

- Thermal Zero Shift: 0.04% FS per °C (standard) (4)

- Electrical Connection: Large DIN plug (standard) (B)

- Process Connection: G1/4 male DIN 3852 (A)

- Media Exposed Seals: Viton (V)

- Special Requirements: Oxygen cleaned (006)

Steam boiler

Monitor steam boiler pressure up to 5 bar absolute with a temperature range up to 150°C.

- SKU ID: s1-imp-0012

- Part No: IMP-A5000-5A4-BQV-00-000

- Pressure Range: 5

- Units: bar

- Range Type: Absolute (0 to +P)

- Output Signal: 4 – 20mA, 2-wire (5)

- Non-Linearity and Hysteresis: 0.25% FS (standard) (A)

- Thermal Zero Shift: 0.04% FS per °C (standard) (4)

- Electrical Connection: Large DIN plug (standard) (B)

- Process Connection: G1/2 male, 150°C Integrated cooler (Q)

- Media Exposed Seals: Viton (standard)(V)

- Special Requirements: Standard (000)

Robotics compressor tanks

Monitor the air pressure inside compressor storage tanks which provide the air supply to power robotic pneumatic controls.

- SKU ID: s1-imp-0011

- Part No: IMP-GP120-6A4-AAV-00-000

- Pressure Range: 120psi

- Units: psi

- Range Type: Positive Gauge (atm to +P)

- Output Signal: 0 – 5V, 3-wire (6)

- Non-Linearity and Hysteresis: 0.25% FS (standard) (A)

- Thermal Zero Shift: 0.04% FS per °C (standard) (4)

- Electrical Connection: Small DIN plug (A)

- Process Connection: G1/4 male DIN 3852 (A)

- Media Exposed Seals: Viton (standard)(V)

- Special Requirements: Standard (000)

High pressure furnace

Measuring incoming Nitrogen line on a high pressure furnace.

- SKU ID: s1-imp-0003

- Pressure Range: 0 to 25

- Units: bar

- Range Type: Positive Gauge (atm to +P)

- Output Signal: 4 – 20mA, 2-wire (5)

- Non-Linearity and Hysteresis: 0.25% FS (standard) (A)

- Thermal Zero Shift: 0.04% FS per °C (standard) (4)

- Electrical Connection: Large DIN plug (standard) (B)

- Process Connection: G1/2 male DIN 3852 (F)

- Media Exposed Seals: Viton (standard)(V)

- Special Requirements: Standard (000)

Airscrew compressor inlet

Air inlet sensor for air screw compressor.

- SKU ID: s1-imp-0010

- Part No: IMP-A1100-6A4-BRV-00-000

- Pressure Range: 0 to 1100

- Units: mbar

- Range Type: Absolute (0 to +P)

- Output Signal: 0 – 5V, 3-wire (6)

- Non-Linearity and Hysteresis: 0.25% FS (standard) (A)

- Thermal Zero Shift: 0.04% FS per °C (standard) (4)

- Electrical Connection: Large DIN plug (standard) (B)

- Process Connection: 1/4 NPT male, 150°C Integrated cooler (R)

- Media Exposed Seals: Viton (standard)(V)

- Special Requirements: Standard (000)

Engine vacuum

Vacuum transducer for measuring engine vacuum.

- SKU ID: s1-imp-0017

- Datum: Gauge (G)

- Pressure Range: 0 to -15 psi

- Output: 1 – 5V, 3-wire (8)

- Non-Linearity and Hysteresis: 0.25% FS (standard) (A)

- Thermal Zero Shift: 0.04% FS per °C (standard) (4)

- Electrical Connection: Large DIN plug (B)

- Process Connection: G1/4 male, 150°C Integrated cooler (P)

- Internal Seal Material: Viton (standard)(V)

- Cable Length if required (metres):

- Special Requirements: Standard (000)

Product Help

Sensor Technology

Transducer type

What transducer technology is used inside the IMP, is it thin film strain gauge, capacitance, resonant wire or inductive?

The sensor technology used inside the IMP pressure transmitter is a thick film strain gauge which is printed onto a ceramic substrate which acts as the sensing diaphragm.

Electrical Characteristics

How to connect Earth pin

I have a IMP with a 0-5 volt output and large DIN plug configuration, inside the plug there is an Earth pin connection, should it be connected, along with Pin 2 (-ve supply), to the battery negative, or should it be connected to the casing of the instrument?

This Earth pin is used for screening to reduce electrical noise.

If the cable you are wiring into the DIN plug has a screen, then connect that to the Earth pin, otherwises there is no need to connect it. The Earth pin allows you to the connect the sensor housing to the cable screen if required.

- Pin 1 > + supply

- Pin 2 > – supply / – output

- Pin 3 > + output

- Earth pin (internallly wired to case) > optional: connect to cable screen or leave unconnected

It depends on your ground/screen wiring at either end whether or not you connect the Earth pin to the cable screen:

- If the screen is connected to ground at the other end of the cable, and the process connection is grounded then there is no need to connect the Earth pin to the screen. If it is connected it may create Earth loops which might interfere with the sensor due to varying Earth potentials.

- If the screen is connected to ground at the other end of the cable, and the process connection is electrically isolated then you should be able to connect the Earth pin.

- If the screen is not connected to ground at the other end of the cable, and the process connection is grounded then you will need to connect the Earth pin to the screen, otherwise the cable maybe susceptible to picking up external interference.

- If the screen is not connected to ground at the other end of the cable, and the process connection is electrically isolated, then connecting the Earth pin to the screen will not make any difference in protecting the sensor from external interference.

200 mV (20 mV/V) output signal

We have a requirement for a 0 – 200mV (20mV/V) output with an excitation voltage of 10 V dc, and a 1/4″ BSP female process connection to measure oil pressure up to 100 psi gauge at 125°C.

The IMP will operate at media temperatures up to 135°C and it is possible to provide a version which has a 200 millivolt full scale output and female BSP thread pressure fitting.

- SKU ID: s1-imp-0015

- Part No: IMP-GP100-XA4-BEV-00-056

- Pressure Range: 100

- Units: psi

- Range Type: Positive Gauge (atm to +P)

- Output Signal: 20mV/V, 4-wire (X)

- Supply Voltage: 3-12Vdc

- Non-Linearity and Hysteresis: 0.25% FS (standard) (A)

- Thermal Zero Shift: 0.04% FS per °C (standard) (4)

- Electrical Connection: Large DIN plug (standard) (B)

- Process Connection: G1/4 female, 303 St/St (E)

- Media Exposed Seals: Viton (standard)(V)

- Special Requirements: Standard (000)

RS485 interface with 200 bar range

Is it possible to provide the IMP with a RS485 serial interface to measure over the range of 0 to 200 bar?

Yes RS485 is now an available output signal option for the IMP.

- SKU ID: s1-imp-0007

- Part No: IMP-G2003-R1A4-BAV-00-000

- Pressure Range: 0 to 200

- Units: bar

- Range Type: Positive Gauge (atm to +P)

- Output Signal: RS485 (ASCII version) (R1)

- Non-Linearity and Hysteresis: 0.25% FS (standard) (A)

- Thermal Zero Shift: 0.04% FS per °C (standard) (4)

- Electrical Connection: Large DIN plug (standard) (B)

- Process Connection: G1/4 male DIN 3852 (A)

- Media Exposed Seals: Viton (standard)(V)

- Special Requirements: Standard (000)

Output possible with 4 volt supply

I’m interested in finding a pressure transmitter which will operate from a power supply of 4 Vdc or less?

The highest output possible on the IMP with a 4 volt supply is a 25mV/V ratio-metric amplified output. This would provide a 0-100mV output over the full scale pressure range. The range of supply voltage for this option is 3-12V dc and the output is set to a tolerance of +/- 1% span.

Minimum ratiometric output

Is it possible to have an ratiometric output of 0.25 to 2.25Vdc with a 2.5Vdc supply?

The standard 0.5 to 4.5V output can only have a supply voltage of 5V ±0.5V supply, so it is not possible to go any lower than 4.5Vdc supply voltage with a 0.45 to 4.05 Vdc output.

2.5 volt output

Is a 0-2.5 volt signal output possible with the IMP pressure transmitter and what will be the minimum supply voltage?

Yes, a 0 to 2.5V signal output is possible and the minimum supply is 7 volts.

Highest mV output

What is the highest possible millivolt output possible with the IMP?

It is 20mV/V at 12V supply, therefore 240mV is the highest millivolt output.

100 millivolt output signal

I am looking at the IMP pressure transducer specification with a millivolt output, and need 100mV output, which option should I specify mV/V, mV/V or 10mV/V?

The IMP has a choice of 3 outputs with a millivolt output:

- mV/V – unrationalised, varies between 2.0 to 6.7 millivolts at full scale for each volt from the supply (2-30Vdc)

- 2mV/V – rationalised to produce 2 millivolts at full scale for each volt from the supply (2-30Vdc)

- 10mV/V – rationalised and pre-amplified to produce 10 millivolts for each volt from the supply (3-12Vdc)

We would suggest option 3 used with a regulated 10Vdc supply which will output 100 millivolts at full scale.

Bridge resistance

What is the resistance of the bridge on the millivolt output versions?

The strain gauge bridge resistance is 11 kohms +/-30%.

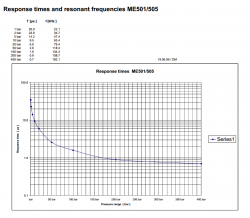

250 bar response time

Can you advise what the response time is for the IMP Industrial Pressure Transducer range. I’m looking at the 0 – 250Bar transducer?

The response time of the amplified outputs is 10 msec and for the mV/V output it is around 1 microsecond for a 250 bar range .

Amplified output response time

What is the response time of the amplified output version of the IMP pressure sensor?

It is less than 10 milliseconds for the 4-20mA and high voltage output versions.

0.5 to 4.5 vs 0 to 5 volt output

I have an IMP voltage output pressure transducer which has a 0.5 to 4.5Vdc, is there a difference between a 0 to 5Vdc and a 0.5 to 4.5 Vdc output?

Yes there is a difference, the 0 to 5 Vdc is a regulated output which remains relatively constant for different supply voltages over the operating range of 9-32Vdc.

The 0.5 to 4.5 Vdc is a common amplified output configuration for low power requirements such as automotive which are designed to run from a low 5Vdc power source. This type of output is ratiometric which means the output is proportional to the input supply voltage e.g. 4Vdc supply would produce a 0.4 to 3.6Vdc output.

There is also a regulated version of the 0.5 to 4.5Vdc output for the IMP pressure transducer which is regulated with any supply voltage from 8-16Vdc.

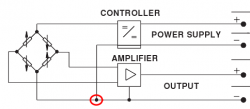

Converting 3 wire voltage output to 4 wire

Is it possible to convert the IMP pressure transducer from a 3 wire 0 to 10Vdc output to a 4 wire type?

Yes, but not as a 4 wire amplified circuit with an isolated supply and output, which is much less common today. What most manufacturers do today is split the supply/output negative common to a -ve supply and -ve output wire connection. It remains the same configuration electrically but with one wire split into two connections to create a fourth wire. Both negative connections will be floating at the same potential.

Zero and span setting tolerance for 4-20mA

What is the pass/fail criteria for the zero and span settings of the 4-20mA output on the IMP pressure transmitter?

In the factory the output is set to better than 0.5% full span, so since 16mA is the full span for a 4 to 20mA output signal, the IMP would pass production testing if the following was measured:

- 3.92mA < Zero Pressure < 4.08mA

- 19.92mA < 100% Full Scale Pressure < 20.08mA

This should not be confused with the accuracy tolerance of the device.

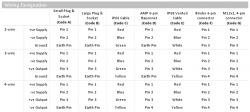

4-20mA DIN plug pin wiring

What is the pin wiring for a IMP pressure transmitter with a DIN plug and a 4-20mA output?

The positive connection is pin 1 and the negative connection is pin 2.

0 to 2.5 volt output signal

We are interested in the IMP voltage output pressure transducer and was wondering if it is possible to scale the output signal form 0 to 2.5 volts dc for a 0 to 20 bar g range?

It is not a standard configuration so that is why it is not included in specification, but it is possible to provide a custom scaling of 0-2.5Vdc instead of the closest standard output signal of 0-5Vdc.

10mV/V signal min. supply voltage

What is the minimum supply voltage that can be applied to power the 10mV/V output?

Them minimum voltage is 3Vdc.

Galvanic isolation

Can you please confirm whether the IMP pressure sensor is of the isolated type or in other words galvanically separated?

There is no galvanic isolation on the IMP. It is quite rare to find a manufacturer which makes a pressure sensor with this built-in. The simplest solution is to purchase a separate isolator module.

5V supply operation

Is it possible to use the IMP with a 5V supply?

Yes, all ratiometric output versions mV/V, 2mV/V, 10mV/V & 0.5 to 4.5Vdc output will operate from a 5 volt dc supply.

Pressure Range

Datum meaning

Can you specify what “datum” means when selecting a pressure range for the IMP pressure transducer?

In the context of the IMP pressure transducer, the datum refers to the pressure range reference as follows;

- Gauge datum means pressure is measured with respect to ambient atmospheric pressure.

- Absolute datum means pressure is measured with respect to full vacuum.

- Sealed Gauge datum means pressure is measured with respect to atmospheric pressure fixed at 1 bar absolute.

Lowest possible range

What is the lowest range possible for the IMP pressure sensor?

The IMP is limited to a minimum range of 0 to 1 bar, but if a lower range is required we would suggest the IMP-LR (stainless steel diaphragm) which has a range as low as to 0 to 50 mbar.

Reference required for excluding ambient pressure

The pressure range we require is ambient to 10 bar, so do we need an absolute pressure transmitter?

If you are only interested in measuring 10 bar excluding ambient air pressure, you would need a 0-10 bar gauge range, but if you want to measure 10 bar including ambient pressure, then you would need a 0-10 bar absolute.

760 mmHg negative gauge

I am searching for a low priced vacuum pressure transmitter to measure over the range from 0 to -760 mm Hg with an output range of 4-20mA. I do not need high accuracy and the application is inside a controlled ambient environment so rugged design is not necessary. Is it possible for the IMP be configured to measure this?

Yes, the IMP is capable of measuring a negative gauge pressure in the vacuum range. To help with selecting a pressure range, -760 mmHg (millimetres of mercury) is approximately equal to -1 bar or -15 psi which are standard IMP pressure ranges.

Accuracy

1 bar range accuracy over 0 to 250mbar

I am looking to use the IMP pressure transmitter to measure air at pressure in the range of 150 to 250 milibar. I am planning on selecting a 0.5bar range, however the application will involve pressures which may exceed the maximum rated overpressure. A 1 bar gauge range would provide an adequate overpressure, how would it perform measuring over the 0-250 millibar range?

The accuracy for the IMP is pro-rata of range, so if the range is doubled, the errors will double in size also. The standard accuracy of the IMP is 0.25% full scale, therefore the effective accuracy over the 0-250 mbar g measurement range would be 1%.

High resolution signal

We have an application where we require a high level of resolution from an amplified output pressure sensor and we would like to consider the IMP because it is a pressure transmitter which is low cost. However we cannot find any mention of output resolution on the IMP data sheet, so please could you advise what it is?

The IMP signal conditioning utilises a 12 bit digital to analogue amplifier and depending on the sensor range the resolution will be between 1/2048 (0.049%) and 1/4096 (0.024%).

Although this is well inside the quoted accuracy options for the IMP of 0.25% and 0.1% full scale best straight line, we would not recommend the IMP is used for applications such as leak testing or profiling dynamic pressure changes where a high level of resolution is required.

Alternatively we would recommend the DMP331i for high resolution applications because it incorporates a 16 bit A/D converter which produces a much higher resolution in the order of 1/65,536 (0.0015%), but it is a higher cost sensor than the IMP.

Environmental Conditions

Operating temperature range

What is the temperature range for the IMP pressure sensor?

The media operating range is ‐20°C to +125°C as standard, and +150°C with the integrated cooling element. The ambient operating range is -20 to +80°C.

150°C air pressure

The maximum media temperature specified on the data sheet is 135degC. The media will be air at a temperature up to 150degC, is it possible to increase the operating range?

There is an optional cooling element which acts temperature isolator to extend the media temperature range to maximum of +150 degC.

70°C water temperature

Is the IMP pressure transducer suitable for water at a temperature from 0 to 70C?

Yes, the operating temperature range for the IMP is -20 to +135 degC (-4 to +275 degF) for the pressure media and -20 to +80 degC (-4 to +176 degF) for the environment around the transducer.

250°F process temperature

Our process temperature runs at 250F, is that within in the operating temperature of the IMP pressure transmitter?

The maximum process temperature tolerated by the IMP as standard is 135 degC (275 degF) which is within the required temperature. There is also the option for an integrated cooling element which raises the tolerance to 150 degC (302 degF).

300°F with 0-5Vdc output

I’m looking for a high temperature 0-5Vdc 3 wire output pressure transducer for use on freshwater up to 300 degrees Fahrenheit, can the IMP do this?

The IMP has the option for a 150degC (302°F) cooling element to protect the sensor from high temperature water and steam. The IMP can also be supplied with a 0-5 Vdc output signal.

Media Compatibility

Internal O-ring material

Is there any O ring material used in the construction of the IMP pressure sensor inside the process connection exposed to the measurement side?

A Viton (FKM) elatomer is used to provide the seal between the ceramic diaphragm and stainless steel inside the process connection port.

Viton is the default material, but other materials can be selected instead such as EPDM, NBR, FFKM or Fluorosilicone.

R404a refrigerant

Is the IMP pressure transmitter compatible with R404a refrigerant?

Although R404a is compatible, it is the type of oil that the refrigerant is mixed with that is critical to the compatibility in this case.

The critical component that is at risk from damage is the elastomer seal which is used to seal between the ceramic diaphragm and stainless steel housing inside the sensor, on the side that is exposed to the refrigerant.

Available as standard there is a choice of seals that can be specified which includes Viton, NBR, EPDM or Chemraz. If none of these are compatible with the type of oil used, it may still be possible to consider an alternative non-standard seal option which will be compatible.

Oil

One of the sensors we require will be used on oil, will the IMP pressure transmitter work with oil?

The IMP is compatible with oil as long as it is mineral, diesel or common engine oil. For other types of oil check the compatibility with the parts exposed to the media which are detailed in the product parameters section above.

Heptane and engine oil

Please could you confirm whether the wetted parts of the IMP pressure transmitter are compatible with engine oil and heptane?

Heptane is compatible with the wetted parts which consist of a ceramic diaphragm, stainless steel process port and Viton elastomer seal. There are many types of engine oil, but it is compatible with regular engine oil used in petrol or diesel engines.

Calibration

Calibration adjustment of output

Is it possible to change the calibration and make adjustments to the output of the IMP pressure sensor?

This is a fixed range device and cannot be adjusted by the user. It can be sent back to the factory and adjusted but only for calibration purposes, and not changed to a different pressure range.

Calibration report types

Is it possible to have a calibration certificate for the IMP pressure transmitter?

As standard the IMP comes with a 3 points rising and 2 points falling calibration report. The calibration data is collected during manufacture using equipment that is regularly calibrated with traceable equipment. The calibration report only includes information about the sensor, so if you need additional traceability information, a separate calibration certificate can be provided with additional calibration points, manufacturer, model and serial number of the calibration equipment used, the calibration technicians name and calibration date.

Pressure test certificate

Is it possible to produce a pressure test certificate for the IMP pressure transducer?

A pressure test certificate is not provided as standard, but it is possible to provide this as a custom production acceptance test (PAT) if you can define the requirements such as pressure levels, number of cycles, duration at each pressure point etc….

UKAS traceability of calibration certificates

We have a set of IMP pressure transducers with calibration certificates included. Could you indicate if these certificates conform to UKAS traceable standards?

The cal certs provided with these sensors show data collected using production calibration equipment which is regularly calibrated by a UKAS certified calibration laboratory.

It is very unusual to calibrate sensors directly using a UKAS laboratory and relatively expensive. However, if you trace back the source of calibration for the test equipment used, you will usually end up at a UKAS laboratory or international equivalent depending on where the sensors are made, especially where the ISO9000 approved facilities.

Interpretation of calibration report errors

Could you provide the value of the maximum allowable error out of full scale for the IMP pressure transmitter, also how should the calibration certificate be interpreted for variation from zero, 50%, FRO, 50% and zero?

The precision of the IMP pressure transmitter is +/- 0.25% FS NLH (Full Scale, Non-Linearity and Hysteresis). The calibration report shows the actual output at 0, 50%, FRO, 50%, 0, these 5 points describe the order of the calibration process of 3 increasing calibration points followed by 2 decreasing calibration points. If all the points are plotted on a graph of actual pressure against volts out and a line is drawn through the middle of all the points, each one would fall within an error band of 0.25% of the full scale output.

Part Numbers

Part number configuration

I have a part number for the IMP pressure transmitter but I have no way of identifying what it means, please could you explain the part number configuration for this device so that I can determine it’s specification.

You can compare the part number with the IMP part number coding.

Applications

Acetone, MEK & Ethanol printing inks

We are sensing pressure on ink lines and need to create an alarm when the pressure falls below 5 psi. Do you have a sensor with a 0-10 volt output, which will work on Acetone, MEK & Ethanol printing inks as well as water based ink?

For printer ink solvents we would recommend using the IMP with a EPDM seal.

- SKU ID: s1-imp-0018

- Part No: IMP-GP050-7A4-BAE-00-000

- Datum: Gauge (G)

- Pressure Range: 50 psi (P050)

- Output: 0 – 10V, 3-wire (7)

- Non-Linearity and Hysteresis: 0.25% FS (standard) (A)

- Thermal Zero Shift: 0.04% FS per °C (standard) (4)

- Electrical Connection: Large Plug & Socket, GDM3009, DIN43650 (B)

- Process Connection: G1/4 male DIN 3852 (A)

- Internal Seal Material: EPDM (E)

Vacuum range for air, water & brake fluid

I’m looking for a sensor for room temperature operation on media which could be air, water or brake fluid but most often air. The spec should include a pressure range of -1 to 0 bar and an output of 0-10Vdc. I will also need a calibration certificate.

We would suggest an IMP with the vacuum range and output signal requested which are both standard options, plus an EPDM O ring to seal between the ceramic sensing element and process port, for compatibility with brake fluid.

- SKU ID: s1-imp-0016

- Part No: IMP-GM1P0-7A4-BAE-00-000

- Pressure Range: 0 to -1

- Units: bar

- Range Type: Positive Gauge (atm to +P)

- Output Signal: 0 – 10V, 3-wire (7)

- Non-Linearity and Hysteresis: 0.25% FS (standard) (A)

- Thermal Zero Shift: 0.04% FS per °C (standard) (4)

- Electrical Connection: Large DIN plug (standard) (B)

- Process Connection: G1/4 male DIN 3852 (A)

- Media Exposed Seals: EPDM (E)

- Special Requirements: Standard (000)

Air evacuation control

I’m looking for a pressure sensor which will be used to control a vacuum pump. The vacuum pump will evacuate the air within a vacuum tumbler, and maintain vacuum for a set duration of time. The sensor will be located off the vacuum tumbler, in between a pressure capsule and the vacuum pump. Using a T-Junction, the sensor will be measuring the pressure leaving the vacuum tumbler to the vacuum inlet and the pump. The measurement range will be 0 to 1000 mbar absolute, the required output is 0-10 volts with a integrated cable. Please can you advise to you most suitable and affordable sensor.

The IMP is a low cost industrial pressure sensor suitable for use over the low vacuum range from 0 to 1000 mbar absolute.

- SKU ID: s1-imp-0008

- Part No: IMP-A1000-7A4-CAV-02-000

- Pressure Range: 0 to 1000

- Units: mbar

- Range Type: Absolute (0 to +P)

- Output Signal: 0 to 10V, 3-wire (7)

- Non-Linearity and Hysteresis: 0.25% FS (standard) (A)

- Thermal Zero Shift: 0.04% FS per °C (standard) (4)

- Electrical Connection: IP66 cable gland with 2m of cable (C)

- Process Connection: G1/4 male DIN 3852 (A)

- Media Exposed Seals: Viton (standard)(V)

- Special Requirements: Standard (000)

Nitrogen cylinder charge level

I’m looking for a pressure transducer with a 0 – 1000 psi range, about 12Vdc input power and dc output, 1/8″ NPT input port. This transducer will be used to monitor the charge level of a nitrogen cylinder.

An IMP pressure transducer with a 0-5Vdc output will work from a 9-30Vdc supply and has the option for a 1/8 NPT male fitting. The IMP is also compatible with pressurised Nitrogen gas.

- SKU ID: s1-IMP-0008

- Part No: IMP-GP1K0-6A4-BNV-00-000

- Pressure Range: 1000

- Units: psi

- Range Type: Positive Gauge (atm to +P)

- Output Signal: 0 – 5V, 3-wire (6)

- Non-Linearity and Hysteresis: 0.25% FS (standard) (A)

- Thermal Zero Shift: 0.04% FS per °C (standard) (4)

- Electrical Connection: Large DIN plug (standard) (B)

- Process Connection: 1/8 NPT male (N)

- Media Exposed Seals: Viton (standard)(V)

- Special Requirements: Standard (000)

Cleaning plant vacuum pressure

Please suggest a sensor for measuring vacuum pressure on cleaning plant to measure over 0 to -50kPa with a 0 to 10 volt output and any kind of connector so that it can be wired to?

We would suggest the following specification for your application:

- SKU ID: s1-imp-0001

- Pressure Range: 0 to -50

- Units: kPa

- Range Type: Positive Gauge (atm to +P)

- Output Signal: 0 – 10V, 3-wire (7)

- Non-Linearity and Hysteresis: 0.25% FS (standard) (A)

- Thermal Zero Shift: 0.04% FS per °C (standard) (4)

- Electrical Connection: Large DIN plug (standard) (B)

- Process Connection: G1/4 male DIN 3852 (A)

- Media Exposed Seals: Viton (V)

Controlling heating system water pressure to 1.4bar

I’m looking for a 4-20mA output transducer for monitoring water pressure in heating system to keep pressure at 1.4 bar by initiating a circuit to drive a pump.

We would suggest this IMP spec for providing a 4-20mA output for heating system water pressure:

- SKU ID: s1-imp-0004

- Part No: IMP-G2000-5A4-BAV-00-000

- Pressure Range: 0 to 2

- Units: bar

- Range Type: Positive Gauge (atm to +P)

- Output Signal: 4 – 20mA, 2-wire (5)

- Non-Linearity and Hysteresis: 0.25% FS (standard) (A)

- Thermal Zero Shift: 0.04% FS per °C (standard) (4)

- Electrical Connection: Large DIN plug (standard) (B)

- Process Connection: G1/4 male DIN 3852 (A)

- Media Exposed Seals: Viton (standard)(V)

- Special Requirements: Standard (000)

60 psi water tower pressure sensor for SCADA

I need a 60 psi water tower pressure sensor which will be used to regulate tower fill and drain levels and must have a 4-20 ma to run to a SCADA system, plus a 1/4 NPT male fitting.

This IMP specification would meet your requirements:

- SKU ID: s1-imp-0005

- Part No: IMP-GP600-5A4-BCV-00-000

- Pressure Range: 0 to 60

- Units: psi

- Range Type: Positive Gauge (atm to +P)

- Output Signal: 4 – 20mA, 2-wire (5)

- Non-Linearity and Hysteresis: 0.25% FS (standard) (A)

- Thermal Zero Shift: 0.04% FS per °C (standard) (4)

- Electrical Connection: Large DIN plug (standard) (B)

- Process Connection: 1/4 NPT male (C)

- Media Exposed Seals: Viton (standard)(V)

- Special Requirements: Standard (000)

Oil pressure spikes

I have a requirement for a pressure sensor for measuring oil pressure on a dynamic system, and therefore will need a snubber to protect the pressure sensor from sudden changes in pressure. The other specification requirements are a 3.5barg pressure range, 4-20mA output, 1/-19 BSPP male port, M12 electrical connector and an accuracy of 0.25%.

The following IMP configuration has a snubber incorporated into the 1/4 BSP thread to restrict the response of the pressure sensor to smooth out pressure spikes generated by a dynamic oil pressure system.

- SKU ID: s1-imp-0006

- Part No: IMP-G3500-5A4-GJV-00-000

- Pressure Range: 0 to 3.5

- Units: bar

- Range Type: Positive Gauge (atm to +P)

- Output Signal: 4 – 20mA, 2-wire (5)

- Non-Linearity and Hysteresis: 0.25% FS (standard) (A)

- Thermal Zero Shift: 0.04% FS per °C (standard) (4)

- Electrical Connection: M12 4 pin connector (G)

- Process Connection: G1/4 male DIN 3852 with Snubber (J)

- Media Exposed Seals: Viton (standard)(V)

- Special Requirements: Standard (000)

Related Documents

Specification data sheet

Request Product Price

Please select the options you require for the IMP Low Cost Pressure Sensor in your application and request a quote.

"*" indicates required fields