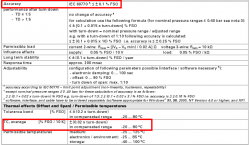

High precision pressure transmitter with an accuracy of 0.1%FS BSL NLHR and digitally adjustable pressure ranges from 400mb up to 40 bar gauge & absolute.

Product Parameters

- Pressure Ranges: 0.4 up to 40 bar gauge or absolute

- Accuracy: 0.1% full scale

- Output Signal: 4-20mA or 0-10V dc output signal, RS485 ModBus RTU (14 bit res)

- Electrical Connections: DIN 43650 (ISO4400) plug and socket, Binder 5 or 7 pin connector, M12 x 1 4 pin connector, IP67/68 cable outlet and field housing

- Pressure Connections: G1/4, G1/2, DIN3852 and EN837, G1/2 flush, G1/2 open port, 1/4NPT male, 1/2NPT male

- Media Compatibility: SS316L pressure port and diaphragm, FKM internal seals

- Special Features: 10 to 1 maximum turndown adjustment of pressure range via RS232 interface

- Special Options: ATEX and IECEx approval for Intrinsic safety II 1 G EEx ia IIC T4

Product Description

The DMP 331i high accuracy pressure transmitter sensor uses a silicon strain gauge diaphragm housed in an oil filled capsule and the repeatable & low hysteresis properties of silicon are exploited by the digital amplifier with 14 bit A/D conversion to provide a highly precise pressure measurement over the operating temperature range.

The DMP-331i high accuracy pressure transmitter is available with ATEX/IECEx approval for intrinsically safe use in hazardous environments

Product Help

RS232 configuration interface adapter

In the DMP33i data sheet an adaptor is mentioned under superscript 9. What adapter would this be referring to?

This is referring to the CIS-G RS232 adapter and software which enables you to configure the DMP331i via a computer. To use this you will also need a DMP331i that has been enabled at the factory when manufactured. This can be specified by adding -121 on the end of the part number.

The RS232 is a bit misleading, it’s specific to the configuration software so there is no protocol or anything to allow you to utilise the coms with your own software interface.

Air inlet depression and exhaust back pressure

I need to measure the air inlet depression over 0 to -1 bar gauge on a diesel engine, and also the exhaust back pressure 0 to 1 bar gauge. What will be the accuracy of this of this transducer, and also I will need to be able to log at 4Hz minimum?

The accuracy of the -1000 to +1000 mbar is 0.1%, so it will be 2 mbar, however the reading resolution will be much better than this if you are interested in detecting pressure changes rather than absolute accuracy.

The response time is approx 5 msec, so it will work fine for your minimum 4 Hz logging rate.

For measuring exhaust back pressure, it is important not to expose the transducer to directly to hot exhaust gases, since the upper temperature limit is 125°C for the diaphragm, and 85°C for the electronics housing.

- SKU ID: s1-dmp331i-73-28150

- Pressure Range: -1000 to +1000

- Units: mbar

- Range Type: Compound Gauge (-P1 to +P2)

- Output Signal: 0 – 10V, 3-wire

- Accuracy: 0.1% FSO

- Electrical Connection: M12 x 1 connector (4 pin)

- Process Connection: G1/4 DIN3852 male

Temperature error 80-90°C

I am considering the DMP331i high accuracy pressure transducer for a high temperature application at about 80°C to 90°C steam temperature. How will this impact the 0.1% full scale accuracy indicated for the DMP331i and what could be done to limit this impact?

The 0.1% FS accuracy does not include the temperature error which is an additional 0.02%FSO/10K = 0.02%/10K. So from a room temperature of approx. 20°C to a temperature of 90°C, the additional error could be as much as 0.12% FS (o.22% FS in total).

To reduce this additional temperature error and assuming you have the ability to calibrate the sensor when the temperature is between 80 and 90°C, you can treat the error from room temp up to 90degC as a calibration shift, since you are only interested in optimising performance between 80 and 90°C. So the easiest way to reduce the temperature error is to check the output signal at zero and full scale pressure when the temperature is at it’s mid-point i.e. 85°C. The temperature error will then become 0.02% FS over the 10°C (10K) temperature band, or 0.12% FS when combined with the room temperature pressure accuracy.

If you are not able to set full scale pressure, an even simpler method is to to just check the zero shift at 85°C since most of the thermal error is typically contributed by the thermal zero shift.

Accuracy of 2000 mbar range re-scaled to 1200 mbar

In terms of accuracy, what does the 0.1% FSO mean for a DMP331i high accuracy pressure transmitter scaled to 1200mbar, does that mean it will measure within plus/minus 1.2mbar?

Yes this is correct for the room temperature accuracy. According to the data sheet spec the DMP331i is +/-0.1% FS within the 5:1 turndown range of the output. So a 2 bar range scaled to 0 – 1200 mbar would be within the 5:1 limit, and therefore the accuracy would be +/-1.2 mbar at room temperature.

However if the measurement is not taken at room temperature you will also need to consider the temperature error which is an additional 0.02%FSO/10K x Turn down would be 0.02% x 2000mbar/1200mbar = +/-0.4mbar/10K.

Adjusting 35 bar range to 400 psi & 100 psi

Can a 35 barg range DMP331i pressure transmitter be re-ranged to measure 0 to 400psi and 100psi?

Yes, it can be turned down by as much as 10:1, so in this case the user can adjust the range to 0 to 3.5 bar (52.50 psi) if necessary. The range is only configurable via the optional RS232 interface and software.

If the required ranges are fixed and unlikely to be changed in the future, they can be set in the factory without the need for purchasing the re-ranging option.

110-2002-3-1-TA0-N40-1-111

What is the product spec description for a DMP 331i with the part number 110-2002-3-1-TA0-N40-1-111?

- SKU ID: s1-dmp331i-0001

- Part No: 110-2002-3-1-TA0-N40-1-111

- Pressure Range: 20

- Units: bar

- Range Type: Positive Gauge (atm to +P)

- Output Signal: 0 – 10V, 3-wire

- Electrical Connection: IP67 seal with 2m of cable

- Process Connection: 1/4 NPT male

Related Documents

Specification data sheet

Request Product Price

Please select the options you require for the DMP331i High Accuracy Pressure Transmitter in your application and request a quote.