Dual analogue output signal transmitter for simultaneous measurement of media pressure and temperature. Pressure ranges from 100 mbar up to 1000 bar and temperature measuring range from -25 to 100 DegC.

Product Parameters

- Pressure Ranges: 0-100 mbar up to 0-1000 bar gauge or absolute

- Pressure Accuracy: +/- 0.5% FS TSL with optional 0.25% or 0.1%

- Temperature Measurement Range: Any from -25 up to 150 DegC

- Temperature Accuracy: +/-2 DegC

- Output Signal: 2 x 3 wire 4-20mA, 0-5V, 0-10V, or 0-20mA

- Supply Voltage: 15-30Vdc

- Electrical Connections: DIN plug, Binder connector, Military connector, PE, PUR or Teflon cable

- Pressure Connections: G1/2 male recessed exposed or flush diaphragm

- Media Compatbility: All welded stainless steel 316L with Viton pressure connector seal

- Dimensions: 24mm diameter, 74mm standard body length , 101mm with cooling fins

- Response Time: < 1msec

- Special Features: Combined pressure and temperature measurement, zero and span adjustment with removable connector versions

- Special Options: Cooling fin option for media temperatures between 100-150 DegC. All Titanium construction, Oxygen service, food compatibility, compound ranges

Product Description

The ATM-T pressure and temperature transmitter combines the measurement of two process parameters in one device saving installation time and space.

The sensor measures pressure via an oil filled silicon chip strain gauge capsule.

The temperature is measured behind a oil filled isolation diaphragm so there are no temperature probes extending in to the process media.

In order to ensure adequate thermal conductivity the design includes an exposed diaphragm so that no media temperature is lost through the pressure port before it reaches the temperature sensing components.

For different applications such as food and drink or Oxygen service, a choice of compatible oil fills are available to reduce the risk of contamination if the isolation diaphragm is damaged.

For high temperature applications between 100 and 150 degrees Celsius, cooling fins can be specified to reduce the temperature exposed to the electronics housing.

An anti-corrosion all Titanium wetted parts version is also possible for use with salt water.

Product Help

Separate or multiplexed P/T signals

I have a question about the dual P/T signals, do they provide an output to separate pins or are they multiplexed?

The pressure and temperature signals are transmitted on separate pin output connections, but they do share the same ground connection, so they are treated as separate in terms of multiplexing.

263.1314.0147.01.U

What is the product configuration for a ATM/T pressure & temperature pressure transducer with the part number 263.1314.0147.01.U?

- SKU ID: s1-atmt-6-14683

- Part No: 263.1314.0147.01.U

- Pressure Range: 0 – 35 Bar (500 Psi)

- Output Signal: 0-10V / 3-wire (shared GND with temperature sensor)

- Temperature Range: 0 to 200°F

- Output: 0-10V / 3-wire (shared GND with pressure sensor)

- Electrical Connection: DIN 43650 with metal threaded part, demountable

- Process Connection: G 1/2 male, frontal diaphragm

Flush diaphragm up to 600 bar

I’m confused by the statement on the data sheet for each type process connection, it states that a pressure range is not possible above 600 bar for the G1/2 frontal or flush diaphragm versions, although pressure ranges are available up to 1000 bar?

Although it is not mentioned on the data sheet, it is possible to supply the ATM/T with a standard G1/2 male fitting that is enclosed around the diaphragm for ranges above 600 bar.

Shared pressure & temperature wiring

Is the pressure and temperature completely isolated from each other or is some of the wire connections shared between the two?

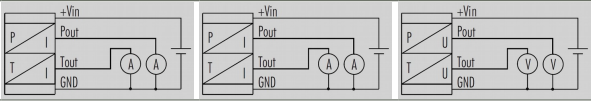

The pressure & temperature signal are not isolated from each other, both share the same negative common ground connection. The diagram below shows the wiring configurations for the 4-20mA, 0-20mA & 0-5/10V output versions respectively.

Compensated temperature is lower than media temperature

I am intending to use the ATM/T combined temperature and pressure transducer to measure a process fluid up to a temperature of 150C. Will the limited compensated temperature range of -25 to +85 degC specified on the datasheet affect the performance at 150degC?

The compensated temperature range refers to the temperature of the sensor and electronics which will be different to the process temperature since they are protected by the 150 degC cooling element. It is unlikely that the temperature will exceed 85degC at the sensor end of the cooling element (assuming ambient temperature is lower than 85 degC), and this is why the compensated temperature range is limited to a lower temperature.

Choosing between a frontal and flush diaphragm

What is the difference between the two process connection types mentioned for the ATM/T dual pressure and temperature sensor?

The G1/2 flush diaphragm is an all welded and completely flush with no crevices to encourage the build up of solids and bacteria, so it is good for hygienic applications.

The G1/2 frontal diaphragm is slightly recessed and is also welded but there is a small gap between the welded ring and the diaphragm on the inside diameter, so it is not considered hygienic, but it is lower cost and better protected from damage than the flush diaphragm.