What pressure range you select for a pressure measurement application affects the accuracy and the service life of a pressure transducer.

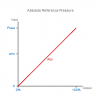

Most pressure sensors rely on the fractional movement of a diaphragm with a Wheatstone bridge strain gauge circuit to produce an electrical output signal that is proportional to pressure.

As a general rule the lower the pressure range, the larger the diameter of the diaphragm to ensure enough movement and thus sensitivity of measurement. The stiffness of a diaphragm is a function of the diameter or cross sectional area, its thickness and the rigidness of the diaphragm material.

In order to ensure the best accuracy and maximum signal output for a pressure sensor a manufacturer will use different diaphragms for different pressure ranges. Therefore it is important not too select a pressure range that is too high otherwise the accuracy and output signal will be too low. On the other hand if you select a pressure range that is too low you will risk over stressing a diaphragm and causing a performance shift or worse irreparable damage.

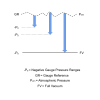

One method for determining the required pressure range is to consider the maximum and minimum pressure that is likely to be produced by the system being measured.

The maximum pressure should reflect the maximum operating pressure, and any over-pressure condition should be allowed for within the over-pressure rating of the device. If the over-pressure rating of the device is not sufficient, the pressure range should be increased until the over-pressure rating is sufficient.

The minimum pressure should reflect a low pressure condition that is regularly produced by the system. All systems will see zero pressure at some point so avoid using zero if the system is rarely vented to atmosphere.

Then add the minimum and maximum pressure together to calculate the pressure range.

Pmin + Pmax = Prange

This method will ensure that the pressure sensor is mostly operating around its mid-point pressure extending its service life without compromising too much accuracy.

Related Help Guides

- Determining the hydrostatic pressure range for a tank level sensor

- Measuring vacuum with negative gauge or absolute ranges

- What is the difference between gauge and absolute pressure measurement

- What is difference between working, burst and over pressure

- What is the difference between vacuum and absolute pressure

- What does negative and positive gauge pressure mean

- Measuring negative pressure using a positive differential pressure range

Related Technical Terms

- Bidirectional

- Burst Pressure

- FS – Full Scale

- Gauge Reference Pressure

- Negative Gauge Pressure

- Reference Pressure

- SG – Sealed Gauge

- Static Line Pressure

- Vented Gauge

Related Product and Application Guides

Low Pressure Range

Low Pressure Range Barometric Pressure

Barometric Pressure Overpressure Protection

Overpressure Protection Suction Pressure

Suction Pressure Absolute Pressure

Absolute Pressure Compound Pressure Ranges

Compound Pressure Ranges Hydrostatic Pressure

Hydrostatic Pressure

Related Application Questions and Answers

Contact us about this Selecting a pressure range for optimal service life and accuracy page to request more information, or to discuss your application requirements.