Current output transmitters for use in applications for measuring pressure of high temperature steam such as sterilizing autoclaves, food processing and power generation. These current signal output pressure transmitters include integral cooling features for protecting the transmitter electronics from steam temperatures which would otherwise cause damage to standard industrial pressure transmitters.

Products

IMP Industrial Pressure Sensor - The IMP industrial pressure sensor, has a piezo‐resisitive ceramic pressure sensor giving it excellent media compatibility

IMP Industrial Pressure Sensor - The IMP industrial pressure sensor, has a piezo‐resisitive ceramic pressure sensor giving it excellent media compatibility DS200P Sanitary Low Range Pressure Gauge, Switch and Sensor - All in one electronic switch, gauge and sensor designed specifically for use in the food, drink and biomedical industry for measuring process pressures.

DS200P Sanitary Low Range Pressure Gauge, Switch and Sensor - All in one electronic switch, gauge and sensor designed specifically for use in the food, drink and biomedical industry for measuring process pressures.

DMP331P Hygienic Flush Pressure Transmitter

DMP331P Hygienic Flush Pressure Transmitter IMP Low Cost Pressure Sensor

IMP Low Cost Pressure Sensor DMK331P Flush Diaphragm Pressure Sensor

DMK331P Flush Diaphragm Pressure Sensor DS201P High Range Flush Pressure Gauge, Switch and Sensor

DS201P High Range Flush Pressure Gauge, Switch and Sensor

Applications

300 F protected 100 psi pressure transmitter - The IMP is a low cost pressure transmitter which has the option for a built-in process connector extender designed to reduce the temperature.

300 F protected 100 psi pressure transmitter - The IMP is a low cost pressure transmitter which has the option for a built-in process connector extender designed to reduce the temperature. 20 barg 4-20mA output 200degC steam pressure sensor for process control use - A hi-temp media 200°C/392°F max gauge pressure sensor for process control use to measure pressure of steam over a range of 0 to 20 bar g from the 1/2 BSP flush diaphragm male process connection, and sending the corresponding 4-20mA signal through the M12 connector electrical connection.

20 barg 4-20mA output 200degC steam pressure sensor for process control use - A hi-temp media 200°C/392°F max gauge pressure sensor for process control use to measure pressure of steam over a range of 0 to 20 bar g from the 1/2 BSP flush diaphragm male process connection, and sending the corresponding 4-20mA signal through the M12 connector electrical connection. 5 barg 4-20mA output pressure sensor for steam sterilization up to 150C/300F - A high temperature media protected pressure sensor for steam sterilizing use to measure pressure of steam over a range of 0 to 5 bar g from the G1/4 male process connection, and sending the corresponding 4-20mA signal through the DIN plug electrical connection.

5 barg 4-20mA output pressure sensor for steam sterilization up to 150C/300F - A high temperature media protected pressure sensor for steam sterilizing use to measure pressure of steam over a range of 0 to 5 bar g from the G1/4 male process connection, and sending the corresponding 4-20mA signal through the DIN plug electrical connection. High temperature 4.0 bar absolute range 4-20mA output steam pressure sensor for sterilizing use - A high temperature protected absolute pressure sensor for steam sterilizing use to measure pressure of steam over a range of 0.0 to 4.0 bar abs from the 1/4 BSP P male process connection, and sending the corresponding 4-20mA signal through the Hirschman electrical connection.

High temperature 4.0 bar absolute range 4-20mA output steam pressure sensor for sterilizing use - A high temperature protected absolute pressure sensor for steam sterilizing use to measure pressure of steam over a range of 0.0 to 4.0 bar abs from the 1/4 BSP P male process connection, and sending the corresponding 4-20mA signal through the Hirschman electrical connection.

150psig range 4-20mA high temperature pressure sensor for steam generator system use

150psig range 4-20mA high temperature pressure sensor for steam generator system use 10 barg range 4-20mA output steam pressure sensor for food processing use

10 barg range 4-20mA output steam pressure sensor for food processing use 10 bar g steam pressure transmitter

10 bar g steam pressure transmitter 16 bar, 200°C steam pressure transmitter and gauge

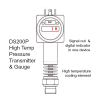

16 bar, 200°C steam pressure transmitter and gauge Measuring steam pressure up to 10bar with analog/digital output

Measuring steam pressure up to 10bar with analog/digital output Autoclave pressure sensor and display with 10 bar range

Autoclave pressure sensor and display with 10 bar range 320 degF steam temperature, 100 psi pressure transmitter

320 degF steam temperature, 100 psi pressure transmitter 25 kg/cm2 high temperature steam pressure transmitter

25 kg/cm2 high temperature steam pressure transmitter

- Saturated steam pressure transmitter for 185psi max pressure & 392F max temp

- 10 bar g steam pressure transmitter and indicator

- 270 degC steam pressure sensor with a 60 bar range

- 25 psi steam pressure measurement with a transmitter & display

Product Help

Steam temperature

Is steam temperature always the same value?

Under standard atmospheric conditions water turns to a gas and produces steam at a temperature of 100 degC / 212 degF, however this boiling point temperature is dependent on the pressure. As the pressure increases, the point at which water turns to a gas is a higher temperature. For example at a pressure of 10 bar gauge, the temperature at which steam is produced is 184 degC / 363.2 degF.

Maximum operating temperature

What is the highest operating temperature limit of the pressure transmitter?

When specifying a pressure transmitter for use on steam, it is important to determine the steam temperature by using a published table, online calculator or formula. At higher pressures it will become increasingly difficult to find suitable pressure transmitters because many will not have a sufficiently high enough maximum operating temperature.

Higher temperature steam protection

How are pressure transmitters protected from steam at higher temperatures?

Many of the pressure transmitter technologies that are widely used by manufacturers are not suitable for direct contact with high temperature steam, with typical operating limits from 100 to 125 degC / 212 to 363.2 degF. Therefore it is necessary to add protection components between the pressure transmitter and steam to act as a heat sink to cool the media in close proximity to the transmitter.

The high temperature protection components vary in mechanical design; some allow the steam to pass through, whilst others will isolate the steam using an oil filled isolation diaphragm seal. The majority of these design concepts rely on providing sufficient surface area of thermally conductive material to make contact with the surrounding cooler ambient air, and a restriction to reduce steam volume or a membrane to block it altogether, to increase the cooling effect.

Checklist for steam pressure transmitter requirements

Define your steam pressure transmitter requirements using this checklist:

- Pressure range?

- Current output type?

- Accuracy?

- Electrical connection?

- Media type? Steam

- Maximum media temperature?

- Maximum ambient temperature?

- Process connection?