Pressure data loggers which combine a battery, logger & pressure sensor all in one standalone instrument.

A pressure data logger is an instrument which incorporates a pressure measuring device with a data storage memory and firmware, or separate computer software and interface to facilitate the recording of pressure values.

To program the pressure datalogger and retrieve data you will need to connect a computer via a digital interface cable and use the provided logger software.

A pressure data logger can be setup by the user to commence recording at a certain time or event, at a preset sample rate.

Once the pressure data logger has completed collecting data, the software can be utilised to analyze or transfer the data to a data file for export to another application program.

Products

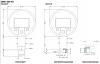

Submersible IP68 Water Pressure Data Logger - P-TRITON-P logger is completely waterproof for flood protection and battery powered with a typical battery life of 10 years.

Submersible IP68 Water Pressure Data Logger - P-TRITON-P logger is completely waterproof for flood protection and battery powered with a typical battery life of 10 years. DM01 Multi-Range High Accuracy Pressure Gauge - High precision digital pressure gauge with 0.05% full scale accuracy, exchangeable pressure range modules from 100 mbar (1.5 psi) up to 400 bar (6000 psi).

DM01 Multi-Range High Accuracy Pressure Gauge - High precision digital pressure gauge with 0.05% full scale accuracy, exchangeable pressure range modules from 100 mbar (1.5 psi) up to 400 bar (6000 psi).

High Frequency Response 1000 Hz Sampling Rate Pressure Data Logger

High Frequency Response 1000 Hz Sampling Rate Pressure Data Logger DM01-500-HD High Range Digital Pressure Gauge

DM01-500-HD High Range Digital Pressure Gauge LEO Record (Ei) Capo Low Pressure Logger

LEO Record (Ei) Capo Low Pressure Logger LEO Record (Ei) Pressure Data Logger

LEO Record (Ei) Pressure Data Logger

Applications

50,000 psi logger, indicator and sensor for hose burst testing - High pressure indicator, logger and pressure sensor to measure between 0 and 50,000 psi (~3500 bar) for hose burst tests.

50,000 psi logger, indicator and sensor for hose burst testing - High pressure indicator, logger and pressure sensor to measure between 0 and 50,000 psi (~3500 bar) for hose burst tests. 40,000 psi pressure sensor and data logger - Transducer and data logger capable of recording pressure over time for a system which has a max pressure of 40000 psi.

40,000 psi pressure sensor and data logger - Transducer and data logger capable of recording pressure over time for a system which has a max pressure of 40000 psi. Recordable indicator and sensor up to 30000 psi for pressure test rig - I'm looking for a sensor and panel indicator for a pressure test rig to measure up to 30,000 psi.

Recordable indicator and sensor up to 30000 psi for pressure test rig - I'm looking for a sensor and panel indicator for a pressure test rig to measure up to 30,000 psi. Hydraulic press logger for recording up to 10,000 psi with 0.1 sec logging rate - Recording pressures up to 10,000 psi on a hydraulic press with a fast logging rate.

Hydraulic press logger for recording up to 10,000 psi with 0.1 sec logging rate - Recording pressures up to 10,000 psi on a hydraulic press with a fast logging rate.

Hydraulic piston recorder & display with 2 pressure sensors for both directions

Hydraulic piston recorder & display with 2 pressure sensors for both directions 1600 bar data acquisition and recording system

1600 bar data acquisition and recording system 30,000 psi pressure sensor with recording indicator for data acquisition

30,000 psi pressure sensor with recording indicator for data acquisition 500 kPa g range rupture disk blowing digital display pressure gauge and logger

500 kPa g range rupture disk blowing digital display pressure gauge and logger Hydraulic puller-tensioner bar pressure to kilonewton load HMI display & logger

Hydraulic puller-tensioner bar pressure to kilonewton load HMI display & logger 30 mbar pressure logger for monitoring natural gas pressures

30 mbar pressure logger for monitoring natural gas pressures Event triggered high sampling rate pressure logger

Event triggered high sampling rate pressure logger Water system peak demand pressure and flow data logger

Water system peak demand pressure and flow data logger

- Detecting leaks in industrial estate water supply network

- Wireless hydraulic prop pressure testing indicator, logger & multiple sensors

- 30 inHg low relative vacuum range digital display vacuum pressure gauge and logger

- 100 mbar g low range air pressure gauge and logger with G1/4 male fitting

- 700 barg natural gas high range pressure gauge logger with 1/2 NPT male fitting

- 1000 bar PC logging pressure gauge for connecting to computer USB port

- Vacuum drying pressure data logger

- 15000 psi combined pressure gauge and logger with USB interface

- 30 mbar Intrinsically safe gas pressure data logger

- 10000 psi Digital Pressure Gauge with Memory Storage

- High temperature oven 2 bar range pressure sensor & data logger

- 15,000 psi intrinsically safe high pressure logger

Product Types

Vacuum, Suction Pressure Data Loggers, Recorders - Vacuum data loggers for recording negative suction pressure or absolute pressure below atmospheric pressure. Log and store vacuum measurements for printing test reports or analysing process trends.

Vacuum, Suction Pressure Data Loggers, Recorders - Vacuum data loggers for recording negative suction pressure or absolute pressure below atmospheric pressure. Log and store vacuum measurements for printing test reports or analysing process trends. Intrinsically Safe Pressure Data Loggers - Intrinsically safe (IS) pressure data loggers which can be used in potentially explosive environments such as oil refineries, offshore oil platforms and natural gas distribution.

Intrinsically Safe Pressure Data Loggers - Intrinsically safe (IS) pressure data loggers which can be used in potentially explosive environments such as oil refineries, offshore oil platforms and natural gas distribution. Hydraulic Testing Pressure Data Loggers - Hydraulic system & components testing pressure reading data storage logger.

Hydraulic Testing Pressure Data Loggers - Hydraulic system & components testing pressure reading data storage logger.

Product Help

Specifying pressure data logger requirements

Some questions to ask when defining the product requirements for a pressure data logger.

Operating pressure range

What is the expected highest and lowest pressure you are likely to measure?

Pressure reference

What should the pressure be referenced to, atmospheric pressure (g), absolute vacuum (abs) or another pressure (dp)?

Power supply

Do you need internal battery power or a external connection for a low or high voltage power supply?

Installation type

Where is the pressure data logger going to be installed; outside, panel mounted, cabinet mounted, or bench top?

Viewing readings and trends during logging

Do you want to view pressure readings and trends on a computer display screen whilst logging or later on after data has been saved within the logger?

Maximum number of stored pressure readings

How many pressure reading data points do you need to store between downloading data files?

Accuracy

How accurate does the pressure measurement need to be?

Resolution

How small a change in pressure do you need to distinguish?

Minimum logging rate

What will be the minimum time interval you need between saved pressure data points?

Computer interface type

How do you want to connect to a computer, USB, RS485, Ethernet, Bluetooth, mobile cellular network, or WiFi?

Pressure connection fitting

What style and size of pressure fitting is required; thread, flange or flexible tubing?

Other measurement parameters

Do you need to measure anything else, such as temperature?

Number of pressure input channels

How many pressure input channels are required to measure at the same time?

Test reports and certificates

Do you need to generate your own printed reports or certificate to document the logging results?

Exporting log data

Will you need to export the logged data to another software program in order to process the test results?

Local readout display

Do you need a local digital display built into the logger to show the actual pressure readings?

Checklist for pressure data logger requirements

Define your pressure data logger requirements using this checklist:

- Operating pressure range?

- Pressure reference?

- Power supply?

- Installation type?

- Viewing readings and trends during logging?

- Maximum number of stored pressure readings?

- Accuracy?

- Resolution?

- Minimum logging rate?

- Computer interface type?

- Pressure connection fitting?

- Other measurement parameters?

- Number of pressure input channels?

- Test reports and certificates?

- Exporting log data?

- Local readout display?