Intrinsically safe (IS) pressure data loggers which can be used in potentially explosive environments such as oil refineries, offshore oil platforms and natural gas distribution.

Battery powered data loggers for recording air or liquid pressures in hazardous zones containing flammable substances. Set up a data logging procedure for immediate, delayed or event activated recording and then download the test results to a laptop or desktop computer to analyse the results and produce graphs.

Products

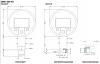

DM01 Multi-Range High Accuracy Pressure Gauge - High precision digital pressure gauge with 0.05% full scale accuracy, exchangeable pressure range modules from 100 mbar (1.5 psi) up to 400 bar (6000 psi).

DM01 Multi-Range High Accuracy Pressure Gauge - High precision digital pressure gauge with 0.05% full scale accuracy, exchangeable pressure range modules from 100 mbar (1.5 psi) up to 400 bar (6000 psi). DM01-500-HD High Range Digital Pressure Gauge - The DM01-500 HD high range pressure gauge is available in pressure ranges from 0 to 600, 1000, 1600, 2000 & 2200 bar.

DM01-500-HD High Range Digital Pressure Gauge - The DM01-500 HD high range pressure gauge is available in pressure ranges from 0 to 600, 1000, 1600, 2000 & 2200 bar.

Applications

700 barg natural gas high range pressure gauge logger with 1/2 NPT male fitting - Digital display high pressure gauge for pipe mounted use in natural gas measurement applications, capable of measuring 0 to 700 bar g pressure with 0.1% accuracy and connected using a 1/2 NPT male fitting. Also includes USB, logger, log software and cal cert.

700 barg natural gas high range pressure gauge logger with 1/2 NPT male fitting - Digital display high pressure gauge for pipe mounted use in natural gas measurement applications, capable of measuring 0 to 700 bar g pressure with 0.1% accuracy and connected using a 1/2 NPT male fitting. Also includes USB, logger, log software and cal cert. 30 mbar Intrinsically safe gas pressure data logger - Low pressure data logger with battery power, internal data storage memory & intrinsic safety approval for measuring gas pressures up to 30mb gauge.

30 mbar Intrinsically safe gas pressure data logger - Low pressure data logger with battery power, internal data storage memory & intrinsic safety approval for measuring gas pressures up to 30mb gauge. 15,000 psi intrinsically safe high pressure logger - Pressure data logger with internal battery and memory for use in oil and gas applications to measure pressures up to 15,000 psi.

15,000 psi intrinsically safe high pressure logger - Pressure data logger with internal battery and memory for use in oil and gas applications to measure pressures up to 15,000 psi. 30 ounces per square inch range pressure gauge with built-in logger - Pressure gauge with range from 0 to 30 oz/sq in, with intrinsically safe certification, which can record pressure readings

30 ounces per square inch range pressure gauge with built-in logger - Pressure gauge with range from 0 to 30 oz/sq in, with intrinsically safe certification, which can record pressure readings

6000 psi recording digital pressure gauge with intrinsic safety

6000 psi recording digital pressure gauge with intrinsic safety Ex logger for recording pressure up to 300 bar & temperature up to 40degC

Ex logger for recording pressure up to 300 bar & temperature up to 40degC Datalogging pressure gauge to use in hazardous zone 1 to measure 0 to 400 psig

Datalogging pressure gauge to use in hazardous zone 1 to measure 0 to 400 psig Ex pressure gauge and logger for recording up to 300 lbs/sq in

Ex pressure gauge and logger for recording up to 300 lbs/sq in +/-100 millibar digital manometer recorder with ATEX approval

+/-100 millibar digital manometer recorder with ATEX approval Self powered +/- 1 psi g hazardous area pressure recorder

Self powered +/- 1 psi g hazardous area pressure recorder Data logger for ATEX zone 1 area to measure up to 5000 psi

Data logger for ATEX zone 1 area to measure up to 5000 psi Portable recorder to log pressures up to 100 psi in hazardous area

Portable recorder to log pressures up to 100 psi in hazardous area

Intrinsically safe approved instrumentation can be installed in hazardous area zones and connected to other appropriate intrinsically safe equipment. Intrinsic safety is achieved by limiting the amount of electrical power that can enter the protected zone by incorporating zener diode or isolation transformer barriers, ensuring a specified surface temperature is not exceeded, and preventing electrical discharges which may otherwise ignite a potentially explosive atmosphere.

A pressure data logger is an instrument which incorporates a pressure measuring device with a data storage memory and firmware, or separate computer software and interface to facilitate the recording of pressure values. A pressure data logger can be setup by the user to commence recording at a certain time or event, at a preset sample rate. Once the pressure data logger has completed collecting data, the software can be utilised to analyze or transfer the data to a data file for export to another application program.