High precision digital pressure gauge with 0.05% full scale accuracy, exchangeable pressure range modules from 100 mbar (1.5 psi) up to 400 bar (6000 psi) gauge or absolute, in-built logging of pressure and temperature up to 600,798 values and optional ATEX intrinsic safety. Leak testing version for logging change in pressure.

Product Parameters

- Pressure Ranges: 100 mbar (1.5 psi) up to 400 bar (6000 psi) gauge or absolute, -1 to 0 bar (-14.5 psi) vacuum

- Pressure Units: bar, mbar, psi, inHg, cmHg, mmHg, hPa, kPa, MPa, mmH2O, mH2O, kg/cm²

- Accuracy: +/-0.05% FS 0.4 bar, +/-0.125% FS BSL below 0.4 bar

- Temperature Measurement Range: -10 to 55 degC

- Temperature Measurement Accuracy: +/-2 degC

- Display: Backlit LCD graphic display with pressure, temperature and time readout plus 100 segment bargraph

- Data Storage: 600,798 values maximum

- Recording Interval: 1 second minimum

- Pressure Connections: 1/2 BSP, 1/4 BSP, 1/2 NPT, 1/4 NPT and 1/2 BSP standard, flush or open port male

- Power Supply: 3 x 1.5V AA (LR6) batteries

- Environmental Protection: IP67

- Media Operating Temperature Range: -10 to +55 degC

- Media Compatibility: Stainless steel 316L pressure port and diaphragm plus FKM O ring seal

- Weight: approx. 680g

- Dimensions: 100mm diameter bezel, 148.5mm height

- Special Features: interchangeable pressure sensing modules, data logging up to 600,798 readings, data analysis software, bargraph, illuminated display, max/min peak store, stainless steel 304 display housing

- Special Options: ATEX intrinsically safe approval, flush diaphragm, pressure calibration hand pump, process connection adapters, leak testing version

Product Description

The DM 01 high precision pressure gauge provides high precision pressure measurement, multirange capability via modular sensors and data storage which makes it a versatile test tool for monitoring pressure trends or calibrating other pressure measurement devices.

The DM 01 high precision pressure gauge provides high precision pressure measurement, multirange capability via modular sensors and data storage which makes it a versatile test tool for monitoring pressure trends or calibrating other pressure measurement devices.

The graphic display of the DM01 datalogging pressure gauge includes a high resolution indication of the pressure in the middle of the display, the temperature of the pressure sensor in the top left corner and the time in top right corner of the display. At the very top of the screen is a 100 segment bargraph which shows the current pressure reading as a percentage of full scale. The soft keys for changing menu options such as pressure units are located at the bottom of the screen just above membrane keypads.

The DM01 high accuracy pressure gauge main feature is the interchangeable pressure sensor modules. All the characteristics and calibration data are stored internal to the pressure sensor module and are uploaded when plugged into the pressure gauge head.

The DM01 high accuracy pressure gauge main feature is the interchangeable pressure sensor modules. All the characteristics and calibration data are stored internal to the pressure sensor module and are uploaded when plugged into the pressure gauge head.

It is possible to use one pressure gauge head for as many pressure sensor modules as you wish. Since the pressure gauge head and the sensor modules can be supplied separately, you can add additional ranges at a later date as required.

The DM-01 pressure gauge is supplied with the ability to store up to 600,798 readings as standard, a cable to connect to a PC and some basic software to display the data on the computer.

The DM01 can be used a reference standard for use as a pressure calibrator. An optional calibration kit including hand pump, adapters, seals, test hose and service case can be supplied for use with the DM01.

Product Applications

Gas operated generator

Check the supply pressure being fed to a natural gas operated generator.

- SKU ID: s1-dm01-0015

- Part No: DM01-A2E / M0K-1002-E-B1-100-1-000 / ZUSBCD01

- Pressure Sensor Modules: 10 bar (145 psi) gauge

- Process Connection: G1/2 DIN3852 male

- Data Storage Type: Data Logging – DM01

- Digital Interface: USB Converter and PC Software

- Optional Extras: ATEX intrinsically safe approved

Flame lamination

Record data of natural gas pressure supplying a flame lamination machine.

- SKU ID: s1-dm01-0013

- Part No: DM01-A2E / M0K-4000-E-B1-N40-1-000 / ZUSBCD01

- Pressure Sensor Modules: 400 mbar (5.8 psi) gauge

- Process Connection: 1/4 NPT male

- Data Storage Type: Data Logging – DM01

- Digital Interface: USB Converter and PC Software

- Optional Extras: ATEX intrinsically safe approved

Water deluge

Measure water deluge pressure on hydrocarbon storage tanks as part of monitoring & testing the performance of a fire protection system.

- SKU ID: s1-dm01-0011

- Part No: DM01-A2E / M0K-1002-E-B1-100-1-000 / ZUSBCD01

- Pressure Sensor Modules: 10 bar (145 psi) gauge

- Process Connection: G1/2 DIN3852 male

- Optional Extras: ATEX intrinsically safe approved

- Optional Extras: USB converter and logging software

IBC hydrostatic testing

Monitor pressure for hydrostatic testing of intermediate bulk containers (IBC).

- SKU ID: s1-dm01-0009

- Part No: DM01-A21 / M0K-1002-0-B1-N40-1-000 / ZUSBCD01

- Pressure Sensor Modules: 10 bar (145 psi) gauge

- Process Connection: 1/4 NPT male

- Optional Extras: USB converter and logging software

Pipeline hydrotesting

Check for leaks in an pipeline filled with pressurized water by monitoring pressure drop over time using the in-built data logger or the stored maximum & minimum pressure reading.

- SKU ID: s1-dm01-0007

- Part No: DM01-A21 / DM01-M0L-2503-0-B1-N40-1-000 / ZUSBCD01

- Pressure Sensor Modules: 250 bar (3600 psi) absolute

- Process Connection: 1/4 NPT male

- Optional Extras: USB converter and logging software

3-15 psi pneumatic signal

Monitor the 3 to 15 psi signal used to control pneumatic control valves.

- SKU ID: s1-dm01-0004

- Part No: DM01-A2E / M0K-2501-E-B1-N40-1-000 / ZUSBCD01

- Pressure Sensor Modules: 2.5 bar (36 psi) gauge

- Process Connection: 1/4 NPT male

- Optional Extras: ATEX intrinsically safe approved

- Optional Extras: USB converter and logging software

Calibrating tank level transmitters

Check calibration of tank level transmitters with air.

- SKU ID: s1-dm01-0005

- Part No: DM01-A21 / M0K-1000-0-B2-300-1-000

- Pressure Sensor Modules: 100 mbar (1.5 psi) gauge

- Process Connection: G1/4 DIN3852 male

Product Help

Multiple pressure sensor modules and interchangeability

Can the DM01 digital pressure gauge be ordered with more than one pressure sensor and are they interchangeable, or is the pressure sensor fitted to the gauge in the factory and permanently fixed?

Yes the pressure sensors are interchangeable, all the calibration data is stored in the pressure sensor module, so that you can plug-in any pressure sensor module and it will be ready to use.

You can order the DM01 with more than one sensor, and also add more pressure sensor modules at a later date, if you want to expand the pressure range capability of the DM01.

Logger sampling rate

What is the sampling rate for the logging function?

There are 3 settings to choose from: 1, 2 or 50 measurements per second which you can set up in the display.

Recording when pressure is within parameters

Could we adjust the parameters so the gauge will only record the pressure when over a set figure say 100 Bar?

Unfortunately not, it will data log as soon as you activate it in the menu and continue to log at the specified intervals until it is stopped.

Lowest vacuum measurement range

We have a vacuum chamber where we will be measuring a rough vacuum. It doesn’t need to be very accurate. What is the lowest range possible with this gauge? It would be great to have 10-3 mbar but didn’t think it would be possible with this sort of gauge.

The lowest absolute range for the DM01 is 0 to 400 mbar absolute. We would suggest the Baroli 05 as an alternative to the DM01, which has a lower grade accuracy, lower in cost, and the lowest possible range is 0.6 bar absolute,

These types of pressure gauge measure over a linear range which quickly diminishes in accuracy at lower pressures which are an order of magnitude smaller than the full scale range. Also there is a limit to how effective diaphragm type pressure gauges can measure, due to increased sensitivity to temperature, vibration and mechanical constraints of the sensing materials. Therefore it is not possible to produce ranges that go much lower than a few hundred millibar. As you point out, a roughing vacuum such as 10-3 mbar is too low for a typical pressure gauge, and instead a different type of gauge has to be used which are non-linear such as pirani gauges.

Adding comments to pressure readings

Does the software allow you to enter a comment next to each pressure reading?

No, annotation can only be done when you have exported the data to csv/xls etc.

Comparing historical log of 2 pressures

I’m looking to log the air feed pressure to an air bearing in a high speed air bearing turbine. If an air bearing failure occurs, a time stamped historical log could be compared against a second system that monitors in the same way the drive air pressure of the turbine. The typical air bearing pressures are 80…100 psi and drive air pressures are 20…100 psi.

We would suggest 2 x DM01, synchronise the clock of each, and then combined the stored data when exporting to a spreadsheet to compare the two sets of readings.

- SKU ID: s1-dm01-0022

- Part No: DM01-A21 / M0K-1002-0-B1-N40-1-000 / ZUSBCD01

- Pressure Sensor Modules: 10 bar (145 psi) gauge

- Process Connection: 1/4 NPT male

- Data Storage Type: Data Logging – DM01

- Digital Interface: USB Converter and PC Software

PDF data export

What output would we get from the software? Would we be able to export to a PDF?

The data can be exported to csv / xls and from there you can print to PDF

Vacuum recorder 0-30 inHg

I’m looking for a vacuum recorder to measure over the range of 0 to 30 inHg?

The DM 01 has two ranges for measuring over the vacuum range:

0 to -1 bar gauge

Negative gauge reference or suction pressure range:

- SKU ID: s1-dm01-0018

- Part No: DM01-A21 / M0K-X102-0-B1-N40-1-000 / ZUSBCD01

- Pressure Sensor Modules: 0 to -1 bar (-14.5 psi) gauge

- Process Connection: 1/4 NPT male

- Data Storage Type: Data Logging – DM01

- Digital Interface: USB Converter and PC Software

0 to 1 bar absolute

Absolute or perfect vacuum reference pressure range:

- SKU ID: s1-dm01-0019

- Part No: DM01-A21 / DM01-M0L-1602-0-B1-N40-1-000 / ZUSBCD01

- Pressure Sensor Modules: 0 to +1 bar (14.5 psi) absolute

- Process Connection: 1/4 NPT male

- Data Storage Type: Data Logging – DM01

- Digital Interface: USB Converter and PC Software

Change recording interval

Is it possible to change the intervals between each recording?

Yes, you can select if you want to data log in hours, mins, seconds and define the number.

Confirming reduced pressure during the night

We are running experiments overnight and currently have a pressure gauge to monitor the pressures between 10-60 psi, and we believe that we are getting reduced pressure at certain times during the night, so we want to confirm when and if these are happening. What would you suggest?

The DM01 includes the capability to log up to 600,798 pressure values with a minimum interval of 1 second. Using the optional USB interface and PC software you will be able to upload the results to a computer to transfer the data into a spreadsheet. The standard 6 bar range can display and measure up to 87 psi.

- SKU ID: s1-dm01-0017

- Part No: DM01-A21 / M0K-6001-0-B1-100-1-000 / ZUSBCD01

- Pressure Sensor Modules: 6 bar (87 psi) gauge

- Process Connection: G1/2 DIN3852 male

- Data Storage Type: Data Logging – DM01

- Digital Interface: USB Converter and PC Software

Vehicle coil spring tester up to 3000 psi

I’m looking for a digital pressure gauge to incorporate into a vehicle coil spring tester to measure the hydraulic oil pressure up to 3000 psi, to determine the weight a spring will hold at a given height. I will need to upload the test results to a laptop to be able to create graphs.

A 250 bar range DM01 is equivalent to 3,625 psi, so this would be the closest range suitable. The DM01 has a built-in datalogger and an optional USB cable and software can be provided to allow you to upload the stored results to your laptop. Once uploaded you can transfer the data to a spreadsheet to combine with other data and create graphs to display the test results.

- SKU ID: s1-dm01-0016

- Part No: DM01-A21 / M0K-2503-0-B1-300-1-000 / ZUSBCD01

- Pressure Sensor Modules: 250 bar (3600 psi) gauge

- Process Connection: G1/4 DIN3852 male

- Data Storage Type: Data Logging – DM01

- Digital Interface: USB Converter and PC Software

Zone 1 ATEX & display pressure/temperature

I am looking for a ATEX, zone 1 rated, battery powered gauge which will display pressure and temperature to replace a standard dial pressure gauge.

I am looking for a ATEX, zone 1 rated, battery powered gauge which will display pressure and temperature to replace a standard dial pressure gauge.

The DM01 is ATEX approved to zone 1: II 2G Ex ia IIC T4 Gb, and can display both pressure & temperature at the same time.

Boiler trip out

We are looking to obtain a data-logger which we can connect to a natural gas supply pipework which serves a number of boilers in our building. We believe the incoming gas supply pressure is changing and causing the boilers to trip out when it dips below the low pressure threshold. The pressures we need to monitor should be between 0 and 5 psig.

The DM 01 includes a built-in data logger for storing up to 600,798 values, and we would suggest a standard 400 mbar range which will allow you to display and record natural gas pressure values up to up to 5.8 psi.

- SKU ID: s1-dm01-0014

- Part No: DM01-A2E / M0K-4000-E-B1-N40-1-000 / ZUSBCD01

- Pressure Sensor Modules: 400 mbar (5.8 psi) gauge

- Process Connection: 1/4 NPT male

- Data Storage Type: Data Logging – DM01

- Digital Interface: USB Converter and PC Software

- Optional Extras: ATEX intrinsically safe approved

DL 01 & DM 01 comparison

What is the difference between the DL 01 and DMo1 digital pressure gauge?

DM01 is a digital pressure gauge for general high accuracy measurement & calibration purposes. The front panel user interface allows pressure values to be displayed and recorded.

DL01 is a digital pressure gauge for leakage detection. The front panel user interface allows pressure differences measured during a leak test to be displayed and recorded.

1/4 NPT gauge with download

We are looking for a 1/4 inch NPT gauge and need the device to monitor water pressure and record for down load. The device must be able to monitor pressure up to 200psi which should be readable as well as downloadable.

You can display the pressure in psi on the front panel display and download stored readings to a PC using the software and USB interface included in the spec below:

- SKU ID: s1-dm01-0012

- Part No: DM01-A21 / M0K-1602-0-B1-N40-1-000 / ZUSBCD01

- Pressure Sensor Modules: 16 bar (230 psi) gauge

- Process Connection: 1/4 NPT male

- Optional Extras: USB converter and logging software

Manual 50 ton ram bench press gauge

I’m looking to upgrade to digital, and want to replace a 0-50 ton ram force dial gauge on a manual 6.5″ ram bench press, can you recommend?

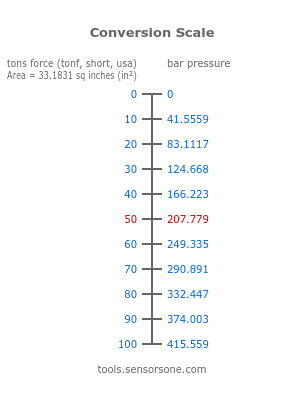

You will need a pressure gauge that can be custom scaled to display the reading in force units rather than pressure units. To determine the pressure range required you can convert the ram diameter of 6.5 inches to area, and then convert the force range of 50 tons and ram area to pressure and the graphic below shows the resulting conversion.

Then once you know what pressure range is required you can choose the closest upper range to 207.779 bar which is 250 bar, and then set up a special unit using the optional configuration software which will allow you to read in tons.

- SKU ID: s1-dm01-0010

- Part No: DM01-A21 / M0K-2503-0-B1-N40-1-000 / ZUSBCD01

- Pressure Sensor Modules: 250 bar (3600 psi) gauge

- Process Connection: 1/4 NPT male

- Optional Extras: USB converter and logging software

Pressure fluctuation testing up to 200 psi

I am looking for a data recorder which can be utilized for hydrostatic or pressure fluctuation testing within a municipal water mains. Also to hydrostatic test a fire sprinkler protection system and monitoring up to 200 psi max standard pressure.

The DM01 includes the capability to store up to 600,798 readings and transfer the data via the optional USB converter cable & PC logging software.

- SKU ID: s1-dm01-0006

- Part No: DM01-A21 / M0K-1602-0-B1-N40_1-000 / ZUSBCD01

- Pressure Sensor Modules: 16 bar (230 psi) gauge

- Process Connection: 1/4 NPT male

- Optional Extras: USB converter and logging software

Accuracy over 50 to 150 mmHg

I want to measure over 50 to 150 mmHg, what will be the accuracy of readings over this range?

For the closest standard range of 0 to 250 mbar (187.5 mmHg), the accuracy will be 0.094 mmHg.

Dynamic testing over a 3 weeks period

I am planning to perform dynamic tests over 3 weeks and need therefore to record the pressure during this time. Is the gauge able with the according software to record it over this time span?

Yes, if you have the USB and software option, you will be able to log data over a 3 week period and upload results to the PC software.

Calibration certificate validity

How long does the calibration certificate last for the DM01 Multi-Range High Accuracy Pressure Gauge?

A cal cert is a verification of the accuracy of a instrument on the day tested, and a time period for validity of the cal cert is not usually specified.

The DM01 product data sheet states the following:

Long term stability ≤ ± 0.1 % FSO / year at reference conditions

Therefore if your measurements can tolerate an additional error of 0.1% over a period of 1 year, an annual re-calibration should suffice.

24 hour vacuum recorder

I need a vacuum recorder that records vacuum for at least 24 hours?

You can store up to 600,798 values in the DM 01 memory, so you will be able to store 1 reading approximately every 15 seconds without exceed the memory capacity over a 24 hour period.

- SKU ID: s1-dm01-0020

- Part No: DM01-A21 / M0K-X102-0-B1-N40-1-000 / ZUSBCD01

- Pressure Sensor Modules: 0 to -1 bar (-14.5 psi) gauge

- Process Connection: 1/4 NPT male

- Data Storage Type: Data Logging – DM01

- Digital Interface: USB Converter and PC Software

inH2O units

How do you read pressure in inches of water column with the DM01 pressure gauge?

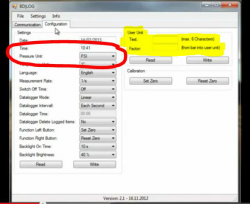

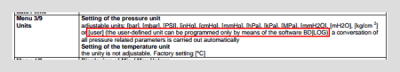

The DM01 does not come with the inch of water (inH2O, inWG, inWC) pressure unit as standard. However it is possible to configure any pressure unit of your own via the PC configuration software which is provided as standard along with the USB interface cable.

You will need to know the conversion factor to convert from bar to inH2O. We use 100,000/249.08891 = 401.463076

If necessary the DM01 can also be set-up in the factory before delivery to include the inch of water gauge pressure unit.

6,000 & 10,000 kPa reading resolution

What is the reading resolution for a 60 bar and 100 bar range DM01 pressure gauge with the kilopascal (kPa) unit selected?

A 0 to 60 bar range DM01 will correspond to 0 to 6,000.0 kPa, so the resolution will be 0.1 kPa.

A 0 to 100 bar range DM01 will correspond to 0 to 10,000 kPA, so the resolution will be 1 kPa.

Measurement unit is not included

I would like to use the DM01 high accuracy pressure gauge, but it does not have the pressure unit I need, is there an equivalent gauge which has more units?

The DM-01 pressure gauge has the option to set a user defined unit via the PC software provided as standard.

The DM-01 can also be programmed in the factory prior to delivery to include the required pressure unit.

PC real time pressure logging

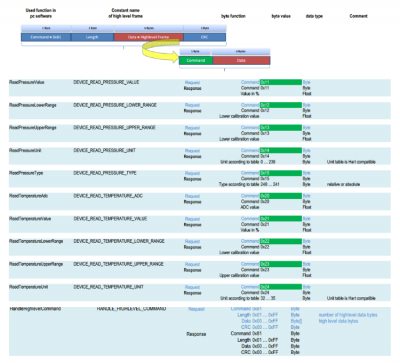

Can you live log real time data to a PC using the serial interface, or is it just upload only from the DM01 pressure logger?

Yes, it is possible to communicate with DM01 via serial interface. You have to install the “virtual com port driver” and use this port for communication.

Use the following parameters:

Baudrate: 38400 baud Parity: none Startbit: one Stopbit: one Databits: 8 CRC: XOR over all previous databytes Commands: See attached pdf files

Accuracy for calibration use

What is the accuracy of the DM01 pressure test gauge for calibration purposes?

0.1% full scale including the temperature errors from 0 to 50 degrees Celsius (32 to 122 degrees Fahrenheit). N.B. The accuracy quoted on the product data sheet is 0.05% BFSL, which is based on the best straight line method and not an indication of true accuracy, so this should be ignored if using the gauge for calibration purposes.

Minimum time between recording readings

What is the minimum interval time that can be set between recorded data points on the DM 01 precision digital gauge?

The minimum possible time to set between recordings is 1 second.

How many readings can be stored in logger

The maximum number of stored reading is 600,798 for the DM-01 multi-range pressure datalogger, but is that 600,798 pressure readings + 600,798 temperature readings or is the memory split in half with 300,399 for pressure and 300,399 for temperature?

1 stored reading consists of:

- date

- time

- pressure value

- temperature value

Therefore you can store 600,798 pressure and 600,798 temperature readings.

Batteries to install

Does the battery used with the DM01 multi-range digital pressure logger need to be Alkaline?

No, other types can be used as long as they are Mignon/AA type batteries.

R407F refrigerant

I’m looking for a gauge suitable for use on refrigerant, we have systems running on R407F up to 500 psi that we need to log.

This DM01 spec has an all welded wetted parts so only stainless steel 316L will be exposed to the refrigerant:

- SKU ID: s1-dm01-0001

- Sensor Module 1: 40 bar (580 psi) gauge

- Process Connection: G1/4 EN837 internal thread (all welded)

- Data Logging: USB cable and data analysis software

Vacuum curing

We need a way of recording the vacuum pull, while curing a panel in room temperature with a vacuumed bag assembly, what DM01 spec would you suggest?

A DM01 with the data logging package option and a 0 to -1 bar vacuum range is what we would suggest for this application:

- SKU ID: s1-dm01-0002

- Pressure Sensor Modules: 0 to -1 bar (-14.5 psi) gauge

- Process Connection: 1/4 NPT male

- Optional Extras: USB converter and logging software

Water heating system pressure

Please could you advise whether the DM01 data logger is suitable for water pressure. The use will be for monitoring the pressure in heating systems in a large building complex. The water temperature will be a maximum of 85 deg C, and the pressure that is to be monitored is in the range from 1 bar gauge to 8 bar gauge.

Yes you can use the DMO01 to measure water pressure, but please bear in mind that the operating limit is 55 degC, although a short length of pipe between the logger and the heating system should be sufficient to cool the water down to 55 degC at the measurement point of the logger.

- SKU ID: s1-dm01-0003

- Pressure Sensor Modules: 10 bar (145 psi) gauge

- Process Connection: G1/2 DIN3852 male

- Optional Extras: USB converter and logging software

Maximum process temperature

What is the highest temperature that the DM 01 can be used with?

The operational and measurement range are both limited to 55°C/131°F.

Transfer data in .csv file format

I’m interested in the more advanced software option to download charts and make printouts. How would you create a .csv file for example?

If you stop measuring by changing the logging mode from ‘linear’ to ‘off’, you will then be able download the measurement values as a .csv file.

Related Documents

Specification data sheets

Request Product Price

Please select the options you require for the DM01 Multi-Range High Accuracy Pressure Gauge in your application and request a quote.

"*" indicates required fields