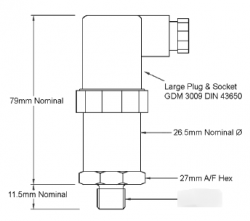

For most general purpose applications the DIN43650 plug and socket connector is one of the most widely specified for industrial pressure transmitters. The DIN 43650 plug is very low cost and a IP65 ingress protection rating can be achieved if it is joined correctly to a cable. However care must be taken not to block the vented gauge reference of the pressure transmitter whilst seeking to achieve an IP 65 seal.

For most general purpose applications the DIN43650 plug and socket connector is one of the most widely specified for industrial pressure transmitters. The DIN 43650 plug is very low cost and a IP65 ingress protection rating can be achieved if it is joined correctly to a cable. However care must be taken not to block the vented gauge reference of the pressure transmitter whilst seeking to achieve an IP 65 seal.

The IP65 rating is only achieved if a cable is correctly sealed with the provided gland nut. However, it is important to ensure that the cable is not restricted from breathing when sealing the cable on a low range gauge pressure transmitter. Most pressure transmitters with a range up to 60 bar gauge require a vent to ensure that atmospheric pressure is applied to the reverse side of the pressure sensing diaphragm. To be absolutely sure a pressure transmitter is properly vented it is best to use a cable that incorporates a vent tube.

Some manufacturers will use a special DIN plug that incorporates a side vent which allows air in but keeps moisture out. However it is not always clear in the manufacturer’s literature that this side vent is fitted and also it is very easy to replace the DIN plug at a later date with a variation that does not include a custom side vent which could compromise the vent path.

It is possible to vent between the cores of the cable on higher pressure ranges above a few bar but a vent path cannot be guaranteed especially if there is a tight seal around the gland seal or condensation inside the cable. Low pressure ranges are particular sensitive to atmospheric pressure changes and a vent path that is blocked or is not very responsive could lead to inaccurate pressure readings.

Featured vented gauge pressure transmitter products

Low operating temperature plus/minus 1 psi pressure transmitter - Reliable pressure measurements down to -40°C. Ideal for low range applications with a -1 to +1 psi gauge range.

Low operating temperature plus/minus 1 psi pressure transmitter - Reliable pressure measurements down to -40°C. Ideal for low range applications with a -1 to +1 psi gauge range. SIL2 approved 10 bar pressure transducer with 4 to 20 mA output - Pressure transducer with SIL 2 approved electronics that provide a 4-20mA output over a 0-10bar working range.

SIL2 approved 10 bar pressure transducer with 4 to 20 mA output - Pressure transducer with SIL 2 approved electronics that provide a 4-20mA output over a 0-10bar working range.

Related Help Guides

- Choosing PVC, PUR, FEP and TPE cable types

- Determining the signal cable length of a suspended liquid level transducer

- Improve the electrical termination of vented submersible pressure sensors

Related Application Questions and Answers

Contact us about this IP65 sealing a vented gauge pressure transmitter with a DIN plug page to request more information, or to discuss your application requirements.