Flush diaphragm pressure transmitters with 4 to 20mA current loop signal output with exposed diaphragms for measuring viscous media or substances which require hygienic or sanitary compatibility.

Select flush diaphragm pressure transmitters with a screw-in, tri-clamp, dairy or flange mount fitting for installations where the media may clog conventional process fittings with internal voids which impede operation, or where a high level of cleanliness is required to prevent contamination of the product being processed.

Pressure transmitters with open flush diaphragms suitable for use with highly viscous media such as plastics, paper pulp, bitumen, sewage, paint and adhesives.

Products

x|act i Rangeable Flush Pressure Transmitter with LCD Readout - Rangeable Pressure Transmitter with a hygienic all stainless steel construction with LCD digital readout display and optional HART communications.

x|act i Rangeable Flush Pressure Transmitter with LCD Readout - Rangeable Pressure Transmitter with a hygienic all stainless steel construction with LCD digital readout display and optional HART communications. LMK 487 Submersible Ballast Tank and Draught Level Pressure Transmitter - A 22mm diameter titanium body seawater depth and level probe with a 4-20mA output with Lloyds and DNV-GL ship approval, for monitoring the quantity of ballast or the draft of a ship’s hull.

LMK 487 Submersible Ballast Tank and Draught Level Pressure Transmitter - A 22mm diameter titanium body seawater depth and level probe with a 4-20mA output with Lloyds and DNV-GL ship approval, for monitoring the quantity of ballast or the draft of a ship’s hull.

TPFADA Flush Diaphragm Pressure Transmitter

TPFADA Flush Diaphragm Pressure Transmitter XMPi Process Plant Gauge and Absolute Pressure Transmitter

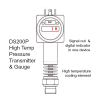

XMPi Process Plant Gauge and Absolute Pressure Transmitter DS200P Sanitary Low Range Pressure Gauge, Switch and Sensor

DS200P Sanitary Low Range Pressure Gauge, Switch and Sensor DS201P High Range Flush Pressure Gauge, Switch and Sensor

DS201P High Range Flush Pressure Gauge, Switch and Sensor

Applications

Diaphragm sealed high temperature pressure transmitter for -1 to 25 kg/cm² - Diaphragm sealed pressure transmitter for measuring over -1 to 25 kg/cm² on liquid with a flush type diaphragm up to a temperature of 190°C.

Diaphragm sealed high temperature pressure transmitter for -1 to 25 kg/cm² - Diaphragm sealed pressure transmitter for measuring over -1 to 25 kg/cm² on liquid with a flush type diaphragm up to a temperature of 190°C. Food processing freshwater transfer pump 4 barg 4-20mA pressure sensor - A hygienic stainless steel flush diaphragm gauge pressure sensor for food processing pump transfer system to measure pressure of freshwater over a range of 0 to 4 bar g from the tri-clamp process connection, and sending the corresponding 4-20mA signal through the M12 connector electrical connection.

Food processing freshwater transfer pump 4 barg 4-20mA pressure sensor - A hygienic stainless steel flush diaphragm gauge pressure sensor for food processing pump transfer system to measure pressure of freshwater over a range of 0 to 4 bar g from the tri-clamp process connection, and sending the corresponding 4-20mA signal through the M12 connector electrical connection.

6 bar absolute range 4-20mA output high temperature epoxy resin pressure sensor for research use

6 bar absolute range 4-20mA output high temperature epoxy resin pressure sensor for research use Water reclamation system 6 bar range pressure transmitter for marine use

Water reclamation system 6 bar range pressure transmitter for marine use Flush mountable vacuum transmitter

Flush mountable vacuum transmitter G1/2 flush 60 psig pressure transmitter for thick liquids in Ex zones

G1/2 flush 60 psig pressure transmitter for thick liquids in Ex zones

- 1000 mbar vacuum transmitter for use with waste toner dust

- 50 kPa negative gauge vacuum transmitter for Milk

- 10 psi g range flush diaphragm stainless steel 316L pressure transmitter

- Ranges below 60 bar no longer available for DMK331P

- Powder filter blockage monitoring pressure transmitter

- Submersible sensor for measuring sludge pressure in pipe