Transducers with and without signal conditioning with flexible specifications for adapting to different OEM design requirements.

Products

IMP Industrial Pressure Sensor - The IMP industrial pressure sensor, has a piezo‐resisitive ceramic pressure sensor giving it excellent media compatibility

IMP Industrial Pressure Sensor - The IMP industrial pressure sensor, has a piezo‐resisitive ceramic pressure sensor giving it excellent media compatibility IMP Low Cost Pressure Sensor - Versatile low price pressure sensor with a wide selection of electrical and mechanical options for customisation.

IMP Low Cost Pressure Sensor - Versatile low price pressure sensor with a wide selection of electrical and mechanical options for customisation.

IMPLR Low Range All Stainless Steel OEM Pressure Sensor

IMPLR Low Range All Stainless Steel OEM Pressure Sensor IMSL IP68 Stainless Steel 316L Hydrostatic Pressure Sensor

IMSL IP68 Stainless Steel 316L Hydrostatic Pressure Sensor Chemical Resistant Pressure Sensor Elements for Electronic Devices & Embedded Product Design & Development

Chemical Resistant Pressure Sensor Elements for Electronic Devices & Embedded Product Design & Development 18.605 G Low Cost Submersible Diesel Fuel and Water Tank Level Sensor

18.605 G Low Cost Submersible Diesel Fuel and Water Tank Level Sensor

Applications

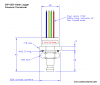

30 barg 1-5Vdc output saltwater pressure sensor for jockey fire fighting pump use - A salt water pressure sensor for flow monitoring use to measure pressure of saltwater from a jockey fire fighting pump over a range of 0 to 30 bar g from the 1/4 NPT male process connection, and sending the corresponding 1-5Vdc signal through the DIN plug electrical connection.

30 barg 1-5Vdc output saltwater pressure sensor for jockey fire fighting pump use - A salt water pressure sensor for flow monitoring use to measure pressure of saltwater from a jockey fire fighting pump over a range of 0 to 30 bar g from the 1/4 NPT male process connection, and sending the corresponding 1-5Vdc signal through the DIN plug electrical connection. 800mbar absolute range 4-20mA output high temperature protected OEM pressure sensor - High temperature protected OEM stainless steel diaphragm pressure sensor with semiconductor strain gauges for measuring over a 0 to 800 mbar absolute pressure range and generating a 4 to 20 milliamps output signal.

800mbar absolute range 4-20mA output high temperature protected OEM pressure sensor - High temperature protected OEM stainless steel diaphragm pressure sensor with semiconductor strain gauges for measuring over a 0 to 800 mbar absolute pressure range and generating a 4 to 20 milliamps output signal.

-5 to +5 psi g low compound range 4 to 20 mA output OEM pressure sensor

-5 to +5 psi g low compound range 4 to 20 mA output OEM pressure sensor 10000 psig range 4-20mA output OEM high range pressure sensor

10000 psig range 4-20mA output OEM high range pressure sensor -20 to 20 inH2O g compound range 0-10Vdc output air pressure sensor for oem use

-20 to 20 inH2O g compound range 0-10Vdc output air pressure sensor for oem use 5000 psig range 5Vdc supply with 0.5-4.5Vdc output OEM pressure sensor

5000 psig range 5Vdc supply with 0.5-4.5Vdc output OEM pressure sensor

- 75bar abs RS485 engine oil pressure sensor for power generation oem use

- Low cost, upstream/downstream, 5m range, fresh-water, weir level sensor

- 3 metre / 10 foot fresh water level transmitter for OEM system integration

- 750-1250mb absolute range OEM barometric pressure transmitter

- 40 bar g refrigerant pressure transducer for automotive environment

- R134A Coolant Pressure Transducer For Automotive Air Conditioning

Product Types

OEM Design Submersible Sensor and Instrument Probes - Customisable low cost submersible probes for OEM manufacturers of data-logging and telemetry equipment.

OEM Design Submersible Sensor and Instrument Probes - Customisable low cost submersible probes for OEM manufacturers of data-logging and telemetry equipment. OEM Millivolt Output Pressure Transducers - OEM pressure transducer with strain gauge bridge output signal for incorporating into OEM instrumentation design for easy adaption into your own custom mechanical configuration and electrical interface.

OEM Millivolt Output Pressure Transducers - OEM pressure transducer with strain gauge bridge output signal for incorporating into OEM instrumentation design for easy adaption into your own custom mechanical configuration and electrical interface.