This guide will help you choose a digital pressure sensor for your application and explain the benefits of using a digital interface to transmit pressure readings.

This guide will help you choose a digital pressure sensor for your application and explain the benefits of using a digital interface to transmit pressure readings.

There are many types of digital signal such as RS485, RS232, Modbus RTU, USB, SDI-12, I²C & IO-Link, but they all fundamentally transfer pressure readings without any loss of accuracy, and are the preferred type of pressure sensor for measuring pressures in calibration & test laboratories.

Products

Select a type of digital pressure sensor from the list below to view product choices and download product information or request a price quotation.

RS485 Serial Interface Pressure Sensors

RS485 Serial Interface Pressure Sensors RS232 Serial Interface Pressure Sensors

RS232 Serial Interface Pressure Sensors Pressure Sensors for Data Logging with a Computer

Pressure Sensors for Data Logging with a Computer USB Pressure Sensors

USB Pressure Sensors Modbus Communications Protocol Pressure Sensors

Modbus Communications Protocol Pressure Sensors

Advantages of using digital pressure sensors

For the highest possible pressure sensor accuracy you will need an output signal which is not easily corrupted and has a very high resolution.

Reduce Signal Losses & Interference

Digital output signals do not suffer from signal losses or interference like analogue ones do, either the complete signal gets through as originally transmitted from the pressure sensor or none at all.

Digital output signals do not suffer from signal losses or interference like analogue ones do, either the complete signal gets through as originally transmitted from the pressure sensor or none at all.

In order to achieve a high resolution on the output signal a relatively powerful analogue to digital converter is needed of at least 16 bit resolution to achieve precision levels better than 0.01% full scale.

Reduce Analogue to Digital Conversion Errors

Also there is no need to convert a digital signal to analogue at any stage between the pressure sensor and the display or logging instrumentation since it can be easily interfaced to a computer or data acquisition card via a digital connection.

Also there is no need to convert a digital signal to analogue at any stage between the pressure sensor and the display or logging instrumentation since it can be easily interfaced to a computer or data acquisition card via a digital connection.

Digital Error Compensation

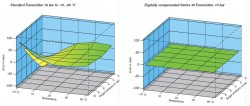

Another benefit of digital output signals is that the microprocessor inside the digital pressure sensor can also be used to digitally characterise the pressure sensor over many pressure and temperature points virtually eliminating all linearity errors.

Another benefit of digital output signals is that the microprocessor inside the digital pressure sensor can also be used to digitally characterise the pressure sensor over many pressure and temperature points virtually eliminating all linearity errors.

Exploit Repeatable & Stable Sensor Technology

However the ultimate accuracy of a digital pressure sensor is always going to be limited by the hysteresis and repeatability of the sensor technology utilised. Hysteresis and repeatability factors are very unpredictable and cannot be characterised easily.

However the ultimate accuracy of a digital pressure sensor is always going to be limited by the hysteresis and repeatability of the sensor technology utilised. Hysteresis and repeatability factors are very unpredictable and cannot be characterised easily.

So a digital output has the potential to provide the most accurate signal for a particular type of pressure sensor but it has to be used in conjunction with stable sensing technology which has naturally low hysteresis and repeatability characteristics for it to be truly accurate over its operational life.

Direct Computer Interfacing & Software Monitoring

RS485 is the most used interface for general applications and manufacturers will often supply desktop software for communicating with the digital pressure sensor via RS232 or USB converter boxes.

RS485 is the most used interface for general applications and manufacturers will often supply desktop software for communicating with the digital pressure sensor via RS232 or USB converter boxes.

Select a digital pressure sensor for your application

Find a pressure sensor with a digital interface for connecting to a digital device or computer.

If you would like us to select a pressure transmitter for you, then please use this form to specify your requirements.

Digital Interface Type

Choose a digital interface type to select a digital pressure sensor.

Pressure Range Type

Pick the type of pressure range you wish to measure digitally.

- Low pressure

- High pressure

- Differential pressure

- Hydrostatic pressure

- Barometric pressure

- Absolute pressure