High precision differential pressure transducer with an accuracy of 0.1% full scale including temperature errors over +10 to 40 deg C. Available in pressure ranges from 0.3 to 30 bar differential with a RS485 digital interface as standard plus an optional USB or RS232 converter cable for connecting to a desktop or laptop computer.

Product Parameters

- Pressure Ranges: from 0 to 0.3 up to 0 to 30 bar (15-450 psi) diff

- Accuracy: ±0.05%FS over +10 to +40 degC and ±0.1%FS over -10 to +80 degC

- Output Signal: USB, RS232 or RS485 digital interface for pressure, temperature and programming

- Electrical Connections: IP65, IP68 integral cable or Binder plug

- Pressure Connections: G1/4 BSP or 1/4 NPT female thread

- Weight: 500g

- Special Features: Connect up to 16 digital pressure transducers on one serial bus interface, log pressure and temperature readings via supplied software

- Special Options: USB or RS232 data interface cable and PC software

Product Description

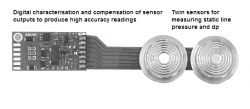

The PD33X differential digital pressure sensor incorporates semiconductor strain gauge sensing technology and digital compensation techniques to produce a highly precise pressure transducer over a wide temperature range.

The optional USB or RS232 interface cable enables the PD33X digital differential pressure transducer to be used with the prog30 instrument configuration software and the read30 data reading software. The live pressure output signal can be read or a data logging procedure can be configured for recording pressure data at timed intervals. All data can be displayed in the form of graphs and printed out if necessary.

The PD33X differential digital pressure sensor also incorporates a temperature sensor which is located very close to the diaphragm in contact with the media. This temperature sensor is used to digitally correct the pressure transducer at different temperatures and it is also provided as an output signal via the RS485 interface.

Product Applications

Water system pre-filter

Measure the difference in pressure between pre-filter inlet and outlet for a water system.

- SKU ID: s1-pd33x-0002

- Pressure Range: 30 bar diff

- Electrical Connection: 5 pin Binder connector (std)

- Length of Cable (metres) if required:

- Pressure Connection: 1/4 NPT female

- Digital Communication: USB data cable and software

- Compensated Temperature Range: -10 to +80 DegC (std)

- Wetted Parts: Stainless steel 316L and Viton (std)

Product Tutorial

Product Help

Measuring line pressure and differential pressure

Is it possible to readout the line pressure from the PD33x digital dp sensor?

You cannot read line pressure with the PD33X but you can read the pressure from each pressure port with the PD39X digital dp sensor. The PD39X has two absolute sensors inside, one for the positive and one for the negative side. The line pressure can be monitored on both sides and the differential pressure is determined by subtracting the two readings. However measurement of the line pressure is only possible with the digital interface.

1 bar range accuracy & cal points

I am interested in a PD-33X/0-1bar/4-20mA+RS485, but I need a certificate of calibration of each one, and the maximum error of the pressure measurement must be less than 0.1% F.S., the points of calibration must include 0, 468, 537, 738 mbar?

The accuracy is 0.1% full scale for the RS485 and 0.15% full scale for the 4-20mA including thermal errors over -10 to +80°C.

If you will be operating over a narrower temperature range then the PD33X specification is 0.05% full scale for RS485 and 0.1% full scale for 4-20mA over 10 to 40 degC.

The standard calibration report shows performance at 6 points over 0 to 1 bar range, 0, 200, 400, 600, 800, 1000 mbar, and this is repeated at 4 different temperatures -10, 25, 50 and 80°C for a -10 to +80°C compensated range.

High resolution measurement of pressure drop along a pipe

I need to make a high resolution measurement of the pressure drop in a pipe that could have a pressure in the range of between 30 and 150 bar. I need to measure the variation for example from 40.999 to 50.000 psi. Can you suggest any equipment able to measure in these conditions. If not what would be the minimum significant figure that could be achieved?

The best measurement resolution achievable with the PD33X is 0.002% full scale via the RS485 output which can be converted to USB or RS232.

The PD33X has a 16 bit ADC, which will provide a resolution of approximately 20 ppm. The resolution of the following standard ranges is:

- 10 bar range (~150psi) should provide a 0.003 psi resolution

- 3 bar range (~45 psi) should provide a 0.0009 psi resolution

The specification required is:

- SKU ID: s1-pd33x-0001

- Pressure Range: 10 bar diff

- Static Line Pressure: 200 bar max (must be on both sides at all times)

- Electrical Connection: 5 pin Binder connector

- Pressure Connection: 1/4 NPT female

- Digital Communication: USB data cable and software

- Compensated Temperature Range: -10 to +80 DegC

- Wetted Parts: Stainless steel 316L and Viton

Single RS485 bus for 7 sensors

Can we use the same RS485 bus to connect 7 sensors?

Yes you can join 7 RS485 connections (RS485A & B) together by connecting all the RS485A together and likewise for the RS485B connection.

Related Documents

Specification data sheet

Request Product Price

Please select the options you require for the PD33X Digital Differential Pressure Sensor in your application and request a quote.

"*" indicates required fields