Pressure gauges that combine precise local pressure indication with versatile analog output signals, ideal for industrial automation, process monitoring, and data acquisition.

Analog output pressure gauges offer a dual functionality solution for applications requiring both immediate local pressure indication and the transmission of pressure data to external control or monitoring systems. These instruments typically combine a high-visibility digital display (LED or LCD) for on-the-spot readings with an industry-standard analog output, such as a 4 to 20mA current loop or a 0 to 10Vdc voltage signal, enabling seamless integration with PLCs, SCADA systems, and other process automation hardware. This dual capability makes them invaluable for process engineers, instrument technicians, and design engineers seeking precise, reliable, and versatile pressure measurement in industrial, manufacturing, and research settings.

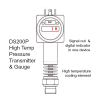

16 bar, 200°C steam pressure transmitter and gauge - Combined pressure transmitter and indicator in one package with the option for use with high temperature media such as steam at 200°C

16 bar, 200°C steam pressure transmitter and gauge - Combined pressure transmitter and indicator in one package with the option for use with high temperature media such as steam at 200°C Data acquisition module 0-10Vdc output pressure gauge - DS200 has an in-built pressure gauge and a 0-10 volt dc analogue signal output which you can feed into a data acquisition module.

Data acquisition module 0-10Vdc output pressure gauge - DS200 has an in-built pressure gauge and a 0-10 volt dc analogue signal output which you can feed into a data acquisition module.

DS200P Sanitary Low Range Pressure Gauge, Switch and Sensor

DS200P Sanitary Low Range Pressure Gauge, Switch and Sensor LEO3 Current or Digital Output Pressure Gauge

LEO3 Current or Digital Output Pressure Gauge DS210 Combined Low Pressure Switch, Indicator and Sensor

DS210 Combined Low Pressure Switch, Indicator and Sensor DS201 Combined Pressure Sensor, Display and Switch

DS201 Combined Pressure Sensor, Display and Switch

- 10 bar g steam pressure transmitter, indicator and PNP switch - Steam pressure transmitter with LED display indicator for measuring 0 to 10 bars with in-built temperature reducer

- Truck loading monitoring using air cushion pressure - Pressure sensor and remote LED display for installing on a truck to monitor air cushion pressure during loading of a vehicle.

- 1 hPa Positive Room Pressure Sensor, Switch & Display - A 100 Pascal range positive room pressure sensor with a 0-10 volt analogue output signal relating to the inside/outside room pressure difference.

- Hastelloy diaphragm -100 to 50 kPa g range manometer - Small manometer device with membrane protected against corrosive material (chemicals) and which we would prefer to be covered with Hastelloy steel.

- Hot oil pressure transmitter & display to read up to 5 bar at 300degC max - Pressure transmitter with an integral LED loop powered digital display for use with hot oil up to 300 deg. C (max.) over a pressure range of 0-5 bar gauge.

- 10 metre high cylindrical oil tank level gauge and transmitter - Sensor and display for converting a pressure reading to a level reading of a 10 metre high cylindrical oil tank.

DS200 Combined Pressure Switch, Gauge and Sensor

DS200 Combined Pressure Switch, Gauge and Sensor DS201P High Range Flush Pressure Gauge, Switch and Sensor

DS201P High Range Flush Pressure Gauge, Switch and Sensor

- Autoclave pressure sensor and display with 10 bar range - We are looking for a autoclave pressure sensor and display for connecting to a laboratory steam sterilising autoclave and operates at about 10 bar @160°C

- 0 to 9 pascals range pressure gauge - Low Pascal range pressure gauge for measuring from 0 to 9 pascals and provide a digital readout of the pressure readings?

- Negative 30 inHg vacuum gauge with 0-10V output - Dual-function vacuum gauge with digital display and 0-10V output for industrial process control and monitoring.

- Low pressure methane gas transmitter with display and switch - I am looking for a 4-20mA pressure transmitter device for measuring the pressure of methane (CH4) gas up to 160 mbar gauge.

Pressure Indicator Transmitters - Pressure indicator transmitters have a digital indicator for providing a local pressure reading, and a 4-20mA pressure transmitter.

Pressure Indicator Transmitters - Pressure indicator transmitters have a digital indicator for providing a local pressure reading, and a 4-20mA pressure transmitter. Pressure Indicator Transducers - Pressure indicator transducers with voltage output and integrated digital display. Ideal for applications requiring both local indication and remote monitoring. No batteries needed.

Pressure Indicator Transducers - Pressure indicator transducers with voltage output and integrated digital display. Ideal for applications requiring both local indication and remote monitoring. No batteries needed.

Find out more about Analog Output Pressure Gauges to determine which product options and capabilities will best meet your application requirements.

Analog output pressure gauges offer additional functionality over traditional mechanical gauges by integrating the immediate, on-site visual confirmation of a local display with the capability to transmit pressure readings to remote systems. This dual functionality is crucial in modern industrial environments where both local operational checks and centralized data acquisition or control are necessary. The inclusion of an analog output signal, such as the industry-standard 4 to 20mA current loop or a 0 to 10Vdc voltage signal, allows these gauges to seamlessly interface with Programmable Logic Controllers (PLCs), Distributed Control Systems (DCS), SCADA systems, or dedicated data loggers and process control instrumentation.

The choice between a 4 to 20mA and a 0 to 10Vdc output often depends on the specific application requirements and existing infrastructure. The 4 to 20mA current loop is particularly favored in many industrial settings due to its inherent noise immunity over long transmission distances and its ability to detect faults like a broken wire (as the signal drops to 0mA, below the 4mA live zero). Furthermore, many 4-20mA devices can be loop-powered, simplifying wiring by drawing operating power from the signal loop itself. Conversely, 0 to 10Vdc voltage outputs are often simpler to interface with certain types of data acquisition cards or control systems that are more readily configured for voltage inputs, particularly in laboratory or test bench environments where electrical noise might be less of a concern or can be more easily managed.

These instruments typically feature a clear digital display, either LED (Light Emitting Diode) or LCD (Liquid Crystal Display), providing a precise and unambiguous local pressure reading. This digital readout offers superior accuracy and legibility compared to the parallax errors and interpolation often associated with traditional dial gauges, especially under challenging lighting conditions or when readings need to be taken quickly. The LED displays are generally brighter and easier to read from a distance or in low light, while LCDs are more power-efficient, which can be an advantage in battery-powered or power-constrained applications.

The utility of analog output pressure gauges spans a wide array of applications. In manufacturing plants, they can be installed on hydraulic power units, pneumatic systems, or coolant lines, allowing operators to verify pressures locally while the same data informs automated control sequences or quality monitoring systems. For process skids, such as those used in chemical dosing, water treatment, or fuel handling, these gauges provide essential local indicators for commissioning and maintenance, alongside the continuous data feed for the main control system. Research and development labs also benefit from their use on test rigs and experimental setups, where precise local pressure monitoring is coupled with data logging for analysis and validation. Engineering consultants often specify these types of gauges for system upgrades or new installations where integration with modern control architectures is a key requirement, ensuring both immediate operational insight and long-term data utility.