Vacuum range digital interface pressure sensors for connecting to computer serial bus or other intelligent interface.

Products

DCT531P RS485 Modbus RTU Flush Pressure Sensor - RS485 Modbus RTU serial interface pressure sensor with exposed all welded stainless steel 316L flush diaphragm in ranges from 100mb up to 40 bar gauge or absolute.

DCT531P RS485 Modbus RTU Flush Pressure Sensor - RS485 Modbus RTU serial interface pressure sensor with exposed all welded stainless steel 316L flush diaphragm in ranges from 100mb up to 40 bar gauge or absolute. 33X High Accuracy Digital Output Pressure Sensor - High precision pressure transducer with an accuracy of 0.05% full scale with a RS485, USB or RS232 digital interface for connecting to a PC.

33X High Accuracy Digital Output Pressure Sensor - High precision pressure transducer with an accuracy of 0.05% full scale with a RS485, USB or RS232 digital interface for connecting to a PC.

Applications

15 psi absolute range RS485 Modbus RTU protocol interface vacuum sensor for research use - A vacuum range absolute pressure sensor for research use to measure pressure of air over a range of 0 to 15 psi abs from the 1/4 NPT male process connection, and sending the corresponding RS485 Modbus RTU signal through the M12x1 plug electrical connection.

15 psi absolute range RS485 Modbus RTU protocol interface vacuum sensor for research use - A vacuum range absolute pressure sensor for research use to measure pressure of air over a range of 0 to 15 psi abs from the 1/4 NPT male process connection, and sending the corresponding RS485 Modbus RTU signal through the M12x1 plug electrical connection. -1 to 6 bar differential RS485 Modbus RTU freshwater pressure sensor for farming use on a 6bar line - A compound range differential pressure sensor for farming use to measure pressure of freshwater over a range of -1 to 6 bar diff on a 6 bar freshwater line from two G1/4 male process connections, and sending the corresponding RS485 Modbus RTU signal through the M12 connector electrical connection.

-1 to 6 bar differential RS485 Modbus RTU freshwater pressure sensor for farming use on a 6bar line - A compound range differential pressure sensor for farming use to measure pressure of freshwater over a range of -1 to 6 bar diff on a 6 bar freshwater line from two G1/4 male process connections, and sending the corresponding RS485 Modbus RTU signal through the M12 connector electrical connection.

30 inHg absolute RS232 output vacuum range pressure sensor

30 inHg absolute RS232 output vacuum range pressure sensor 1 bar vacuum gauge and sensor with USB plus Labview driver

1 bar vacuum gauge and sensor with USB plus Labview driver

Related Product and Application Guides

Checklist for digital vacuum pressure sensor requirements

Define your digital vacuum pressure sensor requirements using this checklist:

- Vacuum range?

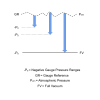

- Reference type?

- Digital interface type?

- Accuracy?

- Electrical connection?

- Media type?

- Process connection?