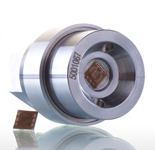

Silicon pressure sensors have silicon based sensing diaphragms which have a very high elasticity and semiconductor strain gauges implanted in the silicon substrate which produce a high span sensitivity.

Silicon pressure transducers have a high mV/V output signal, high overpressure and very good non-linearity, hysteresis and repeatability measurement precision.

Pressure transducers & transmitters with silicon strain gauge sensing diaphragms which have output signals with good linearity, hysteresis and short term repeatability. Semiconductor pressure sensors also have high overpressure ratings and sensitivity due to the high gauge factors of the semiconductor strain gauges.

Choose a silicon pressure sensor from the list below to view product specification details and request a price quotation.

Air classification system powder duct pressure transmitter with +/-15 kPa range and ATEX/IECEx IS cert - This pressure transmitter with open port design is ideal for monitoring duct pressures in powder air classification systems. It features ATEX/IECEx IS certification and a -15 to +15 kPa range.

Air classification system powder duct pressure transmitter with +/-15 kPa range and ATEX/IECEx IS cert - This pressure transmitter with open port design is ideal for monitoring duct pressures in powder air classification systems. It features ATEX/IECEx IS certification and a -15 to +15 kPa range. SIL2 approved 10 bar pressure transducer with 4 to 20 mA output - Pressure transducer with SIL 2 approved electronics that provide a 4-20mA output over a 0-10bar working range.

SIL2 approved 10 bar pressure transducer with 4 to 20 mA output - Pressure transducer with SIL 2 approved electronics that provide a 4-20mA output over a 0-10bar working range.

DS200P Sanitary Low Range Pressure Gauge, Switch and Sensor

DS200P Sanitary Low Range Pressure Gauge, Switch and Sensor IMPLR Low Range All Stainless Steel OEM Pressure Sensor

IMPLR Low Range All Stainless Steel OEM Pressure Sensor DMP331 Precision Pressure Transmitter

DMP331 Precision Pressure Transmitter UPS-HSR USB Pressure Sensor with High Sample Rate Logging

UPS-HSR USB Pressure Sensor with High Sample Rate Logging

- Ex rated ambient pressure sensor with 800-1100 mbar range - Could you give details of a high accuracy pressure sensor which measures ambient pressure (800 to 1100 mb) for environmental purposes.

- 20 bar absolute steam pressure transducer - Pressure transducer for measuring a closed steam system pressurized by Nitrogen up to pressures of 20 bar

- 180 degC pressure sensor for saturated steam up to 10 bar - A built-in cooling element allows the pressure sensor to be used on media temperatures up to 200 degC (FKM seal limit).

- 1013 to 1400 mbar barometric pressure transmitter & readout - barometric pressure transmitter that can measure ambient air pressure from 1013-1400 mb in a chamber and provide a 4-20 mA output signal.

- 180°C UHT milk compatible pressure transmitter - Pressure transmitter for high temperature UHT milk up to 180°C with 6 bar pressure range and ½ inch fitting process connection

- Anaerobic digestion methane gas 2bar pressure transmitter - ATEX pressure transmitter to measure the pressure of methane gas line in an anaerobic digestion plant.

33X High Accuracy Digital Output Pressure Sensor

33X High Accuracy Digital Output Pressure Sensor DMP343 Low Range Pneumatic Pressure Sensor

DMP343 Low Range Pneumatic Pressure Sensor DS210 Combined Low Pressure Switch, Indicator and Sensor

DS210 Combined Low Pressure Switch, Indicator and Sensor DMP333 High Range Precision Pressure Transmitter

DMP333 High Range Precision Pressure Transmitter

- Waterproof testing to 2 atmospheres digital pressure sensor - PR 33X is a high resolution digital interface pressure sensor that can be hooked up to a Windows PC to display and log the pressure. The 33X uses a high resolution 16 bit analog to digital converter to process the signal generated by the pressure transducer, and therefore it is possible to detect very small variations in pressure.

- Saturated steam pressure transmitter for 185psi max pressure & 392F max temp - The DMP331P can be used on saturated steam up to 392F (200C) if the integrated cooling element option is included

- Gas sensors testing barometric pressure sensor with RS485 Modbus RTU interface - We are looking to make high accuracy barometric measurements to use in the testing of gas sensors in an indoor laboratory environment at room temperature.

- USB pressure sensors for detecting water leaks & restrictions - I have a research problem where I need to detect leaks and obstructions in a pipe network

- 1000 psi USB connection pressure transducer for PC data acquisition - Pressure transducer with USB connection and PC software for data acquisition of pressures from 0 to 1000 psi gauge.

- Stainless steel 316L wetted parts 100 mbar ATEX pressure transmitter - ATEX and IECEX certified pressure transmitter for gas or dust and has all stainless steel 316L for use with liquids, and a low pressure range capability.

- Atmospheric air pressure transducer with 10 volt output

- 5 to 20 psi absolute ambient 4 to 20 ma pressure transmitter

- Dust ATEX approved 2 psi pressure transmitter

- Barometric 550 to 1150 hPa abs high resolution pressure transmitter

- Powder filter blockage monitoring pressure transmitter

- Air flow normalising calculation barometric pressure transmitter

- Leak testing at 0.5 bar to detect 200 Pascal pressure drop

- Solar-powered pressure sensing for remote wastewater networks

- Remote monitoring of natural gas pressure in large commercial buildings

- Low power fast response differential pressure sensing for IoT water network logging

- Marine engine crankcase pressure and splash oil temperature with a dual output transmitter

- Near-atmospheric pressure transmitter for hazardous gas test chambers

Find out more about Silicon Pressure Sensors to determine which product options and capabilities will best meet your application requirements.

Advantages of Silicon Pressure Sensors

Pressure sensors that utilise silicon sensing elements offer many advantages over other pressure sensing technologies, they are small, lightweight, highly repeatable, stable over time, dynamically responsive and very sensitive to variations in pressure.

100% Elastic

The base diaphragm material is typically ‘n’ type mono-crystalline layer Silicon which is 100 % elastic to its breaking point and therefore is a perfect material for use as a sensing diaphragm.

Repeatability

The strain gauges which are the key elements for converting pressure into an electrical signal are created by ion implantation of masked areas of the silicon in to create tiny ‘p’ type regions at strategic points on the diaphragm surface. When a reverse bias voltage is applied between the ‘n’ type substrate and ‘p’ type regions the ‘p’ type regions become electrical isolated and due to the relative increased conductivity of the ‘p’ type region they exhibit resistive characteristics and when pressure is applied the ‘p’ type regions behave as strain gauges. Since the strain gauges are chemically changed areas of a uniform piece of material they will deform almost perfectly with the stresses of the diaphragm without lag or separation and thus the repeatability of measured pressure points is very good over many pressure cycles.

Low Hysteresis

The combination of a high elasticity material and near perfectly bonded and integrated strain gauges produces a structure with very little hysteresis ensuring that pressure readings are precise regardless of the direction of changing pressure.

High Gauge Factors

The p type region or semiconductor strain gauge is behaves in a similar way to more conventional foil strain gauges with a change in resistance when the gauges are stretched or squeezed, however there is an added semiconductor property which combines with the resistive variation to increase the sensitivity or gauge factor of the Silicon strain gauge. Thus high levels of voltage drop can be achieved across semiconductor strain gauges for a given pressure change which allows users to make better use of analogue to digital resolution and improve signal to noise ratios.

Small Size and Lightweight

Silicon piezo-resistive elements are manufactured in the same way that miniature silicon chips are that are used in micro-electronics. The combination of chemical etching micro-machining, doping and masking techniques to create mechanical structures with micro-electronic components enables the productions of very small sensing elements. This in turn helps engineers to design smaller pressure sensors since the sensing diaphragm for other technologies is often the limiting factor controlling the diameter of the final design.

Low Susceptibility to Acceleration

The small size and low weight of silicon sensing elements make them less susceptible to acceleration. Therefore these sensors are often used in applications which have high levels of ‘G’, shock or vibration.

Long Term Stability

Semiconductor strain gauges are not glued, printed or electro-plated to the surface to the sensing diaphragm. And instead are a chemically changed part of the same material. Over time strain gauge bonds can deteriorate or change with pressure and temperature cycling causing instabilities in the sensor performance. Semiconductor strain gauges have no bonds and therefore are extremely stable in comparison.

High Overpressure Rating

The higher gauge factors of semiconductor strain gauges compared to other types of strain gauge make it possible to use stiffer diaphragms for a given pressure range to allow a high overpressure rating to be specified without compromising too much sensitivity. The high elasticity of Silicon also makes it possible to strain Silicon further than other less elastic diaphragm materials with virtually no resulting stress.

Dynamic Response

Due to high sensitivity of semiconductor strain gauges the thickness to cross-sectional area is relatively high for a sensing diaphragm plus the miniature size results in a very high natural frequency in the order of 10 – 100 kHz. This combined with the elasticity and atomically bonded strain gauges makes Silicon strain gauge diaphragms highly responsive to rapid changes in pressure.

Disadvantages of Silicon Pressure Sensors

Some of the potential issues that should be discussed with manufacturers before selecting silicon pressure sensors in the following applications.

Shock pressures

Hydraulic pressure systems can generate very rapid changes in pressure, due to high speed actuation and valve operation, plus the rapid responsiveness of the hydraulic system architecture.

Systems with water flowing in pipe work are prone to water hammer. When a valve is closed quickly it will cause a sudden drop in flow speed, which translates as shock pressure, and produces a knocking noise, hence the name water hammer.

These shock pressures can easily exceed the pressure rating of silicon pressure sensors damaging the silicon diaphragm or rupturing the very thin metal isolation diaphragm of oil filled silicon sensor capsules.

High vacuum

Many types of silicon pressure sensors have the silicon chip element incorporated inside an oil filled metal capsule with a thin isolation diaphragm to allow the oil fill to be pressurised and measured by the silicon chip. When a vacuum is applied to the isolation diaphragm, it will subsequently generate a vacuum in the oil fill.

The oil used should have a very low saturated or equilibrium vapour pressure, and has to be heated separately along with the empty metal capsule, prior to the filling process, in a high vacuum to remove water and other liquids with a high vapour pressure. The amount of attention that is given to this stage of the manufacturing process will affect how well the silicon pressure sensor performs over the vacuum range, particularly at high vacuum.

Even though a measurement at high vacuum is unlikely to be useful, due to the accuracy limitations of silicon pressure sensors in measuring high vacuum, there maybe consequences which typically show as a calibration shift, either temporarily or more permanently.

Chemical corrosion

As mentioned above the silicon part of silicon pressure sensors, refers to the silicon chip transducer technology which is the fundamental electromechanical component which is measuring the pressure.

Due to the complex construction and vulnerability to direct contact with, and exposure to the process media in many applications, it is often necessary to package the silicon chip assembly inside a hermetically sealed metal capsule to protect it from damage.

Stainless steel is the most common metal used in the construction of the capsule, including the isolation diaphragm, although this can be made from other more exotic metals such as hastelloy, monel, inconel and titanium for more demanding applications. However some chemicals are highly corrosive to metals, particularly the very thin isolation diaphragms, and in these cases other sensor technologies such a ceramic pressure sensors have to be used instead.

Low pressure

Due to the small silicon chip size, it becomes impractical and uneconomical to produce sensing elements which provide sufficient performance at very low pressure ranges.

Exposed silicon sensors without oil filled capsules, have more measurement sensitivity and thus better accuracy performance at lower ranges, but they are still limited to range of a few millibars or inches of water.

High pressure

The fabricated construction of the majority of silicon pressure sensing elements, makes it much more difficult to produce a robust and long lasting product design for use in very high pressure applications. Very high pressure sensors are typically made from an all stainless steel sensing element with as few welds as possible.

Silicon strain gauges are sometimes incorporated into stainless steel sensing diaphragms, but these are not strictly classed as silicon pressure sensors since the fundamental sensing element is made from stainless steel.

High temperature

Silicon sensing technologies which rely on different types of semiconductor regions have a maximum operating temperature which is fundamental limitation imposed by the physics of semiconductors. If this temperature limit is exceeded the electronic properties begin to breakdown and lead to a loss of sensor performance.

In order to use silicon pressure sensors at higher temperatures than is allowed by the particular silicon sensor technology, it is necessary to incorporate cooling features, to reduce the temperature around the silicon chip to operational limits.

Low temperature

Oil filled silicon pressure sensors will perform differently at low temperatures due to the thickening of the oil and at extreme low temperatures. This directly affects the performance of a silicon pressure sensor, which relies on a highly fluid coupling between the process media and silicon chip.

Hydrogen gas

As mentioned previously, many types of silicon pressure sensors have the silicon pressure sensing chip hermetically sealed within an oil filled capsule with a very thin metal diaphragm to transfer the pressure.

Hydrogen is the smallest sized element and exists in a gaseous state under standard ambient temperature and pressure conditions.

Due to Hydrogen relative small size and mobility as a gas, some hydrogen ions will pass through thin materials, and over time a significant quantity will migrate from one zone to another, especially if there is pressure difference between the two zones.

Hydrogen ions can diffuse through the very thin isolation diaphragm of some silicon pressure sensors, which will affect the calibration of the sensor, and may lead to other issues depending on the material and methods used to construct the sensor. This permeation can be combated by coating the isolation diaphragm with a material which blocks the passing through of hydrogen gas such as plating it with gold or other material which is much denser than the base isolation diaphragm material.

Some steels are susceptible to Hydrogen embrittlement where hydrogen accumulates within the steel over time eventually causing minor cracks to form which eventually cause the steel to fail. It is possible to prevent this from occurring by adopting the use of high grade stainless steels such as 316 in the manufacture of the components exposed to hydrogen gas.

FAQ

Questions and Answers about silicon peizoresistive pressure sensor technology for both the exposed and oil filled capsule mounting arrangements for the sensor used in silicon pressure sensors.

Sensing Diaphragm Material & Performance

How well does the sensing diaphragm material perform for elasticity, hysteresis, repeatability and robustness?

Exposed/Isolated – The sensing diaphragm is constructed from silicon, offering exceptional performance due to its near-perfect elasticity, minimal hysteresis, high repeatability, and overall robustness. This ensures accurate, reliable, and consistent pressure measurements even under demanding conditions.

Media Compatibility

How protected is the pressure sensor module assembly against different types of aggressive media, and how customisable is the construction to enhance protection to a particular media type?

Exposed – Silicon, adhesive, and silicone are used to mount the silicon chip in a sensor assembly, and in some cases the electrical contacts will be exposed to the media, leaving the sensor extremely vulnerable to corrosion damage.

Isolated – The isolated version of this technology has a metal isolation diaphragm, which is very thin, making it vulnerable to pitting, and although it has low corrosion rates depending on metal type, they can become significant over the service life compared to thicker metal components. however since it is easier to modify the isolation diaphragm and module material that contains the silicon chip sensor, it is possible to offer alternative wetted materials for better media compatibility.

Oil Leakage

Is there a risk of oil leakage from this sensor, which could impact performance or safety?

Exposed – No oil is used in the construction of this type of silicon based pressure sensor, in this design the silicon is exposed directly to the process media, in order to minimise the size of the package, provide a good signal and overall accuracy at lower pressures.

Isolated – Yes this design uses an oil fill. Various types of oil can be used, but all add complexity to manufacturing, and there are risks of calibration shift due to formation of gas pockets within the oil-fill if certain precautions such as filling under high vacuum are not carried out during manufacture. Rapid pressure changes can cause dynamic movement of oil leading to internal damage of electrical contacts and isolation diaphragm. Some oil types are prohibited in some applications, due to a contamination hazard if the thin isolation diaphragm is compromised and leaks oil into the liquid or gas being measured.

Pressure Containment

How well are the internal components joined together to provide a seal to withstand pressurisation that exceeds normal operating conditions, without degradation due to pressure and temperature cycling over the lifetime of the sensing device?

Exposed – Various bonds between adhesive, elastomer seals, and glass lead to an assembly which is less protected from leaks and damage caused by corrosion, pressure surges and temperature cycling.

Isolated – There a two ways of mounting the silicon sensor capsule inside a pressure sensor, one is to weld it which provides a reliable pressure seal , and the other is to use elastomer seals instead which are lower cost and quicker to manufacture, however they are more likely to degrade over time if exposed to less-compatible chemicals or extremes of temperature.

Small Size

How small a pressure sensor is it possible to make with this sensing technology?

Exposed – Silicon chips can be incredibly small in size and therefore it is possible to incorporate them into miniature sized packages for applications in research where they are looking minimal impact to weight and size on their experiments, or motorsport where they are always trying to save more on size and weight of the components used on the vehicles.

Isolated – Since the silicon chip is a very small sensing device, and because it is made using micromachining techniques, it is possible to shrink down the isolation capsule that it is mounted inside, and still achieve a smaller package than is achievable with most other types of pressure sensor technology.

Corrosion Resistance

How resistant are the media exposed materials to corrosive substances?

Exposed – Although the silicon substrate has good corrosive resistance to most substances, the materials such as industrial adhesives, sealing compounds and coatings are not as resistant, and are vulnerable to being attacked by corrosive chemicals.

Isolated – Compatible with most common fluid and gases, altough the thin isolation diaphragm is vulnerable to pitting, but a wide choice of isolation diaphragm material types make it possible to achieve compatibility if it is a known single corrosive substance.

Abrasion Resistance

How resistant are the media exposed materials to abrasive substances?

Exposed – Not very resistant due to exposed adhesives, coatings and in some cases electrical contacts, which would be easily damaged by abrasive media.

Isolated – Easily damaged due to vulnerability of thin metal isolation diaphragm, which can be quickly worn away by if exposed to the path of fast moving abrasive fluids or gases containing particles.

High Pressure Spikes

What are the chances of a noticeable effect on the sensors operational performance, or damage to the sensors internal components, from exposure to very dynamic or quickly changing pressures, such as hydraulic pressure spikes or water hammer?

Exposed – The sensor constuction is not suitable for high pressure operation, since it is not a fully welded construction, but instead a fabricated construction of different materials each of varying strength, plus there is risk of inconsistency during manufacturing steps of applying industial adhesives, and coatings, which would lead to a more unpredictable resilience against rapid changing high pressure events.

Isolated – An all welded metal construction makes this sensor type more predictable and robust against sudden high pressure rise and fall, but the thin isolation diaphragm and oil filling, makes its vulnerable to cavitation damage where the diaphragm can be ripped apart or the oil filling shunted around inside the capsule, causing internal damage to the connections to the silicon chip.

Overpressure Handling

How affected is the accuracy performance of the sensor by an overpressure condition, where the pressure exceeds 100% of range?

Exposed – The silicon chip has a very high overpressure rating due to its 100% elasticity and high output senstivity, but this is countered by the materials that are used to mount and bond the silicon, which may change after excessive stress from overpressure, causing a shift in calibrated accuracy.

Isolated – It is possible to achieve high overpressure ratings for oil filled silicon capsule, since silicon maintains its elasticity to breaking point and the strain gauges produce high gauge factors allowing the pressure range to be reduced compared to other technologies and thus increasing the overpressure rating as a result. Also since the force is transferred through the oil to the sensor it is possible to mount the silicon chip using advanced techniques to decouple it from the mechanical changes of surrounding assembly materials which would otherwise affect the accuracy performance following an overpressure condition.

Very Low Pressure Ranges (<100 mbar)

How well does it perform measuring very low pressures with a pressure range lower than 100 mbar?

Silicon’s single crystalline structure and the precision afforded by micromachining etching techniques enable the creation of exceptionally high-performing silicon chips tailored for very low-pressure measurements. These chips boast remarkable repeatability and relatively high gauge factors, owing to their meticulously optimized mechanical structures at the microscopic level. This inherent sensitivity, combined with the low hysteresis and excellent stability of silicon strain gauges, positions this technology as one of the best choices for applications demanding precise and reliable low-pressure sensing.

Exposed – Due to the high output sensitivity and direct contact with the media, this makes it possible to work very well for pressure ranges as low as 1 mbar.

Isolated – The oil-filled capsule design, while offering certain advantages, negatively impacts performance at very low pressures. The additional diaphragm and oil introduce factors like reduced output sensitivity, temperature-dependent changes in oil properties, and increased hysteresis, all of which can affect measurement accuracy in this range.

Low Pressure Ranges (100-1000 mbar)

How well does it perform measuring low pressures with a pressure range between 100 and 1000 mbar?

The single-crystalline structure of silicon, combined with the precision of micromachining etching techniques, enables the creation of highly optimized micromechanical structures on silicon chips. This translates to exceptional performance in the low-pressure range of 100 to 1000 mbar. These silicon chip strain gauges exhibit good repeatability and relatively high gauge factors, making them well-suited for accurate and reliable pressure measurements in this regime. The inherent material properties of silicon, coupled with advanced microfabrication techniques, contribute to the superior performance of this technology in low-pressure applications.

Exposed – High output sensitivity and direct contact with media, provides good performance at lower pressure ranges.

Isolated – High gauge factors provide good signal to noise levels, and effects on performance due to oil filled isolation diaphragm become less noticeable.

Medium Pressure Ranges (1-100 bar)

How well does it perform measuring medium pressures with a pressure range between 1 and 100 bar?

Exposed – Although perfectly adequate to design a fabricated silicon chip assembly to operate in these pressure ranges, the weaker and less elastic elements such as the bonding materials and coatings are under more stress, and there is increased risk of performance changes as it ages.

Isolated – The silicon chip is protected by an oil filling, and the metal capsule is more than adequate to handle the stresses imposed on it over the medium pressure ranges, and due to being in a relative benign environment, it performs at its best over these ranges.

High Pressure Ranges (100-1000 bar)

How well does it perform measuring high pressures with a pressure range between 100 and 1000 bar?

Exposed – Difficult to provide pressure integrity for a fabricated diaphragm assembly to withstand, the stresses that would need to be endured at these levels of high pressure.

Isolated – The all welded outer metal construction of the capsule protects the silicon chip very well, and provides an adequate pressure containment rating, but it can be vulnerable to damage if the pressures are very dynamic which can cause the oil to shift around inside sharply and damage internal electrical connections and in extreme cases rupture the isolation diaphragm.

Very High Pressure Ranges (>1000 bar)

How well does it perform measuring very high pressures with a pressure range greater than 1000 bar?

Exposed – As with the high pressure band, it is difficult to provide pressure integrity for a fabricated diaphragm assembly to withstand, the stresses that would need to be endured at these levels of high pressure.

Isolated – At these very high pressures there is increased risk of damage due to the thin isolation diaphragms vulnerability to pressure surges & spikes, rapid movement of the oil filling causing internal components and connections to break.

Absolute Pressure Ranges

Can this sensor technology be easily adapted to measure absolute pressures, or pressures referenced to a hard vacuum?

Exposed – Unlike the gauge reference method of construction which typically has the electrical contacts to the silicon on the same side as the ambient pressure reference, for measuring absolute pressures, it is necessary to invert the silicon chip so that internal wire connections to the silicon chip are facing the measurement side instead. This is because the reference side is used for trapping a vacuum to use as an absolute reference, and passing wire connections through a vacuum seal would add more complexity to the sensor design. Therefore absolute versions are limited to measuring dry non-condensing gases, or having a layer of gel covering the silicon chip on the measurement side to protect the connections from moisture damage, which in turn has an adverse effect on the accuracy performance of the sensor.

Isolated – This design type is perfect for measuring absolute ranges because the electrical contacts to the silicon chip are protected by a dielectric oil filled capsule. Any media which is compatible with the outer metal construction of the capsule can be measured without damaging the sensor.

Accuracy

What level of accuracy performance is achievable from the combined effects of linearity, hysteresis, short term repeatability, temperature errors, and long term stability?

Exposed – The 100% elasticity of silicon, perfectly implanted strain gauges with very similar mechanical properties to the surrounding silicon substrate, provide excellent linearity, very small hysteresis and repeatibility errors over the operating pressure range. The temperature errors can be quite large if not adequately compensated, but they are very repeatable, and can be reduced considerably with digital compensation techniques.

Isolated – Same as above but the addition of the oil filling and isolation diaphragm introduces some drop in performance partly due to thermal expansion of the oil adding to the thermal errors, and damping of the sensing response leading to increased hysteresis, and short-term repeatability errors.

Output Sensitivity

What is the level and quality of the output produced from the transducer technology, before any signal conditioning electronics is added?

Exposed/Isolated – The semiconductor strain gauges, which are created by implating ions into masked regions of the silicon substrate, have very high gauge factors due to the piezoresistive properties of semiconductor strain gauges, in addition to the geometric resistance effect when a strain gauge changes shape under stress. This means that silicon strain gauges have a far greater sensitivity to pressure changes than other pressure sensing technologies which produce a much smaller piezoresistive effect, and rely more on the geometric resistance effect.

Frequency Response

How quickly does the sensor’s output respond to changes in pressure?

Exposed – Due to very low mass, very small size, sensing diaphragm rigidness, and implanted strain gauges of silicon strain gauge chips, they have very high natural frequencies, and are able to react extremely quickly to changes in pressure.

Isolated – Same qualities as exposed silicon diaphragm above, but the frequency response will be slightly reduced by damping due to the added oil fill and metal isolation diaphragm surrounding the silicon chip.

Compare with other pressure sensor technologies

How do pressure sensors that use a silicon diaphragm with diffused piezoresistive strain gauges compare to other technologies?

| Sensing technology | Si-Chip | Si-Isolated | Thick-Film | Var-Cap | Thin-Film | BFSG |

|---|---|---|---|---|---|---|

| Sensing diaphragm material | Excellent | Excellent | Fair | Fair | Good | Good |

| Media compatibility | Bad | Good | Excellent | Excellent | Good | Good |

| Oil fill leak risk | Excellent | Bad | Excellent | Excellent | Excellent | Excellent |

| Pressure containment | Poor | Good | Fair | Fair | Excellent | Excellent |

| Small size | Excellent | Good | Fair | Poor | Good | Fair |

| Corrosion resistance | Bad | Good | Excellent | Excellent | Fair | Fair |

| Abrasion resistance | Bad | Bad | Excellent | Excellent | Fair | Fair |

| High pressure spikes | Bad | Poor | Fair | Poor | Good | Good |

| Overpressure rating | Good | Excellent | Fair | Good | Poor | Poor |

| Very low pressure < 100mb | Good | Poor | Bad | Good | Bad | Bad |

| Low pressure 100…1000mb | Good | Good | Poor | Good | Bad | Bad |

| Medium pressure 1…100bar | Fair | Excellent | Excellent | Fair | Good | Fair |

| High pressure 100…1000bar | Bad | Good | Fair | Bad | Excellent | Good |

| Very high pressure > 1000bar | Bad | Bad | Bad | Bad | Good | Excellent |

| Absolute pressure ranges | Fair | Excellent | Good | Good | Bad | Bad |

| Accuracy | Excellent | Good | Poor | Fair | Good | Fair |

| Output Sensitivity | Excellent | Excellent | Fair | Excellent | Good | Fair |

| Frequency response | Excellent | Good | Fair | Poor | Good | Fair |

| Comparison rating (90 max) | 56 | 63 | 59 | 61 | 62 | 57 |

Which technology to use for your application?

Find out whether silicon pressure sensors will be the most suitable choice for your application compared to other technologies.

Product Help

Understanding temperature compensation

What does the ‘temperature compensation’ specification for a silicon pressure sensor actually refer to? Is it correcting for the ambient temperature around the sensor’s housing or for the temperature of the process media in contact with the sensing diaphragm?

Temperature compensation in a pressure sensor primarily addresses the thermal effects on the internal sensing components, which are in very close proximity to the process media. Therefore, the media temperature is the most critical factor.

The components most sensitive to temperature changes are the strain gauges embedded in the silicon chip, typically housed within an oil-filled capsule sealed by an isolation diaphragm. These strain gauges are designed to be highly sensitive to the physical deflection caused by pressure. However, they are also sensitive to thermal expansion and contraction, which can introduce significant measurement errors if not corrected. The expansion and contraction of the internal oil fill also contribute to thermal errors.

Compensation techniques are employed to counteract these effects.

- Digital Compensation: Modern sensors often use digital compensation. The sensor’s internal bridge resistance is used to measure the temperature at the silicon chip. A microprocessor then applies a correction algorithm based on characterisation data stored in its memory. This method is very precise within its specified temperature range (e.g., 10 to 40°C) but can lead to a rapid deterioration in accuracy if the temperature moves outside this range.

- Analogue Compensation: Older or simpler designs use analogue compensation circuits. While typically less accurate than digital methods, they are often more forgiving if the compensated temperature range is exceeded, with accuracy degrading more gradually.

While the sensor’s signal processing electronics are further away from the process media, they are generally built with components that have very low thermal coefficients and are much less affected by temperature changes. Therefore, when a datasheet mentions ‘environmental temperature’, particularly for process instrumentation, it is the temperature influencing the core sensing element that matters most.

Checklist for silicon pressure sensor requirements

Define your silicon pressure sensor requirements using this checklist:

- Pressure range?

- Overpressure?

- Output signal?

- Dynamic response?

- Accuracy?

- Electrical connection?

- Process connection?

- Size dimensions?

- Process media type?

- Media temperature range?

- Environment temperature range?

- Environment shock and vibration?

- Shock pressures?

- High vacuum exposure?

- Hydrogen exposure?