High temperature pressure transmitters with a 4-20mA output, tolerant to high temperature applications such as steam, food processing & engine monitoring.

High temperature pressure transmitters are engineered for direct and accurate pressure measurement in applications where media temperatures significantly exceed the limits of standard devices. These specialized instruments, typically providing a resilient 4-20mA output, are indispensable in scenarios such as steam systems, demanding food processing stages, and critical engine monitoring, particularly where the installation of standoff pipes or pigtail siphons for cooling is not feasible or desirable. Their robust design ensures reliable performance and signal integrity even when directly exposed to challenging thermal conditions, simplifying installation and enhancing process control.

16 bar, 200°C steam pressure transmitter and gauge - Combined pressure transmitter and indicator in one package with the option for use with high temperature media such as steam at 200°C

16 bar, 200°C steam pressure transmitter and gauge - Combined pressure transmitter and indicator in one package with the option for use with high temperature media such as steam at 200°C 180°C UHT milk compatible pressure transmitter - Pressure transmitter for high temperature UHT milk up to 180°C with 6 bar pressure range and ½ inch fitting process connection

180°C UHT milk compatible pressure transmitter - Pressure transmitter for high temperature UHT milk up to 180°C with 6 bar pressure range and ½ inch fitting process connection

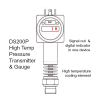

DS200P Sanitary Low Range Pressure Gauge, Switch and Sensor

DS200P Sanitary Low Range Pressure Gauge, Switch and Sensor IMPLR Low Range All Stainless Steel OEM Pressure Sensor

IMPLR Low Range All Stainless Steel OEM Pressure Sensor DMP331P Hygienic Flush Pressure Transmitter

DMP331P Hygienic Flush Pressure Transmitter 35X HTT High Temperature Compensated Pressure Sensor

35X HTT High Temperature Compensated Pressure Sensor

- Measuring steam pressure up to 10bar with analog/digital output - I am looking for an analog & digital type pressure sensor for use on steam temperatures from 0 to 200 degrees Celsius over 0 to 10 bar?

- 25 psi steam pressure measurement with a transmitter & display - 50 psi range 4-20mA output pressure transmitter for use on 25 psi saturated steam.

- Saturated steam pressure transmitter for 185psi max pressure & 392F max temp - The DMP331P can be used on saturated steam up to 392F (200C) if the integrated cooling element option is included

- 10 bar g steam pressure transmitter, indicator and PNP switch - Steam pressure transmitter with LED display indicator for measuring 0 to 10 bars with in-built temperature reducer

- All-In-One transmitter for measuring steam temperature to 150°C and pressure to 4kg/cm² g - All-in-one pressure and temperature transmitter for high temperature media such as steam up to 150 degrees Celsius for measuring pressure over 0 to 4 kg/cm2g and temperature over 0-150 degC.

- 300 F protected 100 psi pressure transmitter - The IMP is a low cost pressure transmitter which has the option for a built-in process connector extender designed to reduce the temperature.

ATM/T Pressure and Temperature Dual Output Transmitter

ATM/T Pressure and Temperature Dual Output Transmitter DMK331P Flush Diaphragm Pressure Sensor

DMK331P Flush Diaphragm Pressure Sensor DS201P High Range Flush Pressure Gauge, Switch and Sensor

DS201P High Range Flush Pressure Gauge, Switch and Sensor

- Hot oil pressure transmitter & display to read up to 5 bar at 300degC max - Pressure transmitter with an integral LED loop powered digital display for use with hot oil up to 300 deg. C (max.) over a pressure range of 0-5 bar gauge.

- 300°C max temperature, 0 to 300 bar, high range pressure sensor - The 35X HTC can measure up to 300 bar (and higher if necessary) on media up to temperatures of 300 degC max.

- Autoclave pressure sensor and display with 10 bar range - We are looking for a autoclave pressure sensor and display for connecting to a laboratory steam sterilising autoclave and operates at about 10 bar @160°C

- Aerospace component testing hi-temp air pressure sensor for up to 300C with 20 barg range - Conduct accurate aerospace component testing with the DMP 331P pressure sensor. With a 20 bar g range and 300°C temperature capability, it's ideal for testing pneumatic valves, heat exchangers, and sensors under simulated operating conditions.

- 20 barg 4-20mA output 200degC steam pressure sensor for process control use - A hi-temp media 200°C/392°F max gauge pressure sensor for process control use to measure pressure of steam over a range of 0 to 20 bar g from the 1/2 BSP flush diaphragm male process connection, and sending the corresponding 4-20mA signal through the M12 connector electrical connection.

- 10 bar g steam pressure transmitter - High temperature pressure transmitter for use with steam pressures up to 10 bar gauge.

Find out more about High Temperature Pressure Transmitters to determine which product options and capabilities will best meet your application requirements.

High temperature pressure transmitters featuring a robust 4-20mA output are specifically engineered for reliable operation in demanding thermal environments. These instruments are crucial in applications where the process media, such as superheated steam, certain food processing stages, or fluids within engine systems, consistently exceeds the operational temperature thresholds of standard pressure sensing devices. Their design circumvents the limitations of conventional transmitters, allowing for direct measurement even under extreme heat.

A key differentiator of these specialized transmitters is their intrinsic ability to withstand high temperatures without reliance on external cooling mechanisms. In many industrial settings, installing standoff pipes, pigtail siphons, or other cooling accessories to protect a pressure transmitter from excessive heat is either impractical due to space constraints, introduces potential points of failure or leakage, or can cause delays in pressure response. High temperature pressure transmitters eliminate these concerns by incorporating advanced sensor technologies and material selections that allow the sensing element to be directly or closely exposed to the hot media.

The 4-20mA analog output is a widely adopted standard in industrial automation and control systems, valued for its noise immunity over long transmission distances and its ability to power the device itself (in 2-wire loop-powered configurations). In high-temperature applications, maintaining signal integrity is paramount, and these transmitters ensure that the pressure readings are communicated reliably to control rooms or data logging systems, despite the challenging ambient conditions often found near hot processes.

Applications for high temperature pressure transmitters are diverse and critical. In steam systems, they are essential for monitoring and controlling pressure in steam lines, boilers, and autoclaves, where temperatures can rapidly fluctuate and reach extreme levels. For food processing, these transmitters play a vital role in pasteurization, sterilization (including Steam-in-Place or SIP cycles), and cooking processes where direct contact with hot food products or cleaning agents is common. Monitoring engine performance and safety also heavily relies on these devices, for instance, in measuring exhaust gas pressure, turbocharger conditions, or high-temperature oil and fuel pressures in automotive, marine, or power generation engines. The ability to operate without auxiliary cooling simplifies installation, reduces maintenance, and enhances the accuracy of pressure data in these thermally demanding scenarios.

Product Help

Specifying pressure transmitters for high temperature use

Process temperature

What will be the maximum process temperature reached in your application?

The sensor technology utilised in pressure transmitter has an operating temperature range which is adequate for most applications, but there are some which will require additional components to protect the sensor from heat damage.

Cooling mechanism

Typically the design approach is to reduce the temperature in the vicinity of the pressure transmitter by incorporating a mechanical cooling assembly to dissipate the heat.

The cooling assembly maybe filled with oil and separated from the process media by an isolation diaphragm.

Alternatively the cooling assembly can include hollow tubing shaped to increase heat transfer, which causes the process media allowed through, to reduce to a much lower temperature.

The choices of cooling mechanism fall into the following categories:

Add-on cooling adaptor

Add-on compact process media filled cooling adaptor with coiled capillary, hollow discs or fins for increasing surface area to act as heat sink for medium temperature protection.

Integral cooling element

Integral oil-filled isolation diaphragm seal shaped to increase surface area between sensor and isolation diaphragm to increase efficiency of cooling and provide for high temperature protection.

Capillary tube cooling

Integral oil, mercury or other fluid filled capillary with a long length and small diameter for extra cooling in very high temperature processes.

Ambient temperature

What will be the range of temperatures surrounding the pressure transmitter where it is installed?

This is an important consideration when dealing with high temperature processes or surrounding environments.

In applications where the process temperature is high, it is possible to use a pressure transmitter with a built-in cooling mechanism. This cooling mechanism often relies on the conduction and dissipation of heat to the surrounding air around the pressure transmitter. Therefore it is essential the ambient air temperature is lower than the process temperature. Also since the rest of the pressure transmitter connected to the cooling component is not protected from high temperatures, the ambient temperature should be lower than the device operating temperature range. This will ensure an efficient heat sink and protect the electronic components from thermal damage.

When it is not possible to install the pressure transmitter in a lower temperature environment, it is then necessary to use one that is completely protected from high ambient or process temperatures. These types of high temperature pressure transmitters do not need any cooling mechanism, and all components including the sensing technology, conditioning electronics, solder, adhesives, connectors and cables are rated to the maximum operating temperature.

Checklist for high temperature pressure transmitter requirements

Define your high temperature pressure transmitter requirements using this checklist:

- Process temperature?

- Cooling mechanism?

- Ambient temperature?

- Pressure range?

- Output signal? 4-20mA

- Electrical connection?

- Process connection?

- Process media type?