Sanitary pressure sensor with exposed diaphragm with no crevices for high temperatures up to 300 Degrees Celsius in ranges from 100mb up to 40 bar gauge or absolute.

The DMP 331P hygienic flush pressure transmitter has a selection of hygienic flush diaphragms for food & drink pressure or level measurement applications.

The DMP 331 P high temp hygienic pressure transmitter is ATEX/IECEx approved for intrinsic safety and with the sanitary flush diaphragm it is suitable for pharmaceutical & biotechnology applications.

Product Parameters

- Pressure Ranges: 0.1 bar to 40 bar gauge, 600 mb to 40 bar absolute

- Accuracy: 0.35% full scale > 0.4 bar (0.5% <= 0.4 bar), optional improved accuracy 0.25% FS, IEC60770

- Output Signals: 4-20mA current loop or 0-10V amplified voltage, optional ATEX/IECEx and SIL2

- Electrical Connections: DIN plug, IP67 cable gland, field housing or Binder connector

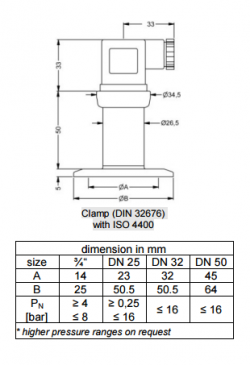

- Pressure Connections: Triclover clamp, dairy, Varivent and BSP screw-in threads

- Special Options: 300°C max. media temp (260 Deg C max with FFKM seal). with cooling element, food compatible oil fill, ATEX and IECEx approved for intrinsic safety, Hastelloy C276 or Tantalum wetted parts

Product Description

The DMP331P flush diaphragm pressure transmitter can be used on liquids or gases up to a maximum temperature of 300 Degrees Celsius.

High temperature media

The very high process media temperature tolerance is achieved by integrating a cooling element between the isolating flush membrane and the silicon strain gauge sensing element.

As long as the ambient temperature is significantly lower than the media temperature, the cooling element will dissipate high temperatures and reduce the temperature being conducted from the isolation diaphragm to a level that is within the operating temperature range of the pressure sensor electronics.

It is common practice to stand off a pressure sensor with a long piece of dead ended pipe to reduce the temperature at the sensor, but this can reduce the dynamic response of the pressure measurement and add unwanted volume to the system which can upset the performance of a test or a process.

By using a flush isolation diaphragm with a cooling element it is possible to measure high temp media pressures without introducing any extra volume to the system or damping the response of the pressure reading.

Hygienic fittings

A variety of hygienic flush diaphragms can be specified for clamp on or screw in fitment.

For sanitary food and biotech installations a food grade oil fill can be specified to protect the product being processed or stored in case the open diaphragm is accidentally damaged causing it to leak the fill fluid into the system.

Pressure ranges

The DMP331P high temperature pressure sensor can measure ranges from 100 millibar up to 40 bar with an accuracy of 0.175% full scale (0.25% for <0.4 bar) best straight line which includes non-linearity, hysteresis and repeatability errors.

Output signal

The pressure transmitter’s electronics provide a 4 to 20 milliamp current or 0-10 volt output signal. There is an ATEX approved version for intrinsic safety to allow use in a hazardous area with an appropriate IS zone barrier, and a SIL2 approved electronics version for applications requiring high electronic reliability.

Electrical connections

There are many electrical connections to choose from including an IP68 cable gland for external wash down cleaning of the sensor and the popular DIN43650A plug & socket with an IP65 protection rating.

Product Applications

Chocolate strainer condition monitoring

Measure chocolate pressure on a process line up to 100 psi to switch a chocolate pump when the strainer is full and clogged with nuts.

- SKU ID: s1-dmp331p-24-31666

- Pressure Range: 0 to 100

- Units: psi

- Range Type: Positive Gauge (atm to +P)

- Output Signal: 4-20mA (2 wire)

- Accuracy: 0.35% 0.4bar range min, 0.5% below

- Electrical Connection: DIN43650A plug IP65

- Process Connection: Clamp 1″ DN25 (DIN 32676), 3A

- Process Connector Material: Stainless steel 316L

- Diaphragm Material: Stainless Steel 316L

- Media & Temperature: 125degC max

CHP plant boiler steam header

Measure the pressure of CHP plant steam header at 220°C.

- SKU ID: s1-dmp331p-0009

- Part No: 500-1502-1-3-100-Z00-1-7-1-200

- Pressure Range: 15

- Units: bar

- Range Type: Positive Gauge (atm to +P)

- Output Signal: 4-20mA (2 wire)

- Accuracy: 0.35%

- Electrical Connection: DIN43650A plug IP65

- Process Connection: G1/2 Flush DIN3852, 1bar range min

- Process Connector Material: Stainless steel 316L

- Diaphragm Material: Stainless Steel 316L

- Media & Temperature: 260degC max, FFKM seal

Ice-cream level

Measure the level of ice-cream in a stainless steel vat.

- SKU ID: s1-dmp331p-0002

- Part No: 500-2000-3-5-850-M73-1-0-2-000

- Pressure Range: 0 to 2

- Units: mH2O

- Range Type: Positive Gauge (atm to +P)

- Output Signal: 0-10V (3 wire)

- Electrical Connection: Field housing IP67

- Process Connection: Dairy pipe DN25

- Process Connector Material: Stainless steel 316L

- Diaphragm Material: Stainless Steel 316L

- Media & Temperature: Food grade, 125degC max

Liquid Asphalt pressure

Measure the pressure in liquid Asphalt plumbing systems.

- SKU ID: s1-dmp331p-0008

- Pressure Range: 150

- Units: psi

- Range Type: Positive Gauge (atm to +P)

- Output Signal: 0-10V (3 wire)

- Accuracy: 0.35% 0.4bar range min, 0.5% below

- Electrical Connection: M12 x 1 connector (4 pin)

- Process Connection: G3/4 Flush DIN3852

- Process Connector Material: Stainless steel 316L

- Diaphragm Material: Stainless Steel 316L

- Media & Temperature: 200degC (Vac 150degC) max, FKM seal

Product Help

Maintaining room temperature acuracy at 180ºC

Is it possible to maintain the stated accuracy of 0.35% FS at +180C?

The accuracy stated below is for room temperature, there is also an additional error to consider when measuring over a dynamic range of temperatures, however if the high temperature temperature is stable it should be possible to achieve close to the room temperature performance by allowing for the changes in zero and span output settings at 180 degC.

The ambient temperature can also play a part in the accuracy since that will affect the temperature gradient along the cooling element, and therefore the temperature of the sensing element. If ambient temperature is fairly stable, then the accuracy of 0.35% should still be achievable at 180degC.

Voltage output response time

What is the response of the voltage output on this sensor?

The response time for the 3 wire 0-10Vdc output is < 3msec.

Accuracy over temperature

How accurate is this sensor over temperature?

The compensated temperature range is 0 to 50 degC for the sensing element and the tolerance over that range is < +/- 1.5% FS.

Highest allowed temperature

What is the highest temperature that this sensor can be used on?

In the standard configuration the maximum media temperature is 125°C/257°F and the maximum ambient environment temperature for the electronics is 85°C/185°F. The cooling element option will increase the maximum media temperature as follows:

- 150°C/302°F – Vacuum ranges and pressure ranges up to 1 bar absolute

- 200°C/392°F – Fitted with FKM seals

- 250°C/482°F – Food grade oil fill with FFKM seals

- 300°C/572°F – Silicone oil fill with FFKM seals

Silicon heat transfer fluid

Will this DMP 331P pressure transducer work at 250C with a silicon heat transfer fluid at and below pressures of 5 bar?

Yes you can use the DMP 331P on viscous media up to 260°C if supplied with the integrated cooler which dissipates the heat away before it reaches the electronic part of the sensor.

- SKU ID: s1-dmp331p-0007

- Part No: 500-5001-1-2-100-Z00-1-7-1-200

- Pressure Range: 5

- Units: bar

- Range Type: Positive Gauge (atm to +P)

- Output Signal: 4-20mA (2 wire)

- Accuracy: 0.35% 0.4bar range min, 0.5% below

- Electrical Connection: DIN43650A plug IP65

- Process Connection: G1/2 Flush DIN3852, 1bar range min

- Process Connector Material: Stainless steel 316L

- Diaphragm Material: Stainless Steel 316L

- Media & Temperature: 260degC (Vac 150degC) max, FFKM seal

Dairy chiller tank

We need to measure volume of contents of a chiller in a Dairy, a widely used technique is to measure hydrostatic pressure and convert the reading to a volume measurement. The pressure will be in the range of 100 mbar. As our commodity is classed as food grade, the sensor should be food grade rated and the measurement range should be in order of mbars.

We would suggest a DMP 331p with a food grade oil filled diaphragm seal, and a 1 inch clamp style process connection to meet the Dairy hygienic requirements, and a IP68 cable gland to protect the inside of the sensor when cleaning the outside of the chiller tank.

- SKU ID: s1-dmp331p-0006

- Part No: 500-1000-1-5-TR0-C61-0-2-000

- Pressure Range: 100

- Units: mbar

- Range Type: Positive Gauge (atm to +P)

- Output Signal: 4-20mA (2 wire)

- Accuracy: 0.35% 0.4bar range & above, 0.5% below

- Electrical Connection: IP68 (temp immersion) seal with 2m of cable

- Process Connection: Clamp 1″ DN25 (DIN 32676), 3A

- Process Connector Material: Stainless steel 316L

- Diaphragm Material: Stainless Steel 316L

- Media & Temperature: Food grade, 125degC max

Heated process oil tank level 50ft high

We need a liquid level sensor for installing externally to a tank to measure the quantity of heated process oil in a vertical storage tank 50 feet high.

The DMP311P with an integrated cooling element will allow you to measure the level of process oil up to temperatures of 200 degC if using an FKM seal on the process fitting.

- SKU ID: s1-dmp331p-0004

- Pressure Range: 0 to 50

- Units: ftH2O

- Range Type: Positive Gauge (atm to +P)

- Output Signal: 4-20mA (2 wire)

- Electrical Connection: IP67 seal with 2m of cable

- Process Connection: G1/2 Flush DIN3852, P>=1bar only

- Process Connector Material: Stainless steel 316L

- Diaphragm Material: Stainless Steel 316L

- Media & Temperature: 200degC, Vac < 150degC, FKM seal

Compensated & media temperature range

For the option where the media temperature is rated to 200°C, does this refer to the compensated temperature range?

There is a cooling element between the media and sensor so the compensated temperature range is much lower. 200°C refers to the media temperature upper limit. The cooling element works by dissipating heat into the surrounding ambient temperature air.

The compensated temperature range is -20 to +85°C, with the integrated cooling element, the pressure sensing element should not see higher than 85°C.

3/4″ Tri-Clamp & 121°C Autoclave

I would like a autoclave pressure sensor which would resistant to 121°C degrees for 30 minutes and working in a 0-3 bar range. The pressure sensor should have a 3/4″ TC connection.

As standard the DMP 331 P can be used on media temperatures up to 125 degrees Celsius, and a 3/4 inch TriClamp (TC) connection is also possible as specified below.

- SKU ID: s1-dmp331p-0003

- Part No: 500-3001-1-3-100-C69-1-0-1-000

- Pressure Range: 3

- Units: bar

- Range Type: Positive Gauge (atm to +P)

- Output Signal: 4-20mA (2 wire)

- Electrical Connection: DIN43650A plug IP65

- Process Connection: TriClamp 3/4″

- Process Connector Material: Stainless steel 316L

- Diaphragm Material: Stainless Steel 316L

- Media & Temperature: 125degC max

NPT threads with flush diaphragms

Do you offer any other threading options such as NPT for the DMP331P flush diaphragm pressure transmitter?

No the DMP331P is not available with a tapered NPT thread. Flush diaphragms and tapered threads such as the NPT type do not go together very well because the diaphragm is very sensitive to mechanical stresses during installation. An NPT thread seal is created by the tightening together of the male and female thread which causes a lot of localised stress. Parallel threads such as G1/4 do not provide the seal directly, but instead compress an O ring which sits around the outside of the male thread between two flat or grooved surfaces. A parallel thread requires significantly less torque than tapered threads to make a seal.

Also, it is often required by the installer to ensure that the flush diaphragm is not protruding from or recessing into the surface of the vessel wall. It is very easy to determine the precise depth of flush diaphragm when it is fitted with a parallel thread, but the depth a tapered thread device once installed is not so precise and can vary between devices and re-fitments of the same device.

-0.6 to +0.6 bar pressure range

Can the DMP331P pressure transmitter with flush pressure port be provided with a compound pressure range of -0.6barg to +0.6barg?

Yes it can, but it will be a custom scaling of the output and it should only be used with media that will always be below a temperature of +70 degrees Celsius.

180°C steam pressure

We are looking for units with ½” BSP connection for use on Steam at 180°C @ 12Bar with a range of between 0-20 BarG & an output of 4-20mA.

The DMP331P fitted with the cooling element and standard FKM seals will be suitable for temperatures up to 200°C.

- SKU ID: s1-dmp331p-0005

- Part No: 500-2002-1-3-100-Z00-1-1-1-200

- Pressure Range: 0 to 20

- Units: bar

- Range Type: Positive Gauge (atm to +P)

- Output Signal: 4-20mA (2 wire)

- Accuracy: 0.35% 0.4bar range & above, 0.5% below

- Electrical Connection: DIN43650A plug IP65

- Process Connection: G1/2 Flush DIN3852, 1bar & above

- Process Connector Material: Stainless steel 316L

- Diaphragm Material: Stainless Steel 316L

- Media & Temperature: 200degC, Vac < 150degC, FKM seal

Using oil filled sensors in food processing

Why do some pressure measurement devices need to have a food grade oil filling?

The majority of pressure sensing devices which include an oil filled capsule have a thin isolation diaphragm containing a silicone oil filling. The silicon oil provides the pressure transfer medium between the process media and sensing element.

If the isolation diaphragm fails for whatever reason, the oil may leak into the process contaminating the product being processed. In food processing, any substance that might contaminate the process, must be harmless if consumed.

Standard silicone oil is not food compatible, and therefore some manufacturers will offer an alternative oil fill such as peanut oil, vegetable oil or a food grade silicone oil to make their products suitable for the food and drink industry.

Withstand 400°F to measure 130 psi steam pressure

We are plant based food processing company and we need a pressure transducer to measure 0-130PSI steam which can tolerate temperatures up to 400 degF, would the DMP 331 P be able to do this?

A DMP 331 P fitted with the 300°C cooling element will allow you use the sensor on steam at 400°F, and since the application is on food we would recommend a food grade oil fill behind the isolation diaphragm as a precaution to protect the process from contamination.

- SKU ID: s1-dmp331p-0001

- Part No: 500-1002-1-3-100-Z00-1-2-200

- Pressure Range: 0 to 10

- Units: bar

- Range Type: Positive Gauge (atm to +P)

- Output Signal: 4-20mA (2 wire)

- Electrical Connection: DIN43650A plug IP65

- Process Connection: G1/2 Flush DIN3852, P>=1bar only

- Process Connector Material: Stainless steel 316L

- Diaphragm Material: Stainless Steel 316L

- Media & Temperature: Food grade, 200degC max, Vac<150degC, FKM seal

Related Documents

Specification data sheet

Request Product Price

Please select the options you require for the DMP331P Hygienic Flush Pressure Transmitter in your application and request a quote.