Pressure sensors with open flush diaphragms suitable for use with highly viscous media such as plastics, paper pulp, bitumen, sewage, paint and adhesives.

These high viscosity fluid pressure sensors can be cleaned if there is a build up of residue around the process connection because there are no hidden voids and all surfaces in contact with the viscous fluid are accessible.

Products

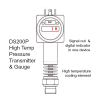

DS200P Sanitary Low Range Pressure Gauge, Switch and Sensor - All in one electronic switch, gauge and sensor designed specifically for use in the food, drink and biomedical industry for measuring process pressures.

DS200P Sanitary Low Range Pressure Gauge, Switch and Sensor - All in one electronic switch, gauge and sensor designed specifically for use in the food, drink and biomedical industry for measuring process pressures. DMP331P Hygienic Flush Pressure Transmitter - Sanitary pressure sensor wth exposed diaphragm with no crevices for high temperatures up to 300 Degrees Celsius in ranges from 100mb up to 40 bar gauge or absolute

DMP331P Hygienic Flush Pressure Transmitter - Sanitary pressure sensor wth exposed diaphragm with no crevices for high temperatures up to 300 Degrees Celsius in ranges from 100mb up to 40 bar gauge or absolute

LMK 487 Submersible Ballast Tank and Draught Level Pressure Transmitter

LMK 487 Submersible Ballast Tank and Draught Level Pressure Transmitter LMK387 Cleanable Sewage and Sludge Pressure/Level Sensor

LMK387 Cleanable Sewage and Sludge Pressure/Level Sensor DMK331P Flush Diaphragm Pressure Sensor

DMK331P Flush Diaphragm Pressure Sensor DCT531P RS485 Modbus RTU Flush Pressure Sensor

DCT531P RS485 Modbus RTU Flush Pressure Sensor

Applications

Diaphragm sealed high temperature pressure transmitter for -1 to 25 kg/cm² - Diaphragm sealed pressure transmitter for measuring over -1 to 25 kg/cm² on liquid with a flush type diaphragm up to a temperature of 190°C.

Diaphragm sealed high temperature pressure transmitter for -1 to 25 kg/cm² - Diaphragm sealed pressure transmitter for measuring over -1 to 25 kg/cm² on liquid with a flush type diaphragm up to a temperature of 190°C. Blow moulding machine 10,000 psi GRAS NaK filled 10V melt pressure sensor - Plastic melt pressure sensor with a GRAS compliant NaK filling fluid, 10,000 psi high pressure range and 0 to 10 Vdc output signal for use on blow moulding machines.

Blow moulding machine 10,000 psi GRAS NaK filled 10V melt pressure sensor - Plastic melt pressure sensor with a GRAS compliant NaK filling fluid, 10,000 psi high pressure range and 0 to 10 Vdc output signal for use on blow moulding machines. Food processing freshwater transfer pump 4 barg 4-20mA pressure sensor - A hygienic stainless steel flush diaphragm gauge pressure sensor for food processing pump transfer system to measure pressure of freshwater over a range of 0 to 4 bar g from the tri-clamp process connection, and sending the corresponding 4-20mA signal through the M12 connector electrical connection.

Food processing freshwater transfer pump 4 barg 4-20mA pressure sensor - A hygienic stainless steel flush diaphragm gauge pressure sensor for food processing pump transfer system to measure pressure of freshwater over a range of 0 to 4 bar g from the tri-clamp process connection, and sending the corresponding 4-20mA signal through the M12 connector electrical connection. 60psig range pharmaceutical pressure gauge and 0-10Vdc transducer with triclamp fitting - Digital display pressure gauge for portable use in pharmaceutical measurement applications, capable of measuring 0 to 60 psi g pressure with 0.5% accuracy and connected using a triclamp fitting. Also includes a 0-10Vdc output, hygienic fitting and cal cert.

60psig range pharmaceutical pressure gauge and 0-10Vdc transducer with triclamp fitting - Digital display pressure gauge for portable use in pharmaceutical measurement applications, capable of measuring 0 to 60 psi g pressure with 0.5% accuracy and connected using a triclamp fitting. Also includes a 0-10Vdc output, hygienic fitting and cal cert.

6 bar absolute range 4-20mA output high temperature epoxy resin pressure sensor for research use

6 bar absolute range 4-20mA output high temperature epoxy resin pressure sensor for research use 50-70 psi g range freshwater compatible 0-10V signal out pressure sensor for water treatment use

50-70 psi g range freshwater compatible 0-10V signal out pressure sensor for water treatment use Water reclamation system 6 bar range pressure transmitter for marine use

Water reclamation system 6 bar range pressure transmitter for marine use Flush mountable vacuum transmitter

Flush mountable vacuum transmitter G1/2 flush 60 psig pressure transmitter for thick liquids in Ex zones

G1/2 flush 60 psig pressure transmitter for thick liquids in Ex zones 200 degC media temperature pressure sensor with 25 bar g range and 0 to 10 volts output

200 degC media temperature pressure sensor with 25 bar g range and 0 to 10 volts output 10 psi g range flush diaphragm stainless steel 316L pressure transmitter

10 psi g range flush diaphragm stainless steel 316L pressure transmitter 50 kPa negative gauge vacuum transmitter for Milk

50 kPa negative gauge vacuum transmitter for Milk

- 90 psi g air pressure transducer for food processes up to 200 degC

- 1000 mbar vacuum transmitter for use with waste toner dust

- Ranges below 60 bar no longer available for DMK331P

- Powder filter blockage monitoring pressure transmitter

- Submersible sensor for measuring sludge pressure in pipe

- 5000 psi g flush all stainless steel 316L pressure transmitter

- 160 bar g pressure transmitter for use with high temperature media up to 300 degC