Ultrasound acoustic wave fluid flow velocity sensors.

Ultrasonic sensors are contactless measurement devices which transmit and receive high frequency acoustic waves to measure flow velocity of a fluid.

Since there is no contact with the fluid to be measured, ultrasound sensor technology can be used in applications where sensors requiring contact are otherwise prohibited. These sensors have no moving parts which makes them very reliable, requiring very little maintenance.

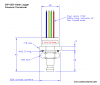

Ultrasonic sensors can be housed in a single assembly combining the acoustic transmitter and receiver in one device, or in dual assembly separating the acoustic transmitter and receiver.

Featured flow measurement products

250″wc Orifice plate flow measurement dp transmitter - This differential pressure (dp) transmitter can be used to measure the difference in upstream and downstream flowing pressure either side of a orifice plate.

250″wc Orifice plate flow measurement dp transmitter - This differential pressure (dp) transmitter can be used to measure the difference in upstream and downstream flowing pressure either side of a orifice plate. 10 kPa orifice plate differential pressure transmitter for water flow measurement - Pressure sensor for measuring the differential pressure generated by water flowing through an orifice plate in a pipe, and converting the output to a water flow measurement.

10 kPa orifice plate differential pressure transmitter for water flow measurement - Pressure sensor for measuring the differential pressure generated by water flowing through an orifice plate in a pipe, and converting the output to a water flow measurement.

Glossary of Sensor Technology technical terms

- BFSG – Bonded Foil Strain Gauge

- Bourdon Tube

- Capacitive Fluid Level Measurement

- Ceramic Pressure Sensors

- Conductive Fluid Level Detection

- Doppler Effect Flow Measurement

- Float Fluid Level Detection

- LVDT – Linear Variable Differential Transformer

- Paddle Wheel Sensor

- Piezoresistive Strain Gauges

- Positive Displacement Flow Measurement

- Radar Distance Sensing

- SOI – Silicon on Insulator

- Strain Gauge

- Thin Film

- Transit Time Flow Measurement

- Turbine Rotor Sensor

- Ultrasonic Distance Sensing

- Vibrating Tuning Fork Fluid Level Detection

- Vortex Flow Measurement

- Wheatstone Bridge Strain Gauge