High range pressure data recorders for saving high pressure readings to create a data record over a specified time period.

Products

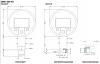

DM01-500-HD High Range Digital Pressure Gauge - The DM01-500 HD high range pressure gauge is available in pressure ranges from 0 to 600, 1000, 1600, 2000 & 2200 bar.

DM01-500-HD High Range Digital Pressure Gauge - The DM01-500 HD high range pressure gauge is available in pressure ranges from 0 to 600, 1000, 1600, 2000 & 2200 bar. LEO Record (Ei) Pressure Data Logger - LEO Record combined digital manometer & pressure data logging instrument for recording pressures & temperatures that can store up to 57,000 readings.

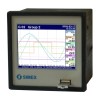

LEO Record (Ei) Pressure Data Logger - LEO Record combined digital manometer & pressure data logging instrument for recording pressures & temperatures that can store up to 57,000 readings.

Applications

Hydraulic puller-tensioner bar pressure to kilonewton load HMI display & logger - We are looking for an indicator with HMI software to show a machine operator the amount of force generated by a hydraulic puller-tensioner used for power line stringing.

Hydraulic puller-tensioner bar pressure to kilonewton load HMI display & logger - We are looking for an indicator with HMI software to show a machine operator the amount of force generated by a hydraulic puller-tensioner used for power line stringing. 700 barg natural gas high range pressure gauge logger with 1/2 NPT male fitting - Digital display high pressure gauge for pipe mounted use in natural gas measurement applications, capable of measuring 0 to 700 bar g pressure with 0.1% accuracy and connected using a 1/2 NPT male fitting. Also includes USB, logger, log software and cal cert.

700 barg natural gas high range pressure gauge logger with 1/2 NPT male fitting - Digital display high pressure gauge for pipe mounted use in natural gas measurement applications, capable of measuring 0 to 700 bar g pressure with 0.1% accuracy and connected using a 1/2 NPT male fitting. Also includes USB, logger, log software and cal cert.

1000 bar PC logging pressure gauge for connecting to computer USB port

1000 bar PC logging pressure gauge for connecting to computer USB port Recordable indicator and sensor up to 30000 psi for pressure test rig

Recordable indicator and sensor up to 30000 psi for pressure test rig 40,000 psi pressure sensor and data logger

40,000 psi pressure sensor and data logger 30,000 psi pressure sensor with recording indicator for data acquisition

30,000 psi pressure sensor with recording indicator for data acquisition

- 10000 psi Digital Pressure Gauge with Memory Storage

- 50,000 psi logger, indicator and sensor for hose burst testing

- 15,000 psi intrinsically safe high pressure logger

- 1600 bar data acquisition and recording system

- 5000 psi data logging gauge for measuring hydraulic pressures

- 4500 psi digital pressure gauge with datalogging