Digital pressure gauges combined with a programmable data logger for recording pneumatic or hydraulic pressures at set time periods.

Designed to be remotely installed on a process pipe or vessel for monitoring process performance or testing for leaks.

Field portable pressure indicators that have the optional capability to store pressure data for recalling on the display screen or transferring to a computer at a later time.

Each data point is time and date stamped for compliance with quality audit trail procedures.

Products

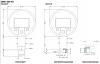

DM01 Multi-Range High Accuracy Pressure Gauge - High precision digital pressure gauge with 0.05% full scale accuracy, exchangeable pressure range modules from 100 mbar (1.5 psi) up to 400 bar (6000 psi).

DM01 Multi-Range High Accuracy Pressure Gauge - High precision digital pressure gauge with 0.05% full scale accuracy, exchangeable pressure range modules from 100 mbar (1.5 psi) up to 400 bar (6000 psi). DM01-500-HD High Range Digital Pressure Gauge - The DM01-500 HD high range pressure gauge is available in pressure ranges from 0 to 600, 1000, 1600, 2000 & 2200 bar.

DM01-500-HD High Range Digital Pressure Gauge - The DM01-500 HD high range pressure gauge is available in pressure ranges from 0 to 600, 1000, 1600, 2000 & 2200 bar.

Applications

500 kPa g range rupture disk blowing digital display pressure gauge and logger - Digital display pressure gauge for pipe mounted use in applications to monitor blowing of rupture disks, capable of measuring 0 to 500 kPa g pressure with 0.05% accuracy and connected using a 1/2 NPT male fitting. Also includes USB, logger, peak hold, log software and traceable cal cert.

500 kPa g range rupture disk blowing digital display pressure gauge and logger - Digital display pressure gauge for pipe mounted use in applications to monitor blowing of rupture disks, capable of measuring 0 to 500 kPa g pressure with 0.05% accuracy and connected using a 1/2 NPT male fitting. Also includes USB, logger, peak hold, log software and traceable cal cert. Hydraulic puller-tensioner bar pressure to kilonewton load HMI display & logger - We are looking for an indicator with HMI software to show a machine operator the amount of force generated by a hydraulic puller-tensioner used for power line stringing.

Hydraulic puller-tensioner bar pressure to kilonewton load HMI display & logger - We are looking for an indicator with HMI software to show a machine operator the amount of force generated by a hydraulic puller-tensioner used for power line stringing.

30 inHg low relative vacuum range digital display vacuum pressure gauge and logger

30 inHg low relative vacuum range digital display vacuum pressure gauge and logger 100 mbar g low range air pressure gauge and logger with G1/4 male fitting

100 mbar g low range air pressure gauge and logger with G1/4 male fitting 700 barg natural gas high range pressure gauge logger with 1/2 NPT male fitting

700 barg natural gas high range pressure gauge logger with 1/2 NPT male fitting 1000 bar PC logging pressure gauge for connecting to computer USB port

1000 bar PC logging pressure gauge for connecting to computer USB port

- 30 ounces per square inch range pressure gauge with built-in logger

- 10 psi vacuum air and 50 psi water pressure gauge and data logger

- 5000 psi data logging gauge for measuring hydraulic pressures

- 6000 psi recording digital pressure gauge with intrinsic safety

Product Types

Keller Digital Manometers - Keller manufactured digital manometers for measuring and displaying pressure readings in different engineering units.

Keller Digital Manometers - Keller manufactured digital manometers for measuring and displaying pressure readings in different engineering units.