Ultra low differential pressure sensor for HVAC applications with 4-20mA current loop or amplified voltage output signal in pressure ranges from 0.1 mb up to 1 bar differential.

DPS very low differential pressure transducer is an affordable option for measuring the differential pressure of airflow on heating, cooling, ventilation & air conditioning (HVAC) systems in buildings, laboratories, cleanrooms & factories.

The DPS ultra low differential pressure transmitter can also be used for measuring filter condition and ensuring a differential pressure between two rooms.

Product Parameters

- Pressure Ranges: 10 Pa to 100 kPa differential

- Static Line Pressure: 1 bar gauge max

- Accuracy: 1% FS non-linearity with 0.1% FS hysteresis

- Output Signals: 0-10V, 4-20mA or 0-20mA

- Sensor Supply Voltage: 19-31Vdc, 12-32Vdc (2 wire only), 24Vdc isolated, 24Vac & 230Vac

- Electrical Connection: 2 enclosure cable glands M12 x1.5 with 5 internal screw terminals

- Pressure Connections: 6.6mm dia x 11mm barbed push on connections for 6mm dia flexible tubing or clamp ring tube fitting 1/8 inch MS

- Environmental Protection: IP54

- Media Compatibility: Non aggressive gases, Ni, Al, CuBe, PU, silicon rubber

- Dimensions: 120 x 80 x 55mm, larger dimensions with relay switch and auto-valve overpressure protection options

- Weight: 300 – 400g

- Special Options: Integrated LCD display, Alarm relay outputs

Product Description

Applications

The DPS low differential pressure transducer is an affordable sensor for measuring air-flow differential pressure in the following locations & applications:

- Semiconductor processing clean-rooms

- Pharmaceutical research laboratories

- Building ventilation air ducts

- Factory air conditioning

- Hospital operating theatres

- Anteroom to pharmacy hood room

- Blocked air filter

Sensing principle

This economical HVAC pressure transmitter relies on wear-free inductive coupling technology to detect fractional movements in the sensing diaphragm. This sensing technology provides a highly stable and reliable method for sensing low pressures.

Low Pressure Ranges

The DPS low differential pressure transmitter can be specified in ranges starting from as low as 10 pascals up to 1 bar which covers a wide range of applications whether you are controlling the differential pressure between two rooms, measuring the differential pressure in a ventilation duct, or detecting the condition of an air filter.

Accuracy

The DPS clean-room dp pressure sensor has a standard linearity of ±1% full scale with improved linearity options of ±0.5% FS & ±0.2% FS, the pressure hysteresis is better than ±0.1% full scale. Despite the low pressure range a good stability figure of ±0.5% FS per year is typically achieved.

Output signal

The signal conditioning electronics of the DPS low range diff pressure transducer provide options for a 5 or 10 Volt DC output or a 4-20mA current output in either 3 wire or 2 wire configuration. The supply voltage can be 24Vdc, 230Vac or 115Vac mains providing flexibility for different air control systems.

Integral display

If a local readout of pressure is required an LCD display can be integrated into the DPS differential air pressure sensors enclosure.

Auto-zero offset

An auto-zeroing feature for calibration purposes plus relay switch outputs for triggering an alarm are also available options along with the local display.

Product Applications

Containment cabinet exhaust pressure

Monitoring exhaust fan duct static pressure from a ventilated gas tank containment cabinet in a laboratory environment.

- SKU ID: s1-dps-0005

- Pressure Range: 0-5

- Units: inH2O

- Range Type: Differential (0 to +P)

- Output Signal & Supply Type: 4-20mA 2 wire, 12-32Vdc supply

- Output Options: Linear signal

- Accuracy (linearity only): 1% full scale

- Electrical Connection: M12 x 1.5 cable glands with 5 internal screw terminals

- Process Connection: 6.6mm dia x 11mm barbed connections

- Media Compatibility: Non aggressive gases compatible with Ni, Al, CuBe, PU, silicon rubber

Lab & corridor pressure difference

Measure the pressure difference between a lab and the corridor door to ensure a positive or negative pressure difference.

- SKU ID: s1-dps-0004

- Pressure Range: -50 to +50

- Units: Pa

- Range Type: Bi-Directional Differential (-P to +P)

- Output Signal & Supply Type: 0-10V 4 wire, 24Vac supply

- Output Options: Linear signal

- Accuracy (linearity only): 1% full scale

- Electrical Connection: M12 x 1.5 cable glands with 5 internal screw terminals

- Process Connection: 6.6mm dia x 11mm barbed connections

- Media Compatibility: Non aggressive gases compatible with Ni, Al, CuBe, PU, silicon rubber

- Optional Extras: Integrated LCD display, 3 1/2 digit

DPF cleaning machine

Monitoring the backpressure of Diesel particulate filter cleaning machine backpressure.

- SKU ID: s1-dps-0001

- Pressure Range: 250

- Units: mbar

- Range Type: Differential (0 to +P)

- Output Signal & Supply Type: 0-10V 3 wire, 19-31Vdc supply

- Output Options: Linear signal

- Accuracy (linearity only): 1% full scale

- Electrical Connection: M12 x 1.5 cable glands with 5 internal screw terminals

- Process Connection: 6.6mm dia x 11mm barbed connections

- Media Compatibility: Non aggressive gases compatible with Ni, Al, CuBe, PU, silicon rubber

Product Help

60 seconds switch activation delay

We are ideally looking for a delay of 60 secs for activation of the switch after the threshold pressure has been reached, is this achievable?

The relay switches on the DPS have a maximum switching delay of up to 10 seconds. If you need to do a 60 second or more delay then we would suggest excluding the switch contacts option on the DPS, and instead take the output signal from the DPS to a SRP-N118 for example. This wall mounted display unit includes a re-transmission analogue output and 2 x relay contact switches which can be set to delay switching from 0.1 seconds through to 99 minutes.

0.035 inWG measurement

I am looking for a differential pressure transducer that has the capability of controlling a damper via 4-20Ma output signal in order to maintain .035 in w.c.

We would suggest the 0.4 in w.c. range DPS.

- SKU ID: s1-dps-0003

- Pressure Range: 0.4

- Units: inH2O

- Range Type: Differential (0 to +P)

- Output Signal & Supply Type: 4-20mA 2 wire, 12-32Vdc supply

- Output Options: Linear signal

- Accuracy (linearity only): 1% full scale

- Electrical Connection: M12 x 1.5 cable glands with 5 internal screw terminals

- Process Connection: 6.6mm dia x 11mm barbed connections

- Media Compatibility: Non aggressive gases compatible with Ni, Al, CuBe, PU, silicon rubber

Overpressure effects on 100Pa range

What happens to the DPS pressure transmitter if the pressure exceeds a full scale range of 100 Pa with an overload limit of 500 Pa?

0-500 pascals – Up to the full scale pressure of 500 Pa, nothing will happen to the pressure cell.

500 to 1000 pascals – Between 500 and 1000 Pa, the calibration of the pressure sensor may be affected.

1000 pascals and above – If the pressure goes higher than 1000 Pa, the pressure cell may be damaged.

DPS vs DPS200

What is the main difference between the DPS and DPS200 low range differential pressure sensors?

The DPS200 is lower cost but the DPS has ranges as low as 0 to 10 pascals.

Also the DPS can be specified with extra features and functions that are not available on the DPS200 such as:

- AC Power supply

- Wider choice of output configurations

- Square root extraction output

- High overpressure protection

- Linearity accuracy improvements

- Alarm relay contact switch

Vacuum switch to verify down to -1000 Pa

I’m looking for a pressure transmitter for a vacuum application, the aim is to verify the pressure inside a little vacuum chamber with a min pressure of -1000 Pa relative to atmosphere. I also need switches which are programmable?

We would suggest a 1000 Pa differential range, and if you connect the vacuum chamber to the negative port the output will be proportional to amount of suction, i.e. 0 volts at atmospheric pressure and 10 volts at -1000 pascals. It is possible to supply the DPS with 2 separate voltage free relay contact switches, which are adjustable via the potentiometers inside the sensor.

- SKU ID: s1-dps-0002

- Pressure Range: 0 to 1000

- Units: Pa

- Range Type: Differential (0 to +P)

- Output Signal & Supply Type: 0-10V 3 wire, 19-31Vdc supply

- Output Options: Linear signal plus 2 relay contact switches

- Accuracy (linearity only): 1% full scale

- Electrical Connection: M12 x 1.5 cable glands with 5 internal screw terminals

- Process Connection: 6.6mm dia x 11mm barbed connections

- Media Compatibility: Non aggressive gases compatible with Ni, Al, CuBe, PU, silicon rubber

Setting up alarm relay switch contacts

How do the alarm relay outputs work on the DPS low differential pressure transmitter?

The alarm relay outputs are internal voltage free contacts that are opened and closed when a threshold pressure is reached. The threshold pressure can be adjusted using the adjustment trim pots inside the sensor enclosure.

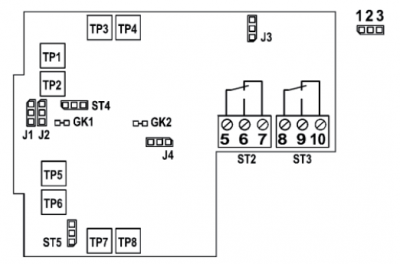

Adjustment Controls

TP 1: Potentiometer for limit contact 1 (GK1)

TP 2: Potentiometer for hysteresis (limit contact 1)

TP 3: Potentiometer for turn-on delay (limit contact 1)

TP 4: Potentiometer for turn-off delay (limit contact 1)

TP 5: Potentiometer for limit contact 2 (GK2)

TP 6: Potentiometer for hysteresis (limit contact 2)

TP 7: Potentiometer for turn-on delay (limit contact 2)

TP 8: Potentiometer for turn-off delay (limit contact 2)

J 1: Jumper for positive or negative pressure range for limit contact 1

J 2: Jumper for positive or negative pressure range for limit contact 2

J 3: Jumper for relay function limit contact 1

J 4: Jumper for relay function limit contact 2

ST4: Connection for digital multimeter for adjustment of limit contact 1

ST5: Connection for digital multimeter for adjustment of limit contact 2

GK1: LED for limit contact 1

GK2: LED for limit contact 2

Adjustment of the limit contacts

Prior to adjusting the limit contacts first connect the supply voltage according to the sensor type label.

Limit Contact 1 (2)

J1 (J2) has two possible jumper settings to close the switch in the positive or negative pressure direction.

- Link pin 1 + 2 for positive pressure alarm

- Link pin 2 + 3 for negative pressure alarm

J3 (J4) has two possible jumper settings to set either the maximum limit or the minimum limit.

- Link pin 1 + 2 for max. pressure limit

- Link pin 2 + 3 for min. pressure limit

TP1 (T5) is the trimming potentiometer to set the switch limit from 0 to 100% of positive or negative pressure.

TP2 (T6) is the trimming potentiometer to set the switching hysteresis from 0 to 100%.

ST4 (ST5) provides the connection for a multimeter to calibrate TP1 (TP5) and TP2 (TP6) settings.

Link multimeter across pin 1 + 3 of ST4 (ST5) to measure the TP1 (TP5) setting where a measurement from 0 to 1 volt directly relates to the 0 to 100% setting.

Lin multimeter across pin 1 + 2 of ST4 (ST5) to measure the TP2 (TP6) setting where a measurement from 0 to 0.5 volt relates to 0 to the 100% setting.

As soon as the pressure reaches the limit value setting, the relay responds and the Led for GK1 (GK2) is illuminated.

Using trimmer TP3 (TP7) a turn-on delay between 0 and 10 seconds can be set for limit contact 1. The left limit of the trimmer corresponds to a turn-on delay of 0 seconds and the right limit corresponds to a 10 second delay.

Using trimmer TP4 (TP8) a turn-off delay between 0 and 10 seconds can be set for limit contact 1. The left limit of the trimmer corresponds to a turn-off delay of 0 seconds and the right limit corresponds to a 10 second delay.

Adjustment using pressure calibrator

Adjustment of the limit contacts can also be carried out using a pressure source such as pressure calibrator type TGP2.

First set the trimmer of the timing element to the left limit so as to zero all timing circuits. Then set the pressure of the

pressure calibrator to the required switching value.

Adjust trimmer TP1 for GK1 (TP5 for GK2) until LED GK1 (GK2) illuminates.

Then using the pressure calibrator set the pressure to the value required to reswitch the relay. Then adjust potentiometer TP2 for GK1 (TP6 for GK2) until LED GK1 (GK2) goes off.

Adjust the delay times as described above.

Intrinsically safe version

Is there an intrinsically safe version or ATEX Zone 1 version of the DPS low differential pressure transmitter?

The lowest range we offer with ATEX approval is the XMD with a 0-75 mbar differential range which can be adjusted to a minimum scaling of 0-7 mbar.

Clean room positive air pressure monitoring

We are in the process of setting up a small clean room, which we wish to maintain with a positive air pressure compared with adjacent rooms. The room has extraction and make up air. What would you suggest for monitoring the pressure between adjacent rooms?

Typically the difference in air pressure is very small between rooms and it is best monitored by using a device such as the DPS which is a low differential air pressure sensor. The DPS has a choice of pressure ranges to cover most applications in clean rooms.

Related Documents

Specification data sheet

Request Product Price

Please select the options you require for the DPS Low Differential Pressure Transmitter in your application and request a quote.