IP68-rated underwater pressure sensors designed for continuous submersion. Ideal for ballast tank level, subsea system monitoring, and hollow structure flood detection.

Underwater pressure sensors are robust instruments meticulously designed for continuous and reliable operation while fully submerged, often to significant depths. Characterized by their IP68 rating, which specifies their protection against water ingress up to a defined maximum depth, these sensors are crucial for a variety of subsea applications. They play a vital role in monitoring water levels within submerged hollow structures, precisely measuring fluid levels in ballast tanks for buoyancy control, gauging ballast tank blow pressures, and overseeing the integrity of pressurized underwater pipework and vessels. Their construction prioritizes corrosion-resistant materials and sealed designs to ensure accuracy and longevity in challenging marine or industrial aquatic environments.

300 foot sea depth waterproof pressure sensor with 0-5V signal - Waterproof submersible pressure sensor for lowering to ~300 feet below sea level.

300 foot sea depth waterproof pressure sensor with 0-5V signal - Waterproof submersible pressure sensor for lowering to ~300 feet below sea level. Irrigation water pressure transducer for pressures up to 60 bar - Voltage output pressure transducer with a 0 - 5V dc signal out for measuring irrigation piping water pressure form 0-60bar.

Irrigation water pressure transducer for pressures up to 60 bar - Voltage output pressure transducer with a 0 - 5V dc signal out for measuring irrigation piping water pressure form 0-60bar.

DMK457 Marine Approved Pressure Transmitter

DMK457 Marine Approved Pressure Transmitter LMK387 Cleanable Sewage and Sludge Pressure/Level Sensor

LMK387 Cleanable Sewage and Sludge Pressure/Level Sensor SSPT Subsea Wet-Mateable Electrical Connector Pressure Sensor

SSPT Subsea Wet-Mateable Electrical Connector Pressure Sensor LMK 487 Submersible Ballast Tank and Draught Level Pressure Transmitter

LMK 487 Submersible Ballast Tank and Draught Level Pressure Transmitter

- Detecting water intake blockage on submerged reservoir intake screen using two sensors - Discover a robust solution for measuring head loss and detecting ice blockages on remote water intake screens. Learn how dual submersible pressure transmitters with 4-20mA outputs overcome long-distance signal transmission challenges in reservoir monitoring.

- Monitoring high-pressure seawater pumps on merchant vessels with submersible pressure transmitters - Monitoring high-pressure seawater pump performance in marine washing systems. Submersible, corrosion-resistant pressure transmitters provide reliable measurements for both inlet and outlet pressures.

- Marine air lubrication system submersible seawater resistant air pressure transmitter - Measuring gauge air pressure inside a pipe near an underwater air injector for a ship's drag reduction system. Marine grade pressure sensors provide essential accuracy and seawater resistance for reliable component testing and performance tuning at depths down to 10 meters.

- Low power fast response differential pressure sensing for IoT water network logging - Monitoring water pressure in utility networks with low-power IoT data loggers with a fast-response, IP68 submersible sensor to meet critical power consumption and potable water compatibility requirements.

Waterproof Absolute Pressure Sensors - Discover robust waterproof absolute pressure sensors, ideal for reliable underwater pressure and level measurement where vented sensors are impractical. Learn how readings convert to gauge pressure. Suited for subsea, borehole, and marine deployments.

Waterproof Absolute Pressure Sensors - Discover robust waterproof absolute pressure sensors, ideal for reliable underwater pressure and level measurement where vented sensors are impractical. Learn how readings convert to gauge pressure. Suited for subsea, borehole, and marine deployments. IP68 Submersible Protected Voltage Output Signal Pressure Transducers - Explore IP68 submersible pressure transducers with voltage outputs (0-5V/0-10V) for continuous underwater level and pressure measurement in tanks, boreholes, and rivers. Vented gauge and absolute options available.

IP68 Submersible Protected Voltage Output Signal Pressure Transducers - Explore IP68 submersible pressure transducers with voltage outputs (0-5V/0-10V) for continuous underwater level and pressure measurement in tanks, boreholes, and rivers. Vented gauge and absolute options available. Submersible Pressure Transmitters - Submersible pressure transmitters offer reliable and accurate measurements in challenging underwater environments. With 4-20mA output and IP68 ratings, these robust sensors excel in monitoring liquid level, water depth, and pressure in submerged applications.

Submersible Pressure Transmitters - Submersible pressure transmitters offer reliable and accurate measurements in challenging underwater environments. With 4-20mA output and IP68 ratings, these robust sensors excel in monitoring liquid level, water depth, and pressure in submerged applications. Water Resistant Pressure Sensors with Strain Gauge Output - Explore our range of submersible pressure sensors engineered with strain gauge technology. These sensors excel in demanding underwater environments, offering accurate hydrostatic level measurements and reliable pressure readings for submerged systems.

Water Resistant Pressure Sensors with Strain Gauge Output - Explore our range of submersible pressure sensors engineered with strain gauge technology. These sensors excel in demanding underwater environments, offering accurate hydrostatic level measurements and reliable pressure readings for submerged systems.

Find out more about Underwater Pressure Sensors to determine which product options and capabilities will best meet your application requirements.

Underwater pressure sensors are specifically engineered for continuous operation while submerged, featuring robust construction designed to meticulously prevent water ingress into sensitive electronic components, thereby averting damage and ensuring long-term reliability. A critical design characteristic of these sensors is their Ingress Protection rating, typically IP68, which certifies their suitability for permanent immersion. This rating is always accompanied by a specified maximum water depth, a crucial parameter dictating the pressure the sensor housing and seals can withstand without compromise. The materials selected for the sensor body and wetted parts, such as specific grades of stainless steel (e.g., 316L), titanium, or marine bronze, are chosen for their corrosion resistance, especially in saline or chemically active underwater environments.

One key application involves monitoring the water level within hollow sub-surface structures, such as the foundations of bridges, offshore platform supports, or submerged sections of tunnels and caissons. In these scenarios, water seepage can compromise structural integrity or damage internal equipment. An underwater pressure sensor is typically installed at the lowest practical point on the structure’s exterior, or internally if a suitable penetration point exists, to measure the hydrostatic head of accumulated water. This data allows for timely intervention, such as activating dewatering systems, to maintain the structure’s safety and operational integrity. The sensor’s output, directly proportional to the water height, provides continuous insight into the internal flood status.

Ballast tanks, essential for controlling the buoyancy of submarines, remotely operated vehicles (ROVs), autonomous underwater vehicles (AUVs), ships, and floating platforms, rely heavily on precise level measurement. Underwater pressure sensors are commonly mounted externally at the bottom of these tanks. They measure the hydrostatic pressure exerted by the column of water inside the tank, allowing for accurate calculation of the water volume and, consequently, the current buoyancy state. This information is vital for navigation, stability, and operational control of the submerged or floating equipment. The sensor’s ability to withstand external ambient water pressure while accurately reading internal tank pressure is a key design consideration.

In conjunction with level measurement, managing the “blow pressure” within ballast tanks is another critical function addressed by underwater pressure sensors. Compressed air or other gases are used to displace water from the tanks, thereby increasing buoyancy, or vented to allow water ingress, decreasing buoyancy. Sensors designed for this purpose are often installed on the external top surface of the ballast tank, or integrated into the pneumatic control system, to measure the pressure of the air or gas pocket above the water level. This allows for precise control over the filling and emptying process, ensuring efficient buoyancy adjustments and preventing over-pressurization of the tank structure.

Beyond level and buoyancy control, underwater pressure sensors are indispensable for monitoring the operational integrity of various submerged pressurized systems. This includes subsea hydraulic control systems, underwater segments of oil and gas pipelines, deep-sea research equipment, and even hyperbaric chambers. In these applications, the sensor is fitted externally to the pipework, vessel, or equipment housing to directly measure the internal working pressure. The ability to obtain these pressure readings without compromising the integrity of the pressurized system, often in challenging deep-water environments, provides crucial data for safety monitoring, leak detection, and system performance analysis. The sensor’s design must account for both the internal system pressure and the external ambient water pressure.

The reliability of the electrical connection is paramount for underwater pressure sensors. Specially designed submersible cables and glands are employed, ensuring a watertight seal against the operational pressures at depth. 1 These cable assemblies must resist physical abrasion, chemical attack, and the effects of long-term immersion. For applications involving level measurement via hydrostatic pressure, the sensor might be a sealed gauge type, referenced to a pre-set atmospheric pressure, or an absolute pressure sensor where barometric pressure variations are either negligible or compensated for. In some shallower applications, vented gauge sensors with a vent tube incorporated into the submersible cable can provide direct atmospheric referencing, though this introduces a potential ingress path if not meticulously managed. The choice of pressure reference and sensor type is a critical engineering decision based on the specific application, required accuracy, and depth of deployment.

Product Uses

Applications that use underwater pressure sensors.

Level of water inside hollow structure below water line

There many types of structures permanently fixed to the seabed or river bend, and some of these structures have a hollow interior. Since there maybe equipment below the water surface line or concerns over long term corrosion of the internal structure, it is necessary to monitor and control the level of any water that has seeped into the structure. A pressure sensor is fitted to the outer case of the underwater structure at the lowest necessary point to measure the head of water above that point that has accumulated in the hollow space.

Ballast tank level measurement

Ballast tanks are fitted to underwater equipment and structures to control buoyancy. Pressure sensors are fitted to the external bottom surface of the ballast tank underwater to measure the head pressure of water inside the ballast tank, which is used to calculate the quantity of water and ultimately the amount of buoyancy.

Ballast tank blow pressure

Compressed air or other gas is used to control the level of water in a ballast tank. To reduce the water level the air pressure is raised, and likewise air pressure is lowered to increase the water level. Pressure sensors are fitted to the external top surface of ballast tanks to measure the air pocket inside the ballast tank.

Pressurised pipework, vessel and systems

Where there is a pressurised equipment underwater, it is often required to monitor the pressure directly, and this may require the fitting a pressure sensor externally underwater to measure the working pressure.

Product Help

Help with selecting, installing and using underwater pressure sensors.

Depth rating

Make sure it will remain watertight at the required depth.

An underwater pressure sensor should have an IP68 rating for permanent immersion, and be rated to the required depth or external pressure.

Surface cable length

Don’t forget to consider the cable length required above out of the water.

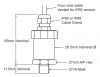

If the sensor cable is run to the water surface, ensure that you leave enough cable to reach the surface plus the necessary length of cable to reach the termination point. When specifying a pressure sensor it’s very easy to mistakenly select a cable length that corresponds to the required depth and not account for the extra cable required to make the link to the surface instrumentation which could be several metres away from the location where the cable runs below the surface.

Removable cable connection

Always follow the manufacturer’s procedure for breaking and re-making an underwater cable connector.

Follow installation instructions precisely when using a removable cable assembly, since underwater proofing maybe compromised if incorrectly fitted. During the service life of a re-mountable submersible cable connection, it is sometimes necessary to disconnect the watertight connection for various reasons, such as replacing the pressure sensor or cable assembly. When the connection is re-made it is important that you follow the advice in the operation manual to ensure the best chance retaining the integrity of the underwater seal. This submersible IP rated seal is only guaranteed if you follow the re-fitting procedure precisely.

Material selection

Water often includes other chemicals and minerals and than make it highly corrosive to exposed pressure sensor components.

Select materials that are going to provide long term corrosion free protection to the type of water the pressure sensor will be immersed. Groundwater can contain high level of minerals creating a acidic or alkaline solution, and seawater is highly corrosive to many metals including stainless steel.

Underwater cable termination

If the electrical connection to the pressure sensor is to be terminated underwater then it becomes difficult to provide a true atmospheric pressure reference. This is required for vented gauge reference pressure sensors which rely on a connection between surface ambient air pressure and the rear or negative side of the measurement diaphragm. However, many underwater applications do not require a surface atmospheric pressure reference, and instead the sensor is referenced to the ambient air pressure inside a watertight enclosure where the cable is terminated. Alternatively an absolute, sealed gauge or differential pressure range can be used, since either of these do not need a physical reference pressure or a vented reference tube running through the cable.