Select a calibration equipment for calibrating suction pressure measuring devices, and generating suction pressure for setting calibration points.

Products

DM01 Multi-Range High Accuracy Pressure Gauge - High precision digital pressure gauge with 0.05% full scale accuracy, exchangeable pressure range modules from 100 mbar (1.5 psi) up to 400 bar (6000 psi).

DM01 Multi-Range High Accuracy Pressure Gauge - High precision digital pressure gauge with 0.05% full scale accuracy, exchangeable pressure range modules from 100 mbar (1.5 psi) up to 400 bar (6000 psi). PGS40 Mid Pressure Calibration Hand Pump - PGS40 pneumatic hand pump for applying test and calibration pressures with precision from -0.96 up to 40 bar gauge.

PGS40 Mid Pressure Calibration Hand Pump - PGS40 pneumatic hand pump for applying test and calibration pressures with precision from -0.96 up to 40 bar gauge.

Applications

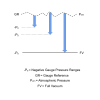

Vacuum sensor control system set-point tester for 0 to -0.95 bar/13.8 psi - Precision vacuum pump and gauge tester for verifying the vacuum set-points of sensors connected to a control system.

Vacuum sensor control system set-point tester for 0 to -0.95 bar/13.8 psi - Precision vacuum pump and gauge tester for verifying the vacuum set-points of sensors connected to a control system.