Pressure indicator transmitters have a digital indicator for providing a local indication of pressure reading, and a 4-20 milliamp output pressure transmitter for sending an analogue signal to control & monitoring instrumentation.

Pressure indicator transmitters provide a vital dual capability for industrial and research applications by combining an easily readable local digital pressure display with a robust 4-20mA analogue output signal. These instruments allow for immediate on-site verification of process pressures, crucial for operational checks and troubleshooting, while simultaneously transmitting accurate data to remote monitoring and control systems. Key advantages include loop-powered displays that simplify installation by drawing power from the 4-20mA signal itself, and user-scalable indicators that can be configured to display various engineering units or a percentage directly at the point of measurement, enhancing convenience for engineers and technicians.

16 bar, 200°C steam pressure transmitter and gauge - Combined pressure transmitter and indicator in one package with the option for use with high temperature media such as steam at 200°C

16 bar, 200°C steam pressure transmitter and gauge - Combined pressure transmitter and indicator in one package with the option for use with high temperature media such as steam at 200°C 10 bar g steam pressure transmitter, indicator and PNP switch - Steam pressure transmitter with LED display indicator for measuring 0 to 10 bars with in-built temperature reducer

10 bar g steam pressure transmitter, indicator and PNP switch - Steam pressure transmitter with LED display indicator for measuring 0 to 10 bars with in-built temperature reducer

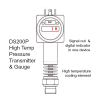

DS200P Sanitary Low Range Pressure Gauge, Switch and Sensor

DS200P Sanitary Low Range Pressure Gauge, Switch and Sensor LEO3 Current or Digital Output Pressure Gauge

LEO3 Current or Digital Output Pressure Gauge DS210 Combined Low Pressure Switch, Indicator and Sensor

DS210 Combined Low Pressure Switch, Indicator and Sensor DS201 Combined Pressure Sensor, Display and Switch

DS201 Combined Pressure Sensor, Display and Switch

- Truck loading monitoring using air cushion pressure - Pressure sensor and remote LED display for installing on a truck to monitor air cushion pressure during loading of a vehicle.

- Hastelloy diaphragm -100 to 50 kPa g range manometer - Small manometer device with membrane protected against corrosive material (chemicals) and which we would prefer to be covered with Hastelloy steel.

- Hot oil pressure transmitter & display to read up to 5 bar at 300degC max - Pressure transmitter with an integral LED loop powered digital display for use with hot oil up to 300 deg. C (max.) over a pressure range of 0-5 bar gauge.

- 10 metre high cylindrical oil tank level gauge and transmitter - Sensor and display for converting a pressure reading to a level reading of a 10 metre high cylindrical oil tank.

- Autoclave pressure sensor and display with 10 bar range - We are looking for a autoclave pressure sensor and display for connecting to a laboratory steam sterilising autoclave and operates at about 10 bar @160°C

- Low pressure methane gas transmitter with display and switch - I am looking for a 4-20mA pressure transmitter device for measuring the pressure of methane (CH4) gas up to 160 mbar gauge.

DS200 Combined Pressure Switch, Gauge and Sensor

DS200 Combined Pressure Switch, Gauge and Sensor DS201P High Range Flush Pressure Gauge, Switch and Sensor

DS201P High Range Flush Pressure Gauge, Switch and Sensor

Find out more about Pressure Indicator Transmitters to determine which product options and capabilities will best meet your application requirements.

Pressure indicator transmitters offer a distinct advantage by integrating a clear, local digital display with the industry-standard 4-20 milliamp analogue output common to pressure transmitters. This dual functionality serves a critical role in modern industrial processes, providing immediate, on-the-spot pressure readings for personnel while simultaneously feeding precise data to remote control systems, PLCs, SCADA, or data logging equipment. The convenience of a local readout is invaluable for plant operators and technicians performing routine checks, troubleshooting, or commissioning activities, allowing them to directly observe process conditions without needing to consult a central control room or carry portable manometers.

A key technical feature enhancing the utility of these devices is the loop-powered nature of the integrated digital indicator. This means the display draws its power directly from the 4-20mA current loop generated by the transmitter section, eliminating the need for a separate, dedicated power supply and associated wiring for the visual display. This simplification results in reduced installation costs, less complex wiring designs, and can be particularly beneficial in retrofitting scenarios or in locations where providing additional power sources is challenging or expensive. For design engineers, this feature streamlines system architecture and reduces the overall component count.

The on-board digital indicators are designed for maximum flexibility, typically allowing for user scaling directly at the instrument via accessible push buttons or adjustment potentiometers. This empowers instrument technicians and process engineers to configure the display to show pressure in a wide variety of engineering units, such as psi, bar, kPa, atmospheres, or even as a percentage from 0-100% of the transmitter’s full-scale range. This on-site adjustability ensures the local reading is immediately meaningful to operators in their preferred units of measure, or can be tailored to represent a specific process variable like tank level or flow rate derived from pressure, enhancing clarity and reducing the chance of misinterpretation during critical operations.

Consider the application of monitoring pump discharge pressures on a process skid. An operator can instantly see the local pressure on the indicator transmitter, confirming the pump is operating within its expected parameters, while the 4-20mA signal is concurrently used by the control system to modulate pump speed or trigger alarms if pressure deviates. Similarly, in hydraulic systems, filter condition monitoring, or gas blanketing applications, the ability to have a direct visual pressure reference at the point of measurement, combined with a reliable analogue signal for system automation, proves indispensable for efficient and safe plant operation. This makes pressure indicator transmitters a versatile solution for research engineers conducting pilot studies requiring both immediate visual feedback and data acquisition, as well as for process engineers managing established industrial installations.

Product Help

Specifying pressure indicator transmitter features

Indicator type

A pressure indicator transmitter includes a built-in pressure gauge for reading in-situ.

Do you require LCD, backlit LCD, or an LED display?

A display can be configured to display the pressure reading in different pressure units, or as a % full scale, the 4-20mA output, alarm levels, and calibration values.

Output signal

Typically a pressure transmitter with a built-in display indicator will have a 4-20mA 2 wire current loop signal. This 4-20mA signal may include intrinsically safe or flameproof certification for hazardous areas, and HART communications for use in a process plant with other HART enabled devices.

Alarm switch

Since there is a built-in display it is possible to add alarm contact switches on some pressure indicator transmitters which are easily configurable via the display and menu keys.

The contact switches are normally a solid state type such as PNP or NPN, which keeps the size and wiring to a minimum.

Re-calibration

Depending on the product type it is possible to re-calibrate the 4-20mA output signal and the display reading by adjusting the zero and span setting via the display panel menu buttons.

Turn-down ratio

Turn-down the output signal to re-scale the measured range. The turndown ratio defines how low the range can be reduced. A ratio of 3:1 or 4:1 is possible with simpler lower cost transmitters, and increases to 10:1 or 100:1 with more expensive intelligent transmitters.

Will the pressure indicating transmitter need to be moved or re-purposed to measure over a different range?

Checklist for pressure indicator transmitter requirements

Define your pressure indicator transmitter requirements using this checklist:

- Indicator type?

- Output signal?

- Alarm switch?

- Re-calibration?

- Turn-down ratio?

- Pressure range?

- Electrical connection?

- Process connection?