Battery powered, intrinsically safe pressure data loggers for hazardous zones. Features include configurable logging, event triggers, and data analysis.

Intrinsically Safe (IS) pressure data loggers are vital instruments designed to operate safely and reliably in potentially explosive environments where flammable substances are present. By limiting electrical and thermal energy to prevent ignition, these battery powered devices allow engineers and technicians in sectors like oil and gas, chemical processing, and mining to accurately record pressure data directly within hazardous zones. Featuring configurable logging modes, including event activated recording, and robust data analysis capabilities, IS pressure data loggers provide critical insights for process control, safety compliance, and system diagnostics in challenging industrial settings.

Data logger for ATEX zone 1 area to measure up to 5000 psi - I am looking for a data logger that is ATEX approved for zone 1, battery operated, have ample memory, sample every second, and pressure range to 5kpsi

Data logger for ATEX zone 1 area to measure up to 5000 psi - I am looking for a data logger that is ATEX approved for zone 1, battery operated, have ample memory, sample every second, and pressure range to 5kpsi Monitoring low pressure waste gas in zone 0 hazardous areas - Pressure datalogger for accurately measuring and logging very low, bidirectional waste gas pressures within ATEX Zone 0 and Gas Group IIC hazardous locations. Ideal for portable field calibration and process monitoring.

Monitoring low pressure waste gas in zone 0 hazardous areas - Pressure datalogger for accurately measuring and logging very low, bidirectional waste gas pressures within ATEX Zone 0 and Gas Group IIC hazardous locations. Ideal for portable field calibration and process monitoring.

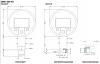

DM01 Multi-Range High Accuracy Pressure Gauge

DM01 Multi-Range High Accuracy Pressure Gauge LEO Record (Ei) Capo Low Pressure Logger

LEO Record (Ei) Capo Low Pressure Logger LEO Record (Ei) Pressure Data Logger

LEO Record (Ei) Pressure Data Logger DM01-500-HD High Range Digital Pressure Gauge

DM01-500-HD High Range Digital Pressure Gauge

Hydraulic Testing Intrinsic Safety Approved Pressure Data Loggers - Intrinsically safe pressure data loggers are essential tools for testing and validating the performance of hydraulic systems in hazardous environments where explosive atmospheres may be present.

Hydraulic Testing Intrinsic Safety Approved Pressure Data Loggers - Intrinsically safe pressure data loggers are essential tools for testing and validating the performance of hydraulic systems in hazardous environments where explosive atmospheres may be present.

Find out more about Intrinsically Safe Pressure Data Loggers to determine which product options and capabilities will best meet your application requirements.

Intrinsically Safe (IS) pressure data loggers are specialized instruments engineered for the precise measurement and recording of pressure data in environments where the presence of flammable gases, vapors, mists, or combustible dusts poses a significant explosion risk. The core design principle of intrinsic safety ensures that the electrical energy and thermal energy within the data logger’s circuitry are limited to levels below those capable of igniting a hazardous atmosphere, even under fault conditions. This is often achieved through techniques such as current and voltage limiting resistors, Zener barriers, or galvanic isolation, eliminating the need for cumbersome and expensive explosion-proof enclosures.

These data loggers are indispensable tools in sectors such as petrochemical processing, offshore oil and gas exploration and production facilities, natural gas transmission and distribution networks, chemical manufacturing plants, mining operations, and pharmaceutical production where volatile solvents might be present. Their application extends to any area classified as a hazardous zone (e.g., Zone 0, 1, 2 under ATEX/IECEx directives or Class I, Division 1, 2 under North American standards). The ability to deploy a battery-powered device directly within these zones without compromising safety protocols is a key advantage, facilitating accurate monitoring at critical points within a process or system.

The operational versatility of IS pressure data loggers allows for the recording of various pressure types, including gauge, absolute, and sometimes differential pressures, across a range of media, from inert gases like air and nitrogen to more aggressive liquids and gases found in industrial processes. Careful consideration of wetted parts material compatibility (e.g., stainless steel, Hastelloy) with the process media is crucial for long-term reliability and accuracy.

Configuration of the data logging process is a critical aspect, offering engineers and technicians flexibility in data acquisition strategies. Users can typically define logging intervals, initiate recordings immediately, schedule delayed starts to coincide with specific operational phases, or implement event-activated recording. Event triggers might be based on pressure thresholds (high or low alarms), rates of change, or external digital inputs, allowing for focused data capture during anomalies, system startups, shutdowns, or specific process cycles. This targeted data acquisition is invaluable for diagnostics, predictive maintenance, and regulatory compliance reporting.

Once the logging campaign is complete, the stored pressure readings are typically downloaded to a PC or laptop via a dedicated interface, which itself must often be used outside the hazardous area or be intrinsically safe. Accompanying software facilitates the analysis of this data, enabling users to generate time-stamped graphs, identify pressure trends, detect spikes or drops, calculate averages, and export data for further manipulation or inclusion in technical reports. This detailed analysis is essential for process optimization, safety audits, and ensuring the integrity of pressure-sensitive systems operating within potentially explosive environments. The longevity of the battery and its specific type are also critical design considerations, ensuring sufficient operational life for extended monitoring tasks while adhering to the strict energy limitations imposed by intrinsic safety standards.