Hydraulic system & components testing, intrinsic safety (IS) zone approved operation, pressure reading data storage logger.

Hydraulic systems generate a large force which is are used to move, lift, break or crush objects. Testing hydraulic systems and components is carried out on regular basis to check compliance with reliability, performance and safety requirements. Hydraulic system components such as actuators, valves, pumps, motors, presses and weighing pads all have to be tested to check the component is operating within specified parameters and tolerances.

Products

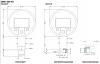

DM01-500-HD High Range Digital Pressure Gauge - The DM01-500 HD high range pressure gauge is available in pressure ranges from 0 to 600, 1000, 1600, 2000 & 2200 bar.

DM01-500-HD High Range Digital Pressure Gauge - The DM01-500 HD high range pressure gauge is available in pressure ranges from 0 to 600, 1000, 1600, 2000 & 2200 bar. LEO Record (Ei) Pressure Data Logger - LEO Record combined digital manometer & pressure data logging instrument for recording pressures & temperatures that can store up to 57,000 readings.

LEO Record (Ei) Pressure Data Logger - LEO Record combined digital manometer & pressure data logging instrument for recording pressures & temperatures that can store up to 57,000 readings.

Related Product and Application Guides

Intrinsically safe approved instrumentation can be installed in hazardous area zones and connected to other appropriate intrinsically safe equipment. Intrinsic safety is achieved by limiting the amount of electrical power that can enter the protected zone by incorporating zener diode or isolation transformer barriers, ensuring a specified surface temperature is not exceeded, and preventing electrical discharges which may otherwise ignite a potentially explosive atmosphere.

A pressure data logger is an instrument which incorporates a pressure measuring device with a data storage memory and firmware, or separate computer software and interface to facilitate the recording of pressure values. A pressure data logger can be setup by the user to commence recording at a certain time or event, at a preset sample rate. Once the pressure data logger has completed collecting data, the software can be utilised to analyze or transfer the data to a data file for export to another application program.