Sensors & instrumentation that have a high frequency response measurement signal output or input.

Sensors & instrumentation that have a high frequency response measurement signal output or input.

These instruments are capable of rapidly updating displayed readings or recording data to capture measurements which require a fast dynamic response from the sensing technology and signal conditioning electronics.

Pressure instruments for recording data with very short time intervals via a PC. Analyse characteristics of changing pressures to millisecond resolution.

Display graphical plots on transfer data in tabulated form. 4-20mA, 5 volt or 10 volt output pressure sensors which have high frequency response amplifiers for monitoring rapidly changing pressures.

Digital readouts with quick update displays which refresh several times per second.

Capture the maximum reached pressure more accurately using a pressure gauge that refreshes its peak reading memory at a high frequency.

In test and research applications where one of the key measurement parameters is rapidly changing it is necessary to use instrumentation that can collect readings at a very high frequency. For example if the position of an actuator arm is moving in and out at a frequency of 500 Hz, the position measurement device will need to measure in the order of x1000 Hz to provide enough readings to characterise how the position is changing during one full cycle of movement.

The frequency of response is typically limited by the sensing technology or the signal conditioning electronics, regardless of how fast either one is, the slowest one will always dictate the overall measurement response. For example a very fast microprocessor combined with a slow reacting temperature probe, will provide lots of data points from the temperature probe. If the temperature changes faster than the response of the temperature probe then many of the data points will lag behind the actual temperatures at the time they were recorded or transmitted.

TPS Strain Gauge Pressure Sensor - Strain gauge pressure sensor with a millivolt output direct from a four arm wheatstone bridge strain gauge circuit in pressure ranges from 10 up to 1000 bar gauge.

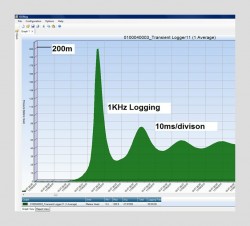

TPS Strain Gauge Pressure Sensor - Strain gauge pressure sensor with a millivolt output direct from a four arm wheatstone bridge strain gauge circuit in pressure ranges from 10 up to 1000 bar gauge. High Frequency Response 1000 Hz Sampling Rate Pressure Data Logger - The Triton IT Pressure Transient data logger can detect and log pressure surge data up to 1000 readings per second without interfering with the main recordings.

High Frequency Response 1000 Hz Sampling Rate Pressure Data Logger - The Triton IT Pressure Transient data logger can detect and log pressure surge data up to 1000 readings per second without interfering with the main recordings. DMP320 0.5 msec Fast Response Pressure Sensor - High frequency response pressure sensor with a better than 0.5 millisecond response time and internal digital signal conditioning that samples readings at a rate of 10 kilohertz.

DMP320 0.5 msec Fast Response Pressure Sensor - High frequency response pressure sensor with a better than 0.5 millisecond response time and internal digital signal conditioning that samples readings at a rate of 10 kilohertz. IMP Ceramic Strain Gauge Pressure Transducer - Ceramic strain gauge pressure transducer with a 2mV/V or 10mV/V output signal in pressure ranges from 1 bar up to 700 bar gauge or absolute.

IMP Ceramic Strain Gauge Pressure Transducer - Ceramic strain gauge pressure transducer with a 2mV/V or 10mV/V output signal in pressure ranges from 1 bar up to 700 bar gauge or absolute. UPS-HSR USB Pressure Sensor with High Sample Rate Logging - USB ready digital pressure sensor for recording pressures with a high speed sample rate of up to 1 kHz to a computer.

UPS-HSR USB Pressure Sensor with High Sample Rate Logging - USB ready digital pressure sensor for recording pressures with a high speed sample rate of up to 1 kHz to a computer. LEO1 (Ei) Digital Pressure Gauge - Battery powered digital gauge with an accuracy of 0.1% full scale in pressure ranges from -1 to 3 bar up to 1000 bar.

LEO1 (Ei) Digital Pressure Gauge - Battery powered digital gauge with an accuracy of 0.1% full scale in pressure ranges from -1 to 3 bar up to 1000 bar. TM Silicon Strain Gauge Pressure Transducer - Passive compensated pressure transducer with a four arm semiconductor Wheatstone bridge circuit which produces a 100 millivolt with a 10 volt excitation.

TM Silicon Strain Gauge Pressure Transducer - Passive compensated pressure transducer with a four arm semiconductor Wheatstone bridge circuit which produces a 100 millivolt with a 10 volt excitation.