Pressure gauges for capturing measurements and storing them on internal memory or transferring to a computer in real time.

In addition to logging pressure measurements, these data-logging pressure gauges will also display actual pressure readings like any other dedicated digital pressure gauge.

You can connect a data logging pressure gauge to a laptop or desktop computer to transfer real time or stored pressure readings, and produce charts or tabulated data, logged at selected time intervals.

A communication link between the PC and datalogging pressure gauge is provided for RS232 or USB serial ports and PC software for managing the data transfer and analysis options.

Products

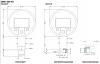

DM01 Multi-Range High Accuracy Pressure Gauge - High precision digital pressure gauge with 0.05% full scale accuracy, exchangeable pressure range modules from 100 mbar (1.5 psi) up to 400 bar (6000 psi).

DM01 Multi-Range High Accuracy Pressure Gauge - High precision digital pressure gauge with 0.05% full scale accuracy, exchangeable pressure range modules from 100 mbar (1.5 psi) up to 400 bar (6000 psi). DM01-500-HD High Range Digital Pressure Gauge - The DM01-500 HD high range pressure gauge is available in pressure ranges from 0 to 600, 1000, 1600, 2000 & 2200 bar.

DM01-500-HD High Range Digital Pressure Gauge - The DM01-500 HD high range pressure gauge is available in pressure ranges from 0 to 600, 1000, 1600, 2000 & 2200 bar.

LEO Record (Ei) Capo Low Pressure Logger

LEO Record (Ei) Capo Low Pressure Logger LEO3 Current or Digital Output Pressure Gauge

LEO3 Current or Digital Output Pressure Gauge LEX1 (Ei) High Accuracy Digital Pressure Gauge

LEX1 (Ei) High Accuracy Digital Pressure Gauge LEO Record (Ei) Pressure Data Logger

LEO Record (Ei) Pressure Data Logger

Applications

-1 to 20 kg/cm² digital pressure gauge for live computer data acquisition - The LEX1 will allow you to read in kg/cm2 over the range specified, and send live readings to a PC computer using the optional USB converter and software.

-1 to 20 kg/cm² digital pressure gauge for live computer data acquisition - The LEX1 will allow you to read in kg/cm2 over the range specified, and send live readings to a PC computer using the optional USB converter and software. Hydraulic puller-tensioner bar pressure to kilonewton load HMI display & logger - We are looking for an indicator with HMI software to show a machine operator the amount of force generated by a hydraulic puller-tensioner used for power line stringing.

Hydraulic puller-tensioner bar pressure to kilonewton load HMI display & logger - We are looking for an indicator with HMI software to show a machine operator the amount of force generated by a hydraulic puller-tensioner used for power line stringing. 5000 psi pressure gauge with USB & software for recording - Pressure gauge with LCD digital display and thread mount, for measuring to 5000 psi and displaying reading in pounds per square inch pressure units.

5000 psi pressure gauge with USB & software for recording - Pressure gauge with LCD digital display and thread mount, for measuring to 5000 psi and displaying reading in pounds per square inch pressure units. 30 psi absolute portable calibration data logging air pressure gauge with 1/4 NPT male fitting - Digital display pressure gauge for portable calibration use in air measurement applications, capable of measuring 0 to 30 psi abs pressure with 0.1% accuracy and connected using a 1/4 NPT male fitting. Also includes USB, logger, and data transfer software.

30 psi absolute portable calibration data logging air pressure gauge with 1/4 NPT male fitting - Digital display pressure gauge for portable calibration use in air measurement applications, capable of measuring 0 to 30 psi abs pressure with 0.1% accuracy and connected using a 1/4 NPT male fitting. Also includes USB, logger, and data transfer software.

40 inH2O g peak/valley storing pressure gauge for monitoring gas feed fluctuations

40 inH2O g peak/valley storing pressure gauge for monitoring gas feed fluctuations PC logging USB interface 200 bar range portable freshwater pressure gauge

PC logging USB interface 200 bar range portable freshwater pressure gauge 1000 bar PC logging pressure gauge for connecting to computer USB port

1000 bar PC logging pressure gauge for connecting to computer USB port 20 bar digital pressure gauge with USB connection and PC logging

20 bar digital pressure gauge with USB connection and PC logging Pressure gauge for recording pressure 0-6 bar on PC/Laptop

Pressure gauge for recording pressure 0-6 bar on PC/Laptop 1000 psi g data logging pressure gauge

1000 psi g data logging pressure gauge 10 barg dual pressure & temperature pressure logging gauge

10 barg dual pressure & temperature pressure logging gauge R21/R22 refrigerant digital pressure gauge to read up to 500psi

R21/R22 refrigerant digital pressure gauge to read up to 500psi

- 30 ounces per square inch range pressure gauge with built-in logger

- 10 bar air pressure gauge for connecting to laptop

- 6000 psi recording digital pressure gauge with intrinsic safety

- 3000 pascal range data-logging manometer for use on air handling systems

- 5000 psi USB interface pressure gauge with 1/4 NPT male fitting

Product Help

Specifying pressure gauges with data logging functionality

Computer interface type

How do you want to transfer logged data from the pressure gauge to a computer, USB, RS485, Ethernet, Bluetooth, memory stick, mobile cellular network, or WiFi?

Viewing readings during logging

How do you want to view saved readings during logging?

Do you want to view a logging trend chart on the pressure gauge display or only on a computer screen via a communications link?

Memory size

Does the pressure gauge need to store data internally?

What is the maximum number of readings you need to collect in one logging session?

How many logging sessions will you need to run before the next opportunity to upload data from the pressure gauge?

Logging rate

What will be the minimum time interval you need between saved pressure data points?

How quickly do you want to collect pressure readings, is there a very brief pressure change event that you want to be able to record, or is it only a gradual trend in pressure change you are interested in recording with the pressure gauge?

Test reports and certificates

Do you need to generate your own printed reports or certificate to document the logging results?

Are you using the pressure gauge to carry out leak tests or performance tests, and need a software solution to produce a test report as documentation evidence of the test?

Exporting logged data

Will you need to export the logged data to another software program in order to process the test results ?

Do you need to save the recorded results or convert a data file to a common file format such as .txt (text) or .csv (comma separated values), so that it can be easily imported into another software program such as Excel or Google Sheets?

Checklist for data logging pressure gauge requirements

Define your data logging pressure gauge requirements using this checklist:

- View readings during logging?

- Memory size?

- Minimum logging rate?

- Computer interface type?

- Test reports and certificates?

- Exporting log data?

- Operating pressure range?

- Pressure reference?

- Power supply?

- Installation type?

- Accuracy?

- Resolution?

- Pressure connection fitting?

- Other measurement parameters?

- Number of pressure input channels?