Economical corrosion resistant ceramic diaphragm pressure sensor for measuring water pressure over a 10 bar gauge pressure range on an automotive test rig and generating a 0 to 5 volts output signal.

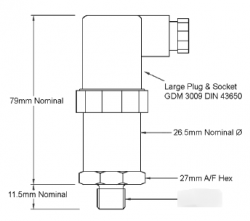

This configuration of the IMP is wired to automotive test monitoring instrumentation using a large DIN plug connector and installed using a G1/4 male DIN 3852 process fitting.

This standard version of the IMP pressure sensor has a corrosion resistant ceramic based diaphragm sensing module with thick film strain gauges and a completely dry construction with no oil filled isolation. The ceramic sensor module is sealed within the G1/4 male DIN 3852 process connector and electronic housing using a Viton elastomer O ring.

The measurement accuracy is +/-0.25% FS best straight line at room temperature, with an additional thermal zero shift error of 0.04% FS/°C and thermal span shift error of 0.015% FS/°C.

IMP Water Test Pressure Sensor

- SKU ID: s1-imp-12-16774

- Pressure Range: 10

- Units: bar

- Pressure Reference: Gauge (G)

- Output Signal: 0 – 5V, 3-wire (6)

- Non-Linearity and Hysteresis: 0.25% FS (standard) (A)

- Thermal Zero Shift: 0.04% FS per °C (standard) (4)

- Thermal Span Shift: 0.015% FS per °C

- Electrical Connection: Large DIN plug (standard) (B)

- Process Connection: G1/4 male DIN 3852 (A)

- Media Exposed Seals: Viton (standard)(V)

- Special Requirements: Standard (000)