Pressure gauges with LCD readouts for displaying pressure readings and other information such as pressure units, stored maximum/minimum values, set-up menu screens.

LCD digital display pressure gauges include a user interface operated by front panel keys to navigate a menu to allow the configuration of the pressure gauge for different applications.

Liquid Crystal Displays (LCD) extend the battery life of pressure gauges allowing so they can be used over long periods of time to monitor process pressures.

Products

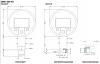

Baroli 02 Precision Digital Pressure Gauge - Precision digital pressure gauge with ranges from 100 mbar (1.5 psi) up to 600 bar (9000 psi) for measuring to an accuracy of 0.125% FS BSL.

Baroli 02 Precision Digital Pressure Gauge - Precision digital pressure gauge with ranges from 100 mbar (1.5 psi) up to 600 bar (9000 psi) for measuring to an accuracy of 0.125% FS BSL. Baroli 05 Industrial Digital Pressure Gauge - Digital pressure gauge with ranges from 0.6 bar (9 psi) up to 600 bar (9000 psi) gauge or absolute and an accuracy of 0.25% full scale.

Baroli 05 Industrial Digital Pressure Gauge - Digital pressure gauge with ranges from 0.6 bar (9 psi) up to 600 bar (9000 psi) gauge or absolute and an accuracy of 0.25% full scale.

DM01-500-HD High Range Digital Pressure Gauge

DM01-500-HD High Range Digital Pressure Gauge DM01 Multi-Range High Accuracy Pressure Gauge

DM01 Multi-Range High Accuracy Pressure Gauge Baroli 02P Low Range Flush Diaphragm Digital Pressure Gauge

Baroli 02P Low Range Flush Diaphragm Digital Pressure Gauge LEX1 (Ei) High Accuracy Digital Pressure Gauge

LEX1 (Ei) High Accuracy Digital Pressure Gauge

Applications

10 bar multi-unit select and min/max recall digital pressure gauge - Digital pressure gauge for measuring 0 to 10 bar gauge with user adjustable measurement units

10 bar multi-unit select and min/max recall digital pressure gauge - Digital pressure gauge for measuring 0 to 10 bar gauge with user adjustable measurement units

Product Types

Digital Manometers - Select a digital manometer for checking and testing low range pneumatic pressures. Select manometers by type of pressure connector, pressure media, precision and pressure range.

Digital Manometers - Select a digital manometer for checking and testing low range pneumatic pressures. Select manometers by type of pressure connector, pressure media, precision and pressure range.