Pressure data loggers for demanding hydraulic test applications. Verify performance, reliability, and safety of actuators, pumps, valves & systems.

Pressure data loggers specifically designed for hydraulic testing are essential tools for engineers and technicians needing to capture detailed pressure information during system and component evaluation. These instruments go beyond simple gauges, recording high-speed pressure transients, variations over extended cycles, and precise profiles necessary for validating performance against design specifications, ensuring operational reliability, diagnosing faults in components like actuators, valves, and pumps, and confirming compliance with safety standards in demanding applications from R&D labs to production lines and field maintenance.

Wireless hydraulic prop pressure testing indicator, logger & multiple sensors - We work with hydraulic propping equipment used in excavation support and we are looking into pressure testing and monitoring with a network of pressure instruments.

Wireless hydraulic prop pressure testing indicator, logger & multiple sensors - We work with hydraulic propping equipment used in excavation support and we are looking into pressure testing and monitoring with a network of pressure instruments. Hydraulic press logger for recording up to 10,000 psi with 0.1 sec logging rate - Recording pressures up to 10,000 psi on a hydraulic press with a fast logging rate.

Hydraulic press logger for recording up to 10,000 psi with 0.1 sec logging rate - Recording pressures up to 10,000 psi on a hydraulic press with a fast logging rate.

LEO Record (Ei) Pressure Data Logger

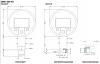

LEO Record (Ei) Pressure Data Logger DM01-500-HD High Range Digital Pressure Gauge

DM01-500-HD High Range Digital Pressure Gauge ADT681 Digital Pressure Gauge

ADT681 Digital Pressure Gauge

- Hydraulic puller-tensioner bar pressure to kilonewton load HMI display & logger - We are looking for an indicator with HMI software to show a machine operator the amount of force generated by a hydraulic puller-tensioner used for power line stringing.

- 5000 psi data logging gauge for measuring hydraulic pressures - Monitor and log high pressure hydraulics with this 5800 psi data logging gauge. Features USB connection and software for data transfer.

- Hydraulic piston recorder & display with 2 pressure sensors - Monitor and record hydraulic piston parameters with the MultiCon CMC-N16 and TPSA high-pressure transmitters. This system displays pressure, calculates force/torque, and logs data for analysis.

Hydraulic Testing Intrinsic Safety Approved Pressure Data Loggers - Intrinsically safe pressure data loggers are essential tools for testing and validating the performance of hydraulic systems in hazardous environments where explosive atmospheres may be present.

Hydraulic Testing Intrinsic Safety Approved Pressure Data Loggers - Intrinsically safe pressure data loggers are essential tools for testing and validating the performance of hydraulic systems in hazardous environments where explosive atmospheres may be present.

Find out more about Hydraulic Testing Pressure Data Loggers to determine which product options and capabilities will best meet your application requirements.

Pressure data loggers engineered for hydraulic testing applications provide crucial insights beyond simple peak pressure readings, enabling detailed analysis of system and component behaviour under operational stress. These instruments are indispensable for capturing dynamic pressure fluctuations, transient events, and long-term trends during rigorous test cycles designed to verify reliability, performance, and safety compliance in hydraulic circuits. Engineers and technicians rely on this stored pressure data to validate designs, diagnose faults, and confirm adherence to specific operational parameters and tolerances.

The demands of hydraulic testing necessitate data loggers with specific capabilities. Capturing rapid pressure spikes generated during valve actuation, pump start-up, or potential hydraulic shock (water hammer) requires high sampling rates, often significantly faster than those needed for static or slowly changing processes. Furthermore, the ability to record pressure profiles over extended periods, such as during endurance or fatigue testing of actuators or hydraulic motors, demands substantial onboard memory capacity to store large datasets without interruption. Analysis of this time-stamped data allows for precise characterization of component response times, pressure decay rates during leak testing, or consistency across thousands of operational cycles.

Specific applications highlight the utility of pressure data logging in hydraulic component verification. When testing actuators, logging pressure alongside position or force can verify performance curves and identify issues like seal bypass or sticking. For hydraulic valves, loggers capture pressure drops during flow, response times to control signals, and can help quantify internal leakage rates under sustained pressure. Evaluating pump performance involves logging output pressure against flow rate or drive speed to map efficiency curves and detect anomalies like pressure ripple. Similarly, testing hydraulic presses requires consistent pressure application, which data loggers can verify cycle-after-cycle, while logged data from hydraulic weighing pads confirms calibration accuracy and load distribution.

These specialized loggers are frequently deployed in demanding environments, ranging from research and development labs refining new component designs to manufacturing facilities performing end-of-line quality control checks on assembled hydraulic systems. Dedicated test benches simulating specific operational conditions for components like pumps, motors, or cylinders heavily utilize pressure data logging for performance validation. Field service and maintenance technicians also employ portable pressure loggers for on-site troubleshooting of construction machinery, industrial presses, or aerospace hydraulic systems, helping to pinpoint intermittent faults or verify system health after repairs. The logged data provides objective evidence for compliance reports, failure analysis, and system optimization efforts. The ability to trigger logging based on specific pressure thresholds or external events further enhances their utility in capturing specific moments of interest during complex test sequences.