Measure extreme hydraulic pressures with our robust, voltage-output (0-5V, 0-10V) transducers. Designed for actuators, presses, & pumps. Ideal for demanding applications in automotive, aviation, and material testing.

Our high-pressure hydraulic transducers with analog voltage output are engineered for precise and reliable pressure measurement in the most demanding industrial and research applications. Constructed from robust stainless steel, these sensors are built to withstand extreme pressures and corrosive fluids, making them ideal for monitoring hydraulic actuators, presses, pumps, valves, elevators, and material testing equipment. The analog voltage output ensures seamless integration with a wide range of data acquisition and control systems, providing critical real-time data for process optimization and safety.

Custom pressure sensor for mining haul truck suspension hydraulics - Measuring high-pressure suspension hydraulics on heavy mining trucks with a custom-engineered pressure transducer which solved challenges of vibration, contamination, and a non-standard process connection.

Custom pressure sensor for mining haul truck suspension hydraulics - Measuring high-pressure suspension hydraulics on heavy mining trucks with a custom-engineered pressure transducer which solved challenges of vibration, contamination, and a non-standard process connection. 200 bar pressure sensor to interface with Arduino board - I want to use a sensor interfaced to a Arduino board to measure pressure in range of 0 to 200 bar in hydraulic brake line hoses.

200 bar pressure sensor to interface with Arduino board - I want to use a sensor interfaced to a Arduino board to measure pressure in range of 0 to 200 bar in hydraulic brake line hoses.

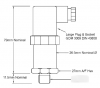

TPSA Precision High Pressure Transducer

TPSA Precision High Pressure Transducer DMP 335 All Welded Stainless Steel Diaphragm Pressure Sensor

DMP 335 All Welded Stainless Steel Diaphragm Pressure Sensor TPHADA Ultra High Range Pressure Sensor

TPHADA Ultra High Range Pressure Sensor DMP334 Hydraulic Pressure Transducer for Very High Pressures

DMP334 Hydraulic Pressure Transducer for Very High Pressures

- 60000 psi hydraulic pressure transducer with 0-5Vdc signal out - All-welded stainless steel pressure transducer with 0-5v output for high-pressure hydraulic applications up to 60,000 psi.

- Brake line pressure sensor to measure up to 4000 psi g with 0-10Vdc signal - Rugged all-welded pressure sensor for hydraulic brake lines.1 0-10Vdc output, 4000 psi max. Ideal for demanding applications.

Find out more about Hydraulic Analog Voltage Signal Pressure Transducers to determine which product options and capabilities will best meet your application requirements.

These hydraulic pressure transducers are specifically engineered to provide precise pressure measurements within high-pressure hydraulic systems, utilizing an analog voltage output signal. The voltage output is typically linear and proportional to the applied hydraulic pressure, allowing for straightforward integration with data acquisition systems, PLCs, and display instrumentation. The selection of specific voltage output ranges, such as 0-5Vdc or 0-10Vdc, is often determined by the compatibility requirements of the downstream monitoring or control equipment.

Crucially, these transducers are designed to endure extreme pressures, often exceeding several thousand psi, frequently encountered in demanding hydraulic applications. The robust construction, commonly utilizing specialized high-yield strength stainless steel alloys such as 17-4 PH or 15-5 PH, contributes to the sensor’s ability to withstand significant pressure spikes and cyclical loading, crucial for reliability in dynamic hydraulic systems.

The choice of stainless steel also extends to the wetted parts, ensuring compatibility with a wide range of hydraulic fluids, including those with aggressive chemical properties, such as those found in the automotive and aviation industries. The sensor’s diaphragm design, often incorporating a thicker, more rigid diaphragm than lower-pressure counterparts, contributes to its overpressure resistance and ability to resist damage from pressure transients.

Specifically, these transducers find applications in monitoring the operation of hydraulic actuators, where precise pressure feedback is essential for controlling position, force, or speed. They are equally vital in monitoring hydraulic presses, providing crucial data for process control and safety interlocks.

Installation in high-pressure hydraulic pumps benefits from these transducers’ capability to monitor discharge pressures, thereby allowing for optimized system performance and early detection of potential pump malfunctions, such as cavitation or blockage. They are also well-suited for use in the demanding environments of hydraulic valves, providing feedback on control pressures.

In the lifting environment, the transducers are found in hydraulic elevators, where they contribute to smooth and safe operation by monitoring hydraulic line pressures.

Their high level of accuracy, and robustness make them suitable for incorporation into material test equipment, where they provide reliable measurement of forces exerted by hydraulic systems during tensile, compression, and fatigue testing. They are indispensable components in other specialized high-range hydraulic apparatus where dependable pressure readings are needed.