Pressure gauges that connect to your PC for simultaneous local pressure indication and digital data transfer. Includes software for analysis and storage.

Computer interface pressure gauges provide a vital link between physical pressure measurement and digital data analysis, offering connectivity via USB or RS232 to computers for real-time display and storage of pressure readings. These instruments are essential for engineers and technicians, allowing for the creation of detailed pressure trend graphs and often coming equipped with PC software for enhanced data logging and analysis. Their ability to offer simultaneous local pressure indication and remote data acquisition makes them highly suitable for diverse applications, from laboratory research and manufacturing process control to calibration tasks and automated test systems, enabling precise monitoring and informed decision-making.

Pressure gauge for recording pressure 0-6 bar on PC/Laptop - We are looking for a pressure gauge which can be connected with a PC or laptop to record the pressure values directly.

Pressure gauge for recording pressure 0-6 bar on PC/Laptop - We are looking for a pressure gauge which can be connected with a PC or laptop to record the pressure values directly. 10 bar air pressure gauge for connecting to laptop - Digital pressure gauge with PC interface with digital output for displaying and logging pressure readings up to 10 bar g on a laptop computer in real time.

10 bar air pressure gauge for connecting to laptop - Digital pressure gauge with PC interface with digital output for displaying and logging pressure readings up to 10 bar g on a laptop computer in real time.

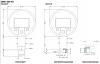

DM01 Multi-Range High Accuracy Pressure Gauge

DM01 Multi-Range High Accuracy Pressure Gauge LEO Record (Ei) Capo Low Pressure Logger

LEO Record (Ei) Capo Low Pressure Logger LEO3 Current or Digital Output Pressure Gauge

LEO3 Current or Digital Output Pressure Gauge LEX1 (Ei) High Accuracy Digital Pressure Gauge

LEX1 (Ei) High Accuracy Digital Pressure Gauge

- 20 bar digital pressure gauge with USB connection and PC logging - 0-20 bar digital pressure gauge with USB connectivity for data logging and analysis on a PC.

LEO Record (Ei) Pressure Data Logger

LEO Record (Ei) Pressure Data Logger DM01-500-HD High Range Digital Pressure Gauge

DM01-500-HD High Range Digital Pressure Gauge ADT681 Digital Pressure Gauge

ADT681 Digital Pressure Gauge

Find out more about Computer Interface Pressure Gauges to determine which product options and capabilities will best meet your application requirements.

Computer interface pressure gauges offer a significant advantage by enabling a direct connection to a desktop or laptop computer, typically utilising ubiquitous USB or robust RS232 serial bus protocols. This connectivity facilitates the real-time display of current pressure readings directly on a computer screen, which is invaluable for continuous monitoring applications. Furthermore, the capability to store each discrete measurement allows for the subsequent generation and analysis of detailed pressure trend graphs, providing insights into process fluctuations or experimental outcomes over time.

These specialised pressure gauges are typically supplied as a complete solution, including a dedicated digital interface cable and accompanying PC software. This software establishes a reliable communication link between the pressure gauge and the computer, ensuring seamless and real-time transfer of pressure readings. This is particularly useful for engineers and technicians who need to capture dynamic pressure changes or log data over extended periods without manual intervention. The ability to configure data logging parameters, such as sampling rates and storage formats, is often a key feature of the provided software.

A notable design feature of these instruments is their dual functionality. They provide a clear, local indication of the process or test pressure directly on the gauge’s display, which is crucial for on-site verification and immediate operational awareness. Simultaneously, this pressure measurement data is uploaded to the connected PC. This concurrent local display and remote data acquisition capability is highly beneficial in environments such as research laboratories for meticulous experiment monitoring, manufacturing facilities for statistical process control, or in calibration laboratories where precise documentation of pressure values against a standard is required.

The PC software accompanying these gauges often extends beyond simple data display and logging. Advanced functionalities might include options for remote tare or zeroing of the gauge, setting alarm thresholds that trigger notifications on the PC, or even performing basic data analysis directly within the application. For engineers designing test rigs or automated systems, the ability to integrate pressure data directly into custom software applications via an API or command-set provided with the RS232 or USB interface can be a critical factor, allowing for more sophisticated control and analysis. For instance, in a component lifecycle testing setup, pressure cycles can be meticulously recorded and correlated with failure modes. Similarly, in pilot plants, process engineers can use this data to optimise operational parameters by observing real-time pressure responses to adjustments.